Andrew Hand

-

Read more ...

At PSW Paper & Print we are excited to share that Onyx Graphics is now officially certified for the HP Latex 730 and 830 printer series, continuing our long-standing partnership with HP to bring reliable, high-performance print solutions to professionals worldwide.

This certification goes beyond compatibility—it means HP Latex 730/830 users can confidently run Onyx RIP and colour management software with full support and optimsed performance. Onyx Graphics powerful solutions are tested and verified to match the unique capabilities of these new-generation printers, including:

- Outstanding media versatility across indoor and outdoor applications

- Vibrant, high-contrast output—even at production speeds

- White ink and multi-layer print support

- Automation and job preparation tools for streamlined workflows

When combined, Onyx software and the HP Latex 730/830 platform deliver a complete print environment that’s production-ready and performance-proven.

Certified Workflow, Powered by Onyx

This certification gives customers the confidence to get the most out of their equipment—knowing that Onyx software is built to support every layer of the job, from file setup to final output. Together with HP’s advancements in print hardware, Onyx brings unmatched flexibility, color control, and productivity to print businesses of all sizes.

“Certification for the HP Latex 730 and 830 series reaffirms Onyx’s focus on delivering precision, reliability, and innovation to the print industry. It ensures our customers can confidently use Onyx software to get the most out of their print environments with the consistency and control they expect from us.”

— Peter Eze, Director of Global Sales, Onyx GraphicsWhether you’re producing signage, décor, vehicle wraps, or retail graphics, Onyx gives you the tools to move faster, work smarter, and deliver with confidence.

About Onyx Graphics, Inc.

Leading the market since 1989, Onyx Graphics is dedicated to helping customers increase productivity, reduce costs, and gain a competitive edge with superior software solutions for the print industry. Innovative, productive, and delighted customers around the globe help motivate the company to develop and enhance its leading-edge technologies. Global channel partnerships and longstanding relationships with printer manufacturers position Onyx Graphics as a market leader in powerful, reliable, large-format printing workflow and print business software solutions.

-

Read more ...

At ISA Sign Expo 2025, HP will announce the HP Latex 730 and HP Latex 830 Printer Series, its latest generation of water-based HP Latex large-format printing solutions. Following last month’s innovations announced at HP Amplify — including the all-in-one HP Latex R530 and HP PrintOS Production Hub — the unveiling of the new series reinforces HP’s ongoing commitment to innovation in Large Format printing, delivering an unrivaled portfolio of hardware, software solutions and services.

The HP Latex 730 and HP Latex 830 are designed to deliver high-impact print quality, enhance productivity and costs for small and medium-sized Print Shops (PSPs) while continuing to differentiate with a sustainability edge.

High-Value Output with Consistent Quality

With the new colour pipeline, HP Pixel Control, the latest generation of inks and printhead architecture, these advanced printers deliver elevated print quality with maximum consistency.

HP Pixel Control is the digital colour pipeline that enables PSPs to deliver a more robust and consistent image quality at a lower number of passes, allowing customers to print uniform solid colours and greater detail. Additionally, enhanced colour consistency and the ability to create colour profiles with the HP Embedded Spectrophotometer allows PSPs to confidently repeat print jobs across various media types without compromising quality.

These printers are a powerful tool for diverse printing needs. Equipped with HP Latex Ink to deliver vivid colours and universal user-replaceable HP Latex Printheads to deliver sharp 4-point text, PSPs can print a wide range of applications – including branded campaigns, décor, and titled graphics – benefiting now from automated double-sided printing.

“One of the top highlights I’m seeing with this printer is that I’m getting finer details, banding reduction and text sharpness at lower pass modes”, said Andreas Griess, Owner and Managing Director of DCO Digitaldruck Centrum Oldenburg GmbH.

HP Latex 730 / 730 W Series Printers

Optimised Productivity and Reduced Waste

The new HP Latex Series is engineered to simplify production and optimise printing processes. Rapid production speeds significantly reduce printing time, while instant drying prints eliminate waiting times so more jobs can be done in less time. When coupled with the recently introduced HP PrintOS Production Hub software, PSPs can further enhance their operations by simplifying print workflows, order management, and remote production from a centralised, real-time platform.

Productivity and time-saving innovations have been considered at every step of the printing process, from spindle-less front-loading to facilitate quick and easy media loading, to the new output platen which minimises material waste by allowing tighter media control of each print job. PSPs can also optimise inventory management with the new universal printheads and a new long-life maintenance cartridge with an extended lifespan by at least 50%. The HP Latex 830 is enhanced to further reduce running costs, featuring 3-liter HP ink cartridges that can be replaced without halting operations.

Each enhancement delivers a smoother, more efficient workflow that enables faster job turnaround and lower total cost of production – ideal for smaller teams when managing multiple jobs in high-mix, fast-paced large format print production.

“With the new HP Latex 730 and HP Latex 830 series, the beauty is on the inside. It’s the key things that really make a difference, from our new colour pipeline HP Pixel Control to the new output platen that enables PSPs to print from the leading edge, we’re bringing innovation in this new series to deliver unrivalled quality, enhanced production and sustainability” said Daniel Martinez, Global Head and General Manager of HP Large Format Business.

HP Latex 830 / 830 W Series Printers

Leading the Way with Sustainable Solutions

Furthering HP’s commitment to operational efficiency and sustainability, the HP Latex 730 and 830 join the HP Latex 630 as EPEAT Climate+ registered printers, the only printers in the signage industry with this certification. The HP Latex Series supports a more comfortable work environment while helping PSPs meet the growing demand for sustainable, high-impact print applications with water-based, odourless, and UL ECOLOGO-certified HP Latex inks, low emissions, and compatibility with fiber-based recyclable media.

PSPs can also advance their sustainability journey with the Sustainability Amplifier program software, which offers self-assessment tools, personalised recommendations, and expert-developed best practices to improve their environmental impact. Plus, reduce plastic waste with returnable supplies, including the new maintenance cartridge, via HP Planet Partners.

Preston Jordan, Owner and Founder at US-based Digital Precision, a full service environmental graphics production house highlighted the importance of today’s innovations reflecting the growing demand for sustainability, Jordan highlighted “Corporate clients are increasingly interested in sustainability. They’re inquiring about actions to take and how to incorporate sustainability into their marketing messages. They aim to communicate technological efforts to meet current sustainability expectations in an unsustainable industry.”

Availability

The HP Latex 730 and 830 Printer Series will be available worldwide starting May 5, 2025.

HP is also announcing global availability of the breakthrough innovations announced at HP Amplify. The all-in-one compact HP Latex R530 Printer - capable of handling both rigid and flexible media— is general available starting today, and the world’s only large-format software that merges order management and remote production control into a centralised, real-time platform, HP PrintOS Production Hub, will be globally available starting May 20.

About HP

HP Inc. (NYSE: HPQ) is a global technology leader and creator of solutions that enable people to bring their ideas to life and connect to the things that matter most. Operating in more than 170 countries, HP delivers a wide range of innovative and sustainable devices, services and subscriptions for personal computing, printing, 3D printing, hybrid work, gaming, and more. For more information, please visit: http://www.hp.com.

-

Read more ...

The world of garment printing is evolving rapidly, introducing innovative technologies that make printing on textiles faster, more efficient, and more versatile than ever. Among these advancements, Direct to Garment (DTG) and Direct to Film (DTF) printing stand out as game-changing methods for producing vibrant, high-quality designs on a variety of materials.

Whether you’re a seasoned professional or exploring new ways to expand your printing business, understanding new technologies is key to staying ahead in a competitive industry.

In this blog, we’ll break down how DTG and DTF printing work, explore the benefits of each, and show you how SAi Flexi DTF DTG software makes these processes more streamlined and accessible than ever.

Ready to dive into the details? Let’s get started.

Direct to Garment (DTG) Printing

Direct to garment printing, often known as DTG printing, is the method of using a computer to transfer a digital image to a specialised printer that jets ink directly onto a textile or garment.

The way direct to garment printing operates is different from traditional screen printing in that you can swiftly print intricate images in numerous colours thanks to the relatively new technology. The print heads of a DTG printer spray CMYK ink and opaque white ink onto the surface of a garment. The ink dries and clings to the fabric by being heated, keeping the print in place.

Direct to Film (DTF) Printing

Direct to film printing is an even newer addition to the garment/textile printing industry. The process is slightly different from DTG in that, as the name implies, the design is not directly printed into the material but instead printed on a film before being transferred using a heat press.

The most notable advantage DTF has over DTG is that it allows you to print on most any type of fabric, such as polyester, nylon, rayon, spandex, cotton, etc. In DTG printing the only reliable material to print on is cotton.

SAi Flexi Software for DTG/DTF Printing

Direct to Film and Direct to Garment printing is one of the fastest-growing segments in our industry. SAi Flexi software for DTF DTG printing makes it easier than ever to diversify your business. A new, expanded feature set in Flexi simplifies artwork design and file preparation for DTF DTG printing, streamlining your workflow and saving you time on each job.

Benefits of SAi Flexi for DTF DTG Printing:

Easy to Use Interface

All DTF DTG tools are conveniently organized under one tab, so you won’t waste time scrolling through menu bars to find what you need. User-friendly dialog boxes allow you to quickly make changes to your artwork files. With Flexi, you spend less time preparing jobs and more time printing.

Versatile White Ink Workflow

White ink is an integral part of DTF DTG printing but can tricky if you don’t have the right software. Flexi gives you different workflow options for generating white layers quickly and easily. Whether you are working with .PNG or .TIFF files that have transparent backgrounds or artwork that contain no white at all, Flexi gives you the tools create transparencies, add masks, and assign white output channels with just a few clicks. For more precise output, you can also use Flexi to create multi-layer artwork with white on a separate layer from spot colours. Flexi gives you the versatility you need to easily handle different types of files without wasting time.

Higher Quality Prints Using Ink Removal

Everyone loves graphic tees, but no one wants a stiff, heavy print on their shirt. If you have a large print, you can give it a softer feel by using Flexi’s special DTF|DTG feature to “Remove Data in Texture Patterns”. This feature allows you to add squares, circles, or dash lines to your pattern. You can adjust the size and spacing of these elements to so less ink is deposited, giving your prints a high-quality, softer texture.

Less Material Waste – Preview Before You Print

Ink and media are expensive, which is why you want to make certain your job is set up correctly before you print. Flexi lets you preview each output channel within the Production Manager interface. Not only can you see how the white layer will print but you can also adjust the white ink density using a simple slider. With these Flexi tools, you can make certain the job is right without wasting ink and media.

Best of all, our textile design and printing software is available on a low-cost monthly subscription plan that easily fits your budget.

About SA International (SAi).

Headquartered in Salt Lake City, Utah, SA International (SAi) is recognised as the global leader in providing software solutions for the sign making, digital printing, textile, and CNC machining industries - from design to production. SAi's Flexi family of software products rank as the world's number one software for sign making and digital printing, outselling all competitors combined. Flexi is found on more wide-format printers than any other software. In addition, the company is one of the leaders in the CNC machining and router markets with its EnRoute CAD/CAM software.

SAi has a large and loyal network of resellers around the world and has over 250,000 customers in more than 150 countries. SAi enjoys strong OEM relationships with industry-leading manufacturers. In addition to its USA headquarters, SAi has offices in Brussels, Belgium, Sao Paulo, Brazil, Shanghai and Hong Kong, China, Pune, India, Tel Aviv, Isreal and Tokyo Japan.

-

Read more ...

In the world of wide-format printing, colour management is not just a technical detail - it’s a cornerstone of quality and consistency. Whether you’re creating vibrant marketing materials, detailed fine art prints, or large-scale signage, ensuring accurate colour representation is critical to maintaining brand integrity and customer satisfaction.

The Challenges Of Maintaining Colour Fidelity

Wide-format printing comes with unique challenges. Variations in media types, ink formulations, and environmental factors can all affect colour output. Without proper management, what looks perfect on a screen might appear dull or inconsistent when printed. For businesses, this can lead to wasted materials, increased costs, and dissatisfied clients.

How ONYX Solutions Address These Challenges

ONYX’s award winning software simplifies colour management with powerful tools designed for precision and consistency:

- ONYX ColorCheck: This feature ensures colour accuracy by verifying output against industry standards. It allows you to detect and correct inconsistencies early, preventing costly reprints.

- Advanced Profiling Tools: ONYX provides robust profiling capabilities that adapt to various media and printer combinations. These tools help create and maintain colour profiles that guarantee accurate reproduction, no matter the material or application.

- Named Colour Replacement: Maintain a library of brand-specific colours to ensure every print adheres to exact branding requirements, essential for corporate identity and marketing campaigns.

Tips For Achieving Optimal Colour Output

- Create Accurate Profiles

Accurate ICC profiles are essential for reliable printing. Use profiling tools to match your printer, ink, and media, ensuring vibrant and consistent results tailored to your workflow. - Calibrate Regularly

Printers and monitors naturally shift over time due to environmental changes and usage. Regular calibration helps maintain accuracy, especially when switching to new substrates or working in different conditions. ONYX Thrive’s ‘ColorCheck’ simplifies this process by creating a baseline swatch to detect variances and ensure consistency. - Use ONYX Tools

ONYX software offers advanced tools like ‘ColorCheck’ and G7 calibration to monitor and adjust output quality. These features make it easy to spot and correct issues early, keeping your prints sharp and consistent. - Understand Your Media

Each substrate has unique properties that affect how it interacts with ink. Testing and fine-tuning your profiles for different media ensures the best results, whether you’re printing on paper, vinyl, or specialty materials.

By combining these strategies with ONYX tools, you’ll maintain flawless colour consistency and deliver standout prints every time. Learn More With ONYX Understanding the nuances of colour management can elevate your printing results from good to exceptional. ONYX Graphics offers specialised color management training courses designed to deepen your expertise and empower your team with the knowledge to handle even the most complex projects. Take control of your colour today and see the difference ONYX can make in your workflow. For more details on training and ONYX solutions, contact PSW for further details

About Onyx Graphics, Inc.

Leading the market since 1989, Onyx Graphics is dedicated to helping customers increase productivity, reduce costs, and gain a competitive edge with superior software solutions for the print industry. Innovative, productive, and delighted customers around the globe help motivate the company to develop and enhance its leading-edge technologies. Global channel partnerships and longstanding relationships with printer manufacturers position Onyx Graphics as a market leader in powerful, reliable, large-format printing workflow and print business software solutions.

-

Read more ...

ONYX Graphics, a leader in RIP software solutions, proudly announces that ONYX 24 has earned full certification for the new HP Latex FS50 and FS60 printer series. This certification from HP ensures that ONYX 24 integrates smoothly with HP’s latest printers, delivering excellent colour control, media management, job processing, and workflow efficiency. For print service providers, this means a streamlined, user-friendly experience that brings out the best in HP’s advanced large-format printing capabilities.

Achieving full certification means that ONYX 24 has passed extensive testing by HP to confirm seamless compatibility and optimised performance with the HP Latex FS50 and FS60. This ensures that ONYX 24 can handle all key functions of these printers—from precise colour management to enhanced workflow efficiencies—so users can rely on consistent, high-quality results.

Chukwuma Peter Eze, Manager of Product Management & Partnerships at ONYX Graphics, emphasided, “This certification highlights our commitment to providing solutions that enhance HP’s newest large-format technology. ONYX 24 is designed to deliver excellent colour accuracy, smooth job management, and expanded white ink options, helping our customers achieve high-quality, efficient print production.”

Key Features of ONYX 24 for HP Latex FS50 and FS60 Printers:

- Enhanced Colour Management: ONYX’s proprietary colour engine offers precise colour control, taking full advantage of the broader colour range provided by the new HP Latex FS series.

- Advanced Media Management: Easily manage different media types with ONYX’s Media Manager, designed for optimal ink usage and media savings across various applications.

- White Ink Capabilities: Leverage advanced white ink options for unique applications, including spot colour overlays and layered printing on transparent media.

- Print & Cut Workflow: ONYX’s contour cutting tools provide an efficient Print & Cut workflow, helping users make the most of their materials while improving finishing quality.

With a focus on sustainability, the HP Latex FS50 and FS60 printers use water-based inks, producing odourless, eco-friendly prints without hazardous air pollutants. ONYX 24 complements this approach, aligning with HP’s commitment to environmentally conscious printing.

About Onyx Graphics, Inc.

Leading the market since 1989, Onyx Graphics is dedicated to helping customers increase productivity, reduce costs, and gain a competitive edge with superior software solutions for the print industry. Innovative, productive, and delighted customers around the globe help motivate the company to develop and enhance its leading-edge technologies. Global channel partnerships and longstanding relationships with printer manufacturers position Onyx Graphics as a market leader in powerful, reliable, large-format printing workflow and print business software solutions.

-

Read more ...

Despite its size, the construction industry has long faced a productivity problem. In 2023, $13 trillion was devoted to construction projects globally, according to McKinsey. By 2040, the industry is predicted to grow by 70%. However, engineers and contractors are already struggling to meet today's project demands

The labour market is fiercely competitive, with shortages in essential roles like engineering and project management. Workforce shortages, retirements, shorter job cycles, and competition for talent have led to a decline in skills and experience. Consequently, construction productivity rose by only 10% between 2000 and 2022, compared to a 50% productivity improvement of the total economy, based on research from McKinsey.

Despite investments in digitalisation, manual processes still dominate workflows, risking human error and creating information siloes. Digitising the construction workflow end-to-end is essential for dramatically reducing the efficiency gap, which could create an estimated $1.6 trillion in additional value and meet half the world’s infrastructure needs.

Introducing HP Build Workspace

Launching today at HP Imagine, HP’s annual product innovation event, HP Build Workspace is a new mobile cloud collaboration platform that brings together all the essential stakeholders on complex building projects, such as urban planning, including architects, designers, contractors, and city planners. By simplifying complexity, improving communication and automating manual processes between the office and field sites, HP Build Workspace reduces construction project lead times from three days to as little as 20 minutes, depending on design complexity.

With seamless integration between digital and physical workflows, the HP Build Workspace platform also features HP Print AI capabilities and enables AEC professionals to:

- Effortlessly capture and organise site observations

- Vectorise their technical designs using AI

- Share floor plans

- Enable real-time feedback

- Automate field reports

Connecting Construction Site Layouts with HP SitePrint 3.0

In July 2024, ACCIONA delivered the design layout for the Alentejo Central Hospital 6x faster than manual methods and over 25,000 sqm of partition walls thanks to HP SitePrint. This is an example of how our connected technologies can significantly boost productivity in complex construction projects. We believe our innovations have the power to address the construction industry's productivity challenges, and our customers are already demonstrating what's possible.

HP Build Workspace combines three key innovations for an integrated, digitized and efficient construction solution:

- HP SitePrint, a robotic solution that prints complex construction site layouts with pinpoint accuracy, increasing productivity up to 10x compared to manual layout techniques (1).

- The print point of the HP SitePrint 3.0 is now up to 30% faster, offering boosted navigation speed and improved robotic capabilities to level up efficiencies in onsite operations (2).

- Additionally, we are working with large HP SitePrint customers on a Proof-of-Concept to check surface flatness, which will be available as a subscription service in selected markets by 2025.

Simplifying Your Printing Experience

The DesignJet T200/T600 Printer series 2025 edition is our most sustainable, intuitive, and optimised large-format printer yet, offering reduced energy consumption and minimising plastic waste by more than 50% with new molded fiber packaging (3). AEC professionals can print digital plans on paper with ease using HP Click Driver for real-print previews from any Windows 11 application. Already in beta in the US and Europe, we intend to scale these AI capabilities to the UK & Ireland soon and roll out worldwide starting next year.

More information on HP Build Workspace and our suite of digital construction tools can be found here.

About HP

HP Inc. (NYSE: HPQ) is a global technology leader and creator of solutions that enable people to bring their ideas to life and connect to the things that matter most. Operating in more than 170 countries, HP delivers a wide range of innovative and sustainable devices, services and subscriptions for personal computing, printing, 3D printing, hybrid work, gaming, and more. For more information, please visit: http://www.hp.com.

1. Based on data from HP SitePrint customers – comparing HP SitePrint’s performance to manual layout techniques used for the same job, including the customer’s estimation (time/resource) for manual layout based on experience working on similar projects. HP’s data typically finds manual layout methods average between 25m2 and 35m2 covered per hour, with a crew of two people. HP SitePrint’s performance averages between 180m2 and 300m2, with one operator. Exact improvement results will vary from project to project and can be influenced by multiple factors, such as the line density or the dimensions of the site.

2. Productivity improvements of up to 30 percent are in comparison to the performance of the previous software version, VP2.0. These results were obtained from conducting internal tests, where SitePrint printed CAD files with average conditions, including element density per area and printed linear density per area, representative of real user plots across various applications. Actual productivity gains may vary depending on specific customer applications and the unique characteristics of each job.

3. The HP DesignJet T200/T600 Printer series 2025 Edition plotter series use EPS-free packaging with molded pulp cushions made from recycled fiber-based material. The plastic reduction is expressed as a percentage of the total packaging plastic weight. The reduction varies depending on the printer model, with at least a 53% reduction in the new 36-inch model and at least a 72% reduction in the new 24-inch model, compared to the previous T200/T600 models.

-

Read more ...

For small businesses, especially print shops, keeping track of finances can be particularly challenging. Owners often juggle multiple roles, from managing day-to-day operations to handling customer service and marketing. Disorganised records, missed invoices, and inaccurate financial tracking can lead to cash flow problems and hinder business growth.

With limited resources, staying on top of financials can become overwhelming.

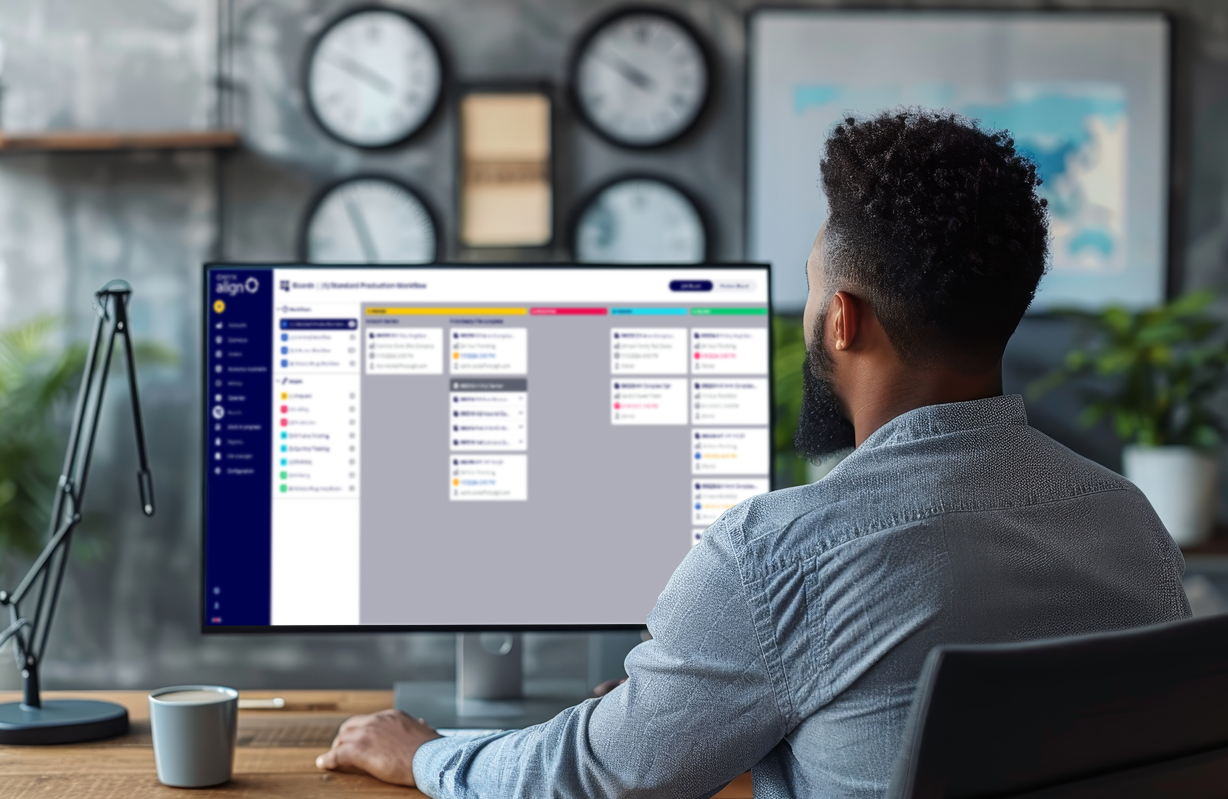

With ONYX Align’s latest update, there’s a clear path to streamlined and efficient financial management. Introducing the new QuickBooks® Online integration - a revolutionary feature for print shops looking to simplify their financial operations.

How Does it Work?

This new feature allows ONYX Align to connect directly to QuickBooks, an online accounting software that assists in payroll, payments, and more.

You can either create a new QuickBooks account to connect to your Align or use a pre-existing QuickBooks account. Either way, this new feature on Align allows you to establish real-time synchronisation between the two accounts to manage estimates, invoices, payments, customers, products, tax rates, payment methods, and payment terms.

Effortless Financial Management

Once you connect your accounts, you can enter any of your financial data into either ONYX Align or QuickBooks, and both accounts will automatically update with the information you input. This makes your financial management effortless and organised, eliminating the need for manual updates and reducing the risk of errors.

Key Benefits of QuickBooks® Online Integration

Direct Connectivity

Establish a seamless link between your ONYX Align and QuickBooks Online accounts for streamlined operations. This direct connection ensures that your financial data is always up-to-date and accurate, providing a clear picture of your print shop’s financial health.

Live Synchronisation

Enjoy real-time updates of customer accounts, jobs, tax rates, payment terms, and methods. With live synchronisation, you can be confident that your financial records are always current, no matter where you enter the data.

Estimate and Invoice Automation

Experience the convenience of automatic creation and real-time status updates of estimates and invoices within QuickBooks Online, all issued directly from ONYX Align. This automation reduces the time spent on administrative tasks, allowing you to focus more on growing your business.

Automated Payment Tracking

Maintain up-to-date records with live synchronisation of all payment activities and invoices, enhancing financial tracking and reporting. This feature ensures that you never miss a payment and always have an accurate view of your financials.

The ONYX Align team is excited to share this seamless integration with QuickBooks Online. This new feature ensures that your print shop has optimised and streamlined operations within your financial management. Say goodbye to the chaos of disorganized records and hello to clarity and efficiency.

Ready to transform your print shop’s financial management?

To try ONYX Align today and experience the benefits of seamless QuickBooks integration contact PSW Paper & Print for an online demonstration.

-

Read more ...

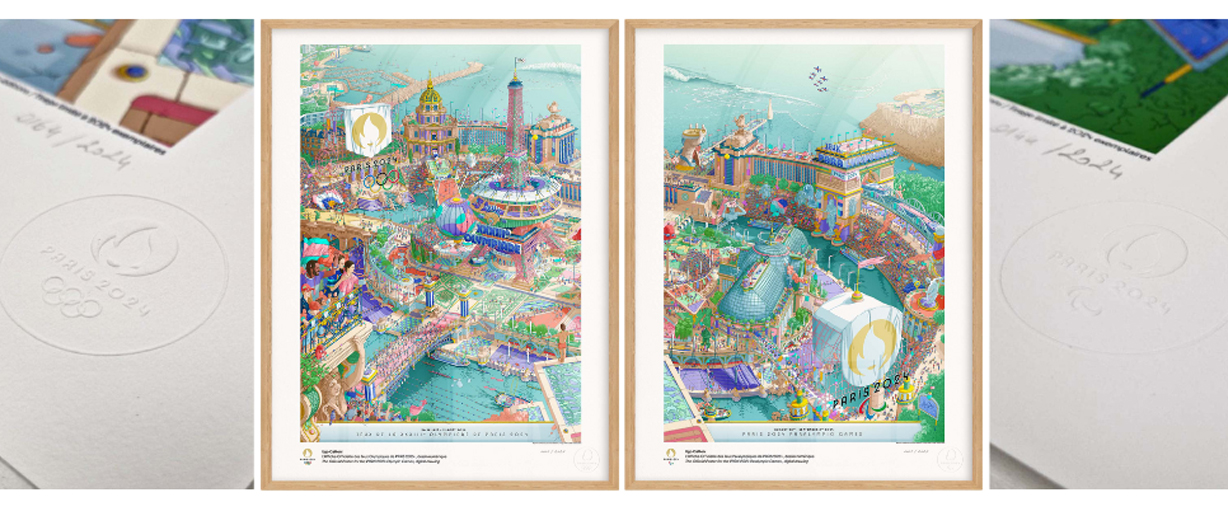

German paper manufacturer Hahnemühle is delighted to announce that its Digital FineArt Hemp paper has been selected by its customer, the French company oneart, official licensee of Paris 2024, to be the exclusive paper for the Paris 2024 Premium Posters. Both the limited edition of the iconic Paris 2024 posters and the ‘Paris 2024 Artistic Programme’ premium posters are printed on Hahnemühle Hemp paper. This premium paper is plant-based, tree-free and vegan echoing both the idea of world-class sporting performance and the sustainable commitments of these Olympics.

Commenting on the choice of Hahnemühle Hemp paper, Stéphane Tisseyre, co-founder of oneart, said: “We were looking for a high-quality paper in order to remain consistent with our commitment to enhancing printed media in line with our motto ‘Exceptional image, exceptional paper’.”

Hahnemühle Hemp Paper – from the award-winning Digital FineArt Collection

Hahnemühle Hemp – from the award-winning Digital FineArt collection – is part of the Natural Line range, developed by the inventor of genuine FineArt papers for inkjet printing. Hahnemühle Hemp uses one of the world’s oldest and most versatile natural fibres to create a sustainable FineArt paper with exceptional haptics and printability.

It consists of 60% hemp fibre from this fast-growing, undemanding and carbon-neutral plant. The remaining 40% of the fibres in Hahnemühle Hemp paper are cotton linters – a by-product of the textile and food industries. The combination of these two plant fibres guarantees certified archival properties and an exceptional colour gamut, key characteristics of genuine FineArt papers.

The base of Hahnemühle Hemp paper is distinguished by its natural white tone, which requires no optical brightener. Its slightly textured surface gives the paper a pleasant silky feel. Combined with the matt premium inkjet coating, this results in a truly innovative and sustainable FineArt paper. Colours, contrasts and details are brilliantly reproduced, while the depth of blacks is conveyed with stunning effect.

Hemp has been an essential part in paper production for centuries, often used for enduring historical documents such as the Gutenberg Bible and the US Declaration of Independence, due to its extremely robust fibres. Hahnemühle has re-invented these fibres to manufacture its genuine FineArt papers as well as Hybrid Hemp paper for commercial printing and publishing.

The official Premium Posters on Hahnemühle Hemp

To commemorate Paris 2024, a limited edition of 2024 prints of the official Premium Posters on Hahnemühle Hemp paper has been released under official licence by oneart in France. Designed by Ugo Gattoni, who spent 2,000 hours creating the diptych of digital masterpieces, the official posters present a colourful and festive vision of sport and the French art of living, highlighting Paris’ most iconic monuments in both daytime and night-time versions. The night-time version of the FineArt 2024 prints sold out well before the start of the Olympic Games.

“These premium posters are special because the Hahnemühle Hemp paper was also the illustrator’s choice. We are constantly striving to remain faithful to the artists’ intentions, and I remember the look and approving smile on Ugo Gattoni’s face when I showed him the first proof – it was love at first sight!” recalls Stéphane Tisseyre, from the printing studio oneart.

Each Olympic medallist received a reproduction of this work of art, housed in an elegant rectangular gold box.

Artistic Posters programme as part of the Paris 2024 Cultural Olympiad

In addition to these official posters, the Paris 2024 organisers offered artists from all over the world a unique platform to express the Olympic and Paralympic values through their various practices, including photography, illustration, painting, drawing and collage. For the first time in history, the Organising Committee has developed the Artistic Posters programme in collaboration with the International Olympic Committee (IOC). These posters are part of the Paris 2024 Cultural Olympiad. They are creating a collective memory of the Games – reflecting on the notions of inclusivity, parity, celebration and innovation at the heart of Paris 2024’s mission. All those premium editions by Adam Janes, Clotilde Jimenez, Elsa & Johanna, Fanny Michaëlis, Gilles Elie, Pierre Seinturier and Stéphanie Lacombe comprise diptychs composed of an Olympic poster and a Paralympic poster – strictly limited to 100 pieces each.

Each limited edition of the official Premium Poster and each Artistic Poster is printed in museum quality with pigment inks on a FineArt inkjet printer on Hahnemühle Hemp paper. They are printed and numbered by hand in the oneart workshop in Fontainebleau bearing an iconic Paris 2024 embossing in the bottom right-hand corner. The three-dimensional embossing attests to its authenticity as an officially licensed product and adorns the velvety Hahnemühle Hemp paper. The unique format of each print is 60x80cm.

Hahnemühle France has collaborated with the printing studio in France for all limited editions prints. All Premium Poster can be viewed and purchased here: oneart.fr/en.

About Hahnemühle:

Hahnemühle is considered the inventor of Premium Digital FineArt papers for inkjet printing. As a pioneer, the oldest German artist paper manufactory has been refining its artist papers for photography and art reproductions and in 2022 Hahnemühle celebrated the 25th anniversary of its Digital FineArt collection. Hahnemühle is an international premium manufacturer of exquisite papers and has stood for quality, innovation and expertise in crafting since its founding in 1584. In 2024, the company celebrates an incredible 440 years of uninterrupted paper production at Hahnemühle’s headquarters in southern Lower Saxony.

The Digital Fine Art Collection is a comprehensive assortment of high-quality, unique FineArt inkjet papers created for customers who are looking for something special and want to get the best out of their images. Achieving outstanding printing results and a high age resistance of over 100 years, Hahnemühle FineArt inkjet papers meet the highest standards for fine art applications and are perfect for long-term exhibitions, art collections and special editions.

The Hahnemühle Digital FineArt Collection offers more than 20 different papers, while the Hahnemühle Photo Range now includes 8 media. Among them is the world’s first PF-free, fully recyclable photo paper with a bio-based barrier layer.

All paper grades are produced according to old recipes from high-quality cotton fibres, cellulose or fast-growing plant fibres with advantages in CO2 balance, durability and quality benefits utilising pure spring water from Hahnemühle´s own artesian wells.

Hahnemühle has a worldwide reputation as a ‘Brand of the Century’ among photographers, artists, museums, galleries and collectors. Products are available in more than 130 countries worldwide.

The company is headquartered in Dassel, Southern Lower Saxony; with offices in the United Kingdom, France, USA, Singapore and China.

For further information on the brand, history and environmental responsibilities visit www.hahnemuehle.com

-

Read more ...

Onyx Graphics Inc. is excited to introduce ONYX 24, the latest in its line of RIP (Raster Image Processor) software, designed to revolutionise wide format print workflows. This new version boasts intuitive tools that automate processes and ensure efficient colour management, promising to enhance productivity across the board.

In today’s fast-paced print industry, businesses are increasingly reliant on streamlined workflows to meet growing demands. ONYX 24 addresses these challenges head-on with cutting-edge automation controls that minimise manual intervention, accelerate production timelines, and significantly reduce potential errors. This means smoother operations and more consistent output quality, essential for maintaining competitiveness in the market.

Understanding RIP Software

RIP software is pivotal for transforming digital images into high-resolution prints. It optimises images by adjusting colour balance, brightness, and contrast before translating them into a format compatible with the printer. This software is indispensable for printing companies and businesses utilising wide format printers, ensuring that large-scale prints retain their intended quality and clarity.

Why Upgrade to ONYX 24?

ONYX 24 is tailored to meet the evolving needs of modern print environments. It’s not just about speed and efficiency; it’s also about usability and sustainability. Key features of ONYX 24 include:

- Multilayer Printing: Seamlessly stack and adjust multiple images for applications like posters, fine art, and signage, allowing for creative flexibility and precise control.

- Named Colour Replacement: Maintain a library of brand-specific colours to ensure consistency across all prints. This feature is invaluable for marketing materials, package designs, and corporate branding efforts. Save colours and settings from images as filters and create stunning multi-layer prints with accurate previews using enhanced spot layer generation.

- Label Placement: Easily add labels above, below, or on images, and place data and QR codes anywhere. This feature is designed to reduce mistakes with artist-friendly options.

- Nest Preview and UI Enhancements: Customise and zoom in on the nest preview dialog box to easily visualise and choose specific layers before printing.

- Nix Spectro 2/L Colour Device: Enhance color accuracy with the Nix Spectrophotometer, a compact device that connects via Bluetooth. It offers a range of colour profiles and references, keeping your prints up to date with the latest industry standards.

- Archive: Safeguard your data with ONYX Archives. Securely store and access previous job and client files, preventing data loss with guaranteed access.

- Best Fit and Allow Rotation 2.0: The new algorithm optimises image placement for all resolutions, reducing media waste while ensuring quality and saving money.

- Fotoba Enhancements: Improved cutting workflow includes vertical line notch placement and barcode offsets, perfecting print details before cutting.

- New Mimaki XY Slitter Placement: Connect to ONYX 24 for flexible print-and-cut options, with compatibility for cutter marks on other printers.

- Flood Fill Behind Marks: Improve mark visibility by flooding the area around images with a customisable spot colour on dark, transparent or reflective media, ideal for all cutter types.

- Background Colour Under Marks: use any ink colour to create a footprint underneath each mark specific to your cutter, optimising mark visibility while also saving ink and space.

ONYX recognises the critical role of reliable RIP software in achieving superior print results. ONYX 24 seamlessly integrates into existing workflows, providing effortless automation and precise colour management tools that empower users to deliver exceptional prints consistently.

As Onyx Graphics prepares for the launch of ONYX 24, we invite you to stay tuned for updates as we discover how these advanced features can transform your printing experience, making it simpler, faster, and more sustainable than ever before.

-

Read more ...

Diversifying into vehicle wrapping can be a lucrative decision for growing print businesses, no matter where you’re at in your large format journey. Recent advances in print technology have made wrapping easier than ever before. With durable water-based inks, intelligent media and, more precise large-format printers all available, there’s never been a better time to get involved.

Market growth

Vehicle wrapping is seeing an especially sharp rise, with the automotive wrap film market expected to grow 22.4% from 2021 to 2028. 1 The broader signage industry also remains resilient, as it’s a cost-effective solution for almost any business sector. This is all thanks to wider growth in the online and delivery sectors: E-Commerce is expected to grow by 16% in 2022, 2 and this means more demand for branded vehicles on the road. With 69% of customers finding out-of-home advertising more trustworthy than digital advertising, 3 it’s time to take advantage of these new opportunities and get results.

To get you up to speed with the basics including materials, technologies, and practical applications we’ve pulled together some of the most useful hints and tips into our short, handy guide.

Tip 1: Select the right media for the job

We’re going to focus on wrapping films in this section, as it’s a durable solution for vehicle wraps, but these principles apply to all media types. Cast vinyls are likely your go-to substrate for car wraps: they’re easy to contour, stretch, and cut, but this flexibility comes at a higher cost. If you’re printing to flatter signage surfaces and want to save some money, calendared vinyl is the way to go.

When there are so many options, you need a versatile print solution that can keep up. HP Latex is fully compatible with substrates from leading brands such as 3M and Avery Dennison. With HP, you can find a solution that fits your application needs and current equipment. These can all be found on HP Media Solutions Locator, giving you access to perfect media for your printer or application. Don’t forget to consider warranties for peace of mind. HP Latex printers are eligible for six year 3M MCS and Avery ICS warranties4 for vehicle graphics–helping you print with confidence.

Tip 2: Measure and measure again

A top tip for ensuring a successful sign or vehicle wrap, is ensuring that you have the measurements, images, and specifics of the surface, item, building, or vehicle you are designing for. For vehicles, especially for full wraps, you’ll need the latest vehicle templates, which you can find online. This will ensure your design fits properly, without distortion or slicing the image into pieces.

Tip 3: Design with the end-installation in mind

Less is sometimes more. The human eye can take in seven items at a time, so when designing it’s important not to try and pack in too much information.5 Equally, colour and font can help get your message across–but don’t use too many.

For signage, perspective and distance is key. Choose your lettering size carefully to optimise visibility according to the reading distance. As a rule of thumb, for every 3 meters of viewing distance away from your sign, you should increase the letter height by 2.5 centimeters. 6 HP Latex helps you print sharp images and text for easier eligibility. With a resolution of up to 1,200 DPI, 7 you can print clear text all the way down to 4-point font sizes.

Tip 4: Choose white ink–for prints that pop!

Printing with white ink can drive up your gross margins by up to 30% by adding depth and vibrance to your images–especially on transparent and coloured substrates.8 It can also make previously challenging (or even impossible) projects easier, saving time on additional processes and materials.

HP Latex White Ink gives you all the benefits of white without the complexity. HP Latex printers with white ink, such as the HP Latex 700W, 800W, or HP Latex R-series, feature automatic recirculation to prevent clogging. Additionally, they’re built with an offline rotation chamber for white printhead storage, to minimise waste between white ink jobs.

Tip 5: Select the right print profile

Let’s say you have the design ready, and you’ve chosen the ideal material for the task. Next, it’s important to deliver a sharp, high-quality image for your sign or vehicle wrap. HP offers a wide range of tested, approved and certified ICC print profiles for HP Latex printers. These profiles give your machine specific instructions on how much ink to lay down for the optimum result. This ensures images are not subject to colour shifts, over-saturation, insufficient ink coverage, edge curling or, drying problems.

A lot of print shops don’t follow this important step and use one generic profile for all their media, resulting in images that appear dull or just not quite right. So, by making sure to select the right print profile, you’ll definitely win on quality.

Since you’ll most likely laminate your vehicle wrapping prints, remember to disable the overcoat when selecting your profile.

Don’t forget–the latest generation of HP Latex also gives you a 10% higher colour gamut, giving you vibrant and accurate colors on any substrate.9Tip 6: Move into lamination

As your vinyl or film will be exposed to the elements, you need to select one that’s suitable for lamination to prevent scratches or water from dislodging it from the surface.

Tip 7: Eliminate the need to de-gas

By choosing HP Latex technology, you can remove the need to de-gas your vinyl prints before you install them. HP Latex prints are dry straight from the printer, ready to be laminated or installed immediately after leaving the print tray. This cuts out an entire step from your vinyl printing workflow, saving you time, and freeing up your resources for other tasks. A great way to boost your productivity and improve your bottom line.

Tip 8: Start your installation squeaky clean

The most time-consuming part of most signage or vehicle wrap installations is the preparation stage. For new signage installations, this may involve removing old graphics and adhesive, then washing with water and detergent to ensure a grease-free dry surface. When preparing for a vehicle wrap it’s essential to clean every inch of the surface as well as under trims and cracks to make sure they are 100% dirt-free. You should use a suitable solution to remove any wax, before wiping the vehicle with alcohol to remove any residue. All cleaning must be completed the day before to ensure the vehicle is completely dry before installation. Understandably this is often the least preferred part of wrapping a car and is sometimes neglected, but this is at the peril of long-term wrap durability as the slightest dirt left behind could result in the vinyl’s adhesive failing. So, to be sure of success, make sure your vehicle is always squeaky clean.

Tip 9: Apply graphics with ease

The installation of a car wrap undoubtedly requires skill and practice. But the real key to success is post-heating. After the wrap is installed, you should apply a heat gun to the vinyl at 85-95 degrees Celsius, especially where there are deep recesses or contours. This will ensure that the vinyl will retain its memory and remove the risk of it ‘popping’ out.

If you are wrapping in colder weather, keep the car inside until the next day. This will allow the vehicle and vinyl to cool down gradually to minimize the risk of lifting.

With the HP Latex 700 and 800 printers, you can achieve 30% better adhesion to laminate, 10 making it easier than ever to get smooth, long-lasting fits. What’s more, HP Latex Inks are very flexible. Discover ink elongations up to 30% without losing quality.11What are you waiting for?

Signage and car wrapping undoubtedly offer a range of exciting possibilities for entrepreneurial print businesses to explore. There are certainly some tricks of the trade to learn upfront, but once proficient, you’ll be able to offer a wide portfolio of services that will ensure your customers will never need to go elsewhere.

Remember, you’re not alone on the journey. Printer manufacturers and media vendors are always on hand to help, and you’ll find online tutorials and videos to help with any questions along the way.Footnotes

1. Grand View Research, Automotive Wrap Films Market Size Report 2021-2028, https://www.grandviewresearch.com/industry-analysis/automotive-wrap-film-market

2. Insider Intelligence, Ecommerce Industry Statistics, https://www.insiderintelligence.com/insights/ecommerce-industry-statistics/

3. Statista, 2016 https://www.statista.com/topics/5771/out-of-home-advertising-uk/#topicHeader__wrapper

4. Warranty coverage varies by region, please see graphics.averydennison.com and 3Mgraphics.com for information about what is offered in your country. Some warranty limitations may apply.

5. Simply Psychology, Short-Term Memory: Facts, Types, Duration, and Capacity, https://www.simplypsychology.org/short-term-memory.html

6. Signs.com, Signage 101 – Letter Height Visibility, https://www.signs.com/blog/signage-101-letter-height-visibility/.

7. HP Latex 800 print resolution: up to 1,200 DPI. See the spec sheet for more info: https://h20195.www2.hp.com/v2/GetDocument.aspx?docname=c06990640

8. Based on research conducted by Keypoint Intelligence July 2020 and commissioned by HP, across over 100 print service providers across the U.S., Europe, and India

9. On HP Latex 700 and 800 printers, when compared with same ink density in HP Latex 365/5x0 printers. HP Latex 700/800 printers provide lower color distance to some Pantone* (average visual colour distance 1.99 dE vs 3.34dE): Blue (Pantone 289C): 1.3dE vs 3dE, Red (Pantone 201C): 0.49dE vs 3.8dE, Orange (Pantone 153C): 1.6dE vs 3dE. *Measured Xrite i1Pro 2, dE calculated based on the CIEDE2000 standard L500 (10p: 151 sqft/h 110% saturation) vs. L700/800 (8p: 183-215 sqft/h 120% saturation)

10. Compared to HP Latex 365/5x0 series printers.

11. HP Latex 365/5x0 and 700/800 Printers inks show similar ink flexibility performance. We can support ink elongations up to 30% (2dE criteria). In case of HP Latex 700/800 printers, white ink has similar flexibility as the other colours.