Monthly Archives: April 2023

-

Read more ...

Plotters and printers may seem similar at first sight as both produce replication artwork. The latest plotters and printers support memory cards, digital cameras, and scanners. And they’re both considered peripheral output devices, which means several computers can connect to them.

The key difference between them is that plotters deliver a much higher resolution in a format that is similar to a vector graphic (an image created with very fine lines). This means they’re ideal for producing documents that are reliable, accurate, and error-free. These documents are typically specialized high-quality drawings such as blueprints, circuit diagrams, maps, hatch patterns, etc. And for this reason, plotters are more suitable for use within architectural, engineering, and construction (AEC) industries.

A traditional printer, on the other hand, uses toner to print multiple dots of ink, or pixels, usually onto paper, which is not as clear or precise as a plotter. Generic printers also print up to 11x17, while some plotters can print to up A0, which is nearly three times larger. The size limitations of printers can cause some AEC firms to lose out on larger jobs.

Other important differences

Images produced using large format plotters can be enlarged without losing clarity or resolution, unlike generic printers that print blurry or pixelated images.

Printers can only print a single line at a time, while plotters have movable printheads that can easily draw continuous lines at the same time. Printers, in turn, print hard copies more quickly than plotters and at a lower cost.

Large format plotters can read files in DWG, CDR, AI, and other vector formats. Its software includes Adobe Illustrator, Corel, Flex, and CAD. Printers can read BMP, PDF, and JPG TIFF formats, and its software includes Photoshop and other image-editing programs.

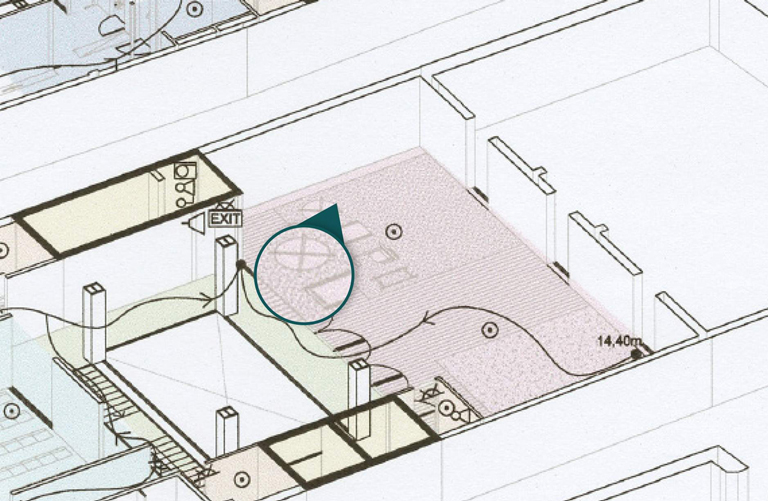

Scenario 1: Printing colour blueprints with many fine and bold lines

Colour blueprints with numerous fine and bold lines are clearly superior when printed on an 11x17 plotter that is built for these kinds of tasks.

This printout was created using the HP DesignJet T200 Plotter series, which is a unique large format plotter with print capabilities. When placed side by side with the output of a generic large format printer, it’s clear which delivers the better print quality.

The HP DesignJet T200 Plotter series is also capable of printing up to A1 - and provides fast, one-click printing of multiple files. The A3/B automatic sheet feeder accessory lets you print multi-size large format workflows without changing media input. Plus this series uses up to 95% less ink for routine maintenance.

The HP DesignJet T200 Plotter series is also one of the most sustainable large format plotters in the world, reducing carbon emissions with up to 30% recycled plastic.

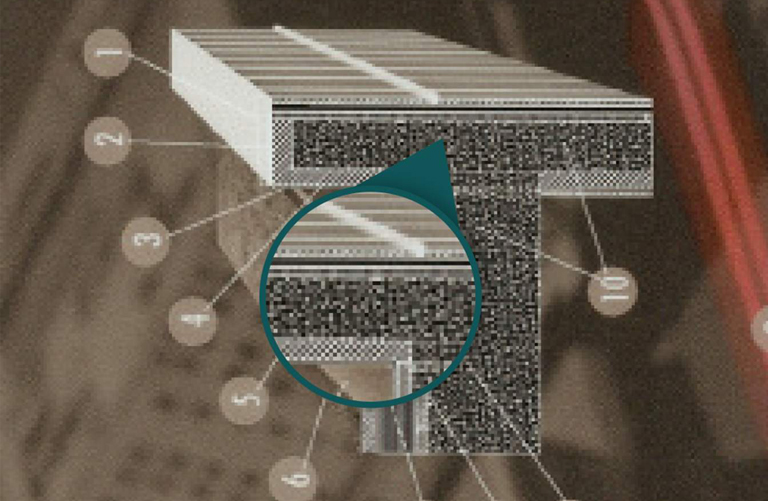

Scenario 2: Printing hatch patterns

HP’s large format printer plotters produce more accurate replication of hatch patterns and texture while generic large format printers will lose details.

The hatch pattern above was produced using the HP DesignJet T650 Plotter series. This large format printer plotter is able to print multi-size A3/B and A0/E projects automatically without having to switch the media source manually. It uses up to 95% less ink for routine maintenance than competitors and prints up to 100 additional A1/D pages per month. It also increases user productivity by printing up to two times faster, while HP Bright Office Inks plot with up to 31% more line accuracy and up to 65% more gamut. Its ability to print up to A0 size means it can meet the printing requirements of AEC companies producing larger prints and blueprints.

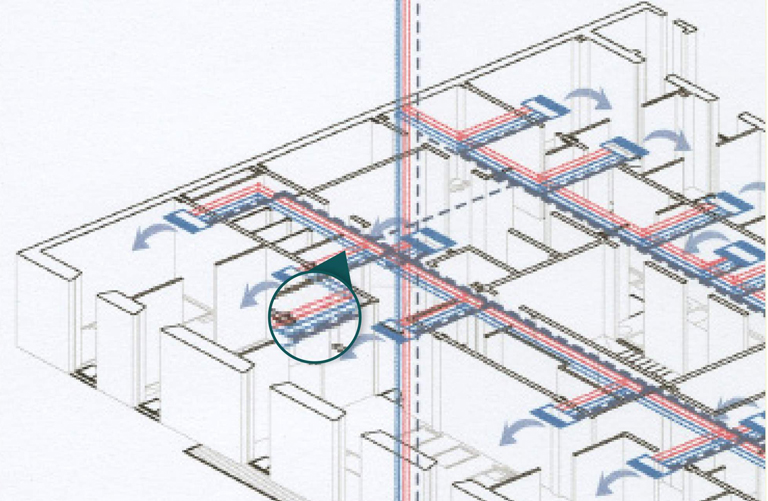

Scenario 3: Printing diagrams with multiple colours

As a large format printer plotter is designed for AEC purposes, it produces prints with brighter colours compared to the dull, grainy output of generic large format printers.

This output comes from the HP DesignJet T2600 Printer series. Because it can print five colors with greyscale, it delivers the highest accuracy and displays the finest details using the unique Adobe PDF Print Engine. It also easily digitizes projects with automatic scanning, user-centric quicksets, and post-editing capabilities. It empowers your workforce by allowing users to work quickly and collaboratively with easy access to shared folders for printing and scanning.

The two-in-one choice

Besides giving your office the capabilities of a large format plotter AND printer, the portfolio of 11x17 printer plotters has many other appealing features and attributes. They are among the world’s smallest yet fastest large format printer plotters. They fit your office, the way you work, and your budget. And they’re also incredibly quiet -with up to 87% less noise using the HP DesignJet T2600.

-

Read more ...

Social responsibility is a hot topic for businesses across the board. This is particularly true for the print industry, with one recent study from HP and C Space finding that 85% of print businesses that operate Latex large format printers are demanding sustainable products and practices.1

Companies of all sizes need to respond quickly, and the important thing is to see it as both a socially responsible endeavour and an economic opportunity. One that can enable print businesses to lower their costs, streamline services through more efficient, circular processes and win new business by delivering sustainable services to even the most eco-conscious customers.

Why the industry needs to pursue social responsibility

Research suggests that print businesses are keen to become more sustainable, with a study by Widthwise2 showing that in 2020 three quarters has achieved environmental accreditations, with 9% working on getting them, In addition, the major environmental focus for that year was to measure and reduce the carbon footprint for almost half of PSPs, with 16% planning to reduce or recycle in-house waste. Mean while, there is an urgent and growing need to find alternatives to materials such as PVC, whose manufacture and disposal are recognised as dangerous to the environment due to the release of harmful chemicals. Along with big brands, the print industry is responding, with many suppliers developing more eco-conscious media.

Making social responsibility profitable for your print business

While the print industry is clearly making significant inroads into sustainable practices, it’s still at the foothills when it comes to making social responsibility an economic advantage to the business. However, there are many ways that print businesses, both large and small, can make environmental practices work for them financially. Among these are reducing energy consumption by using more efficient printers. Or adopting printers that use recycled or recyclable materials and less packaging, and reflect this in their cost. Improving in-house energy generation through solar power may also be worth pursuing. Or using dashboard tools to closely measure metrics in order to identify and drive efficiencies and track ROI so the business can make more informed buying decisions. In addition, developing environmentally friendly print services for eco-conscious customers can be a competitive differentiator. For example, printing facilities can have their sustainability practices certified through accreditations such as the US-based Sustainable Green Printing Partnership (SGP).3

Why it's imperative to improve employee safety

Employee safety is, and should be, an important aspect of social responsibility and something that businesses should make every effort to de-risk. The most common types of print industry accidents are due to manual handling (27%), slips and trips (22%), and machinery (22%). So, as well as making print services more environmentally friendly, PSPs also need to improve employee safety by reducing risk, providing training, and avoiding manual handling where possible in favour of digital and mechanical automation. Where solvents and UV can irritate the skin, leading to dermatitis, businesses should investigate less harmful chemicals and water-based inks, which fundamentally provide healthier print production without trading off performance. Governments have put strict guidelines in place for the printing industry. These regulations are formulated to safeguard the lawful rights and interests of printing operators as well as social and public interests. Furthermore, labour organisations and councils across the globe ensure that the legislation passed for worker safety isn’t overlooked. And by safeguarding employees and developing a protective and healthy environment, PSPs will increase staff safety, satisfaction, and retention, which will ultimately benefit the business as a whole.

Rising to the challenge of change

Print businesses are under pressure to change. But they have proven themselves resilient over recent years: able to adapt to the market, transform digitally, and adopt sustainable practices. The next few years will be critical in continuing the good work that’s already been done in order to create a bright future anchored in environmental, societal, and economic sustainability.