Flatbed Cutters

-

Read more ...

Summa nv, a leading company of high-end cutting plotters and finishing systems, has released a new version of their GoProduce software, GoProduce Flatbed Edition 3.0. This software is explicitly tailored to Summa’s flatbed cutter range, the F Series. As a result, the in-house developed software ensures optimal utilisation of the flatbed cutters and efficiency in customers' production processes.

GoProduce Flatbed Edition

GoProduce was originally released in 2019, as the first software module within Summa’s GoSuite platform. This was followed by a major upgrade to version 2.0 in 2020. Summa always strives to deliver innovative and cutting-edge solutions, so the major upgrade was done to stay up-to-date with the latest technologies. Out of the same aspiration, GoProduce Flatbed Edition 3.0 is born. The specification ‘Flatbed Edition’ has now been added to the software name to make a clear distinction in the software available, as Summa also has production software for their L Series laser cutters called GoProduce Laser Edition.

The software comes with every new F Series and is easy to install. With its intuitive interface and easy navigation, the software is user-friendly and users quickly find their way around. For users who want to get the most out of their cutter and workflow, a Pro Pack is available that unlocks additional features such as Barcode functionality, Hot folder support and Twin X workflow.

General great things about GoProduce:

- Material manager: Library of materials and their optimised settings. There is already a whole lot of them included but you can also add new ones manually.

- Action sets: there are standard action sets or you can custom make them, perfect to optimise the workflow for your way of working.

- Backside cutting: it’s possible to cut the unprinted backside of the material, perfect for cutting packages, as that way the tool does not damage the design.

- Sorting: Optimises the cutting path, making the machine more efficient and makes your output faster.

- Barcode functionality Pro Pack: The barcode functionality reads the printed barcode and automatically identifies the job to obtain the necessary cutting data from the computer.

More Powerful, More Connected, More Enhanced

The new GoProduce Flatbed Edition 3.0 is now available, and it has some great new features:

- Powerful 64-bit software: Not only does the software run faster, but there is now more working memory, making it operate more efficiently.

- Connected media handling: It integrates the flatbed cutter smoothly with peripherals to create an efficient automated workflow, using our GoConnect software integration.

- New predefined action sets for automatic feeder support.

- New logging features for better support.

The V3 software is optimised for routing jobs. It comes with new routing capabilities that are perfect for cutting out shapes more precisely. They maximise productivity when processing wood, acrylics, and plastics. The features supporting this are:

- Automatic detection of drill hole placeholders.

- Lead-in or lead-out for the milling path: It can now automatically start and end outside of the shape. There are two possibilities to do this using either a perpendicular lead-in or corner lead-in.

Empower Your Machine Precision

Randi Kerkaert, Product Manager at Summa, reflects on the importance of the upgrade for our customers: “I'm excited to see how this major software release will take our customers' production processes to the next level. We’re not just updating features; each major upgrade enhances the way our users interact with their F Series flatbed cutters and helps to maximise the productivity of their equipment. With GoProduce Flatbed Edition 3.0, we're once again raising the bar for what users can achieve with our software."

The GoProduce Flatbed Edition 3.0 software is available with every new F Series and as a paid upgrade for existing users. A 30-day trial allows existing F Series users to discover the new features in the software: https://www.summa.com/en/support/software-firmware/

-

Read more ...

Enhanced performance, quicker, more productive, more efficient, better outcome and facilitating the operator’s life, are only a few of the many benefits you can achieve with the upgrade possibilities on an F Series flatbed cutter from Summa.

Did you know already that our F Series flatbed cutters can be enhanced with a range of upgrades and add-ons according to the pace of your company’s growth, aspirations and goals? We gladly point them out for you below.

1400W ROUTER MODULE

The 1400W router module – which can be purchased at an entry-level price - offers an attractive performance increase with improved output quality over the standard router. The router is capable of handling the most used solid boards in the Graphic Industry. It is suitable for milling, contour cutting, polishing and engraving. (Available add-on for all F Series models)

F-PERFORMANCE MODE

The F-Performance mode ensures an increase of up to 40% of the F Series’ performance. Advantages include faster up, down and turning movements of the cutting head, which will be most remarkable when using the Kiss-cut tool. Also, feeding material will happen significantly faster. The job will be finished practically twice as fast without compromising an inch on quality. (Available add-on for all F Series models)

Note: The F-Performance mode is available as free unlock on new machines and as payable unlock on older F Series models, built before 2018.

CONVEYOR EXTENSION

Thanks to the conveyor extension, the F1612 makes light work of cut designs, that are much larger than their actual cutting area. Once the first part of the job is completed, the conveyor feeds the cut material to the extended front where it can be removed easily and safely, while the machine is cutting the next part. This minimizes downtime considerably. (Available add-on for the F1612 model)

Note: All existing F1612 units in the field can be upgraded with this option.

BASKET

The basket is a handy accessory to reduce the media handling time, thus optimizing your workflow. The F1612 can automatically process several feet of material while the basket is capturing the cut-out vinyl and/or waste material. Rely on an efficient cutting workflow and a clean work environment. (Available add-on for the F1612 model)

EXTENSION TABLES

The sturdy, foldable Extension Tables can be placed in front and at the back of an F1612. They are adjustable to set the correct height. This way, board material longer than the F1612 working area can still be processed. With the extension tables, you can use the continuous sheet feed feature, which enables the user to load and unload material while cutting. The feature helps to avoid idle periods during the processing of material and thus adds significant value to the overall workflow. (Available add-on for the F1612 model)

ROLL-UP SYSTEM

When kiss-cutting, the roll-up system winds the material back on a roll after it has been cut. This allows the F1612 to work unattended while keeping the work area neat and clean. When cutting through, a workflow can be set up in combination with the basket or extension table. The roll-up takes care of the waste matrix while the operator collects the cutout material. The winding roll is also easily accessible for trolleys or other tools to handle heavy rolls. (Available add-on for the F1612 model)

HEAVY-DUTY ROLL SUPPORT (HDRS)

The Heavy-Duty Roll Support can be used on our wide format flatbed sizes to allow a straight and effortless throughput of heavy print rolls before cutting the material. Especially for the processing of heavy banner material, non-stretchable wide textile rolls and lightly stretchable materials, the HDRS will prove its worth. It will even allow the processing of rolls up to 200 kg with ease. (Available for F1832, F3220 and F3232 models)

BARCODE WORKFLOW WITH THE GOPRODUCE PRO PACK

The Summa barcode workflow on the F Series generates an automatic process of identifying and opening cut files to start cutting an entire roll without user intervention. This optional feature will increase your productivity and enhance flexibility substantially whilst freeing up time for the operator to attend to other assignments.

Note: the automated barcode workflow, based on the F Series’ built-in camera system, is included with the Summa GoProduce Pro Pack (one-time purchase).

For SummaFlex users: possibility to upgrade to GoProduce Flatbed Edition software

For flatbed machines shipped as of March 1, 2019, the GoProduce Flatbed Edition Software is included. But if you happen to have an older F Series unit, you may be still working with the SummaFlex software. Now, if you want to keep up with the latest features, and updates and ensure you can use the latest techniques on your F Series equipment, we do recommend upgrading your software to the GoProduce Flatbed Edition software. -

Read more ...

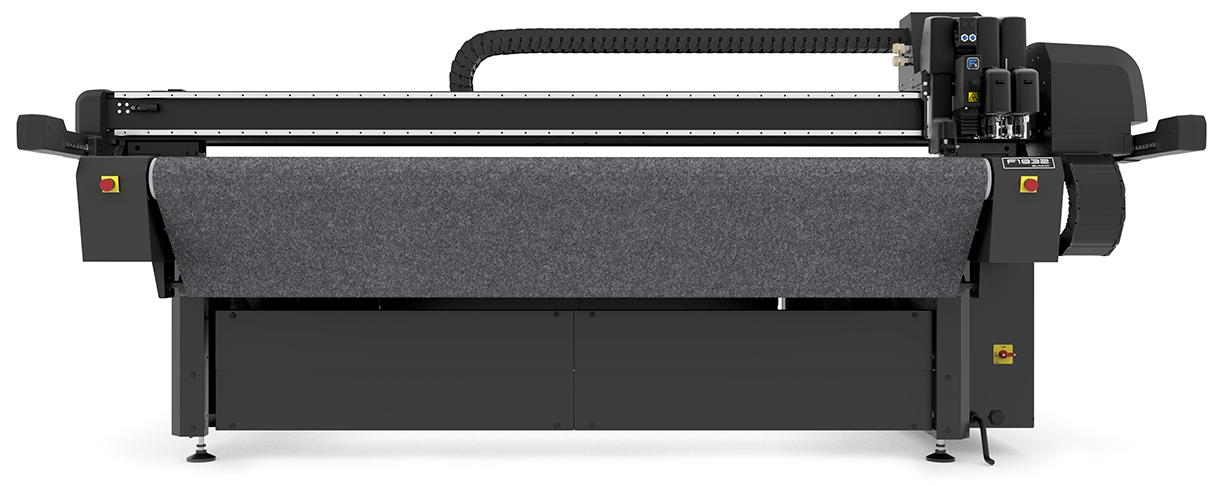

Summa is proud to announce a range of improvements on its renowned F Series flatbed cutters. The flatbed cutters have been one of the most versatile products in Summa's range for many years. By improving the range, Summa brings its standard to the next level when it comes to quality, reliability and productivity. Summa is excited to present a new size of flatbed cutter, an enhanced safety system and its GoProduce software. These updates will contribute to an even better alignment of the F Series to realize present and future customer projects.

Meet the F1432: New size, new opportunities

The new F1432 flatbed cutter, available in December, accommodates users in the sense that it opens the possibility to process popular 137 cm/54" roll widths more efficiently. Moreover, the increased working length gives a sufficient margin to easily cut 3m/10ft jobs. For many businesses, this size represents the ideal interim solution between the F1612 and F1832 size.

Elice van Es, Summa’s Marketing and Communication Manager explains: “We are seeing a great fit in the market for our new F1432 flatbed cutter. The F Series flatbed cutters are appreciated for their versatility and performance and this new size underlines our philosophy. Thanks to the great number of applications that can be cut, we are convinced this flatbed cutter will benefit many customers’ businesses.”

Integrated Safety System for a safe and accessible work environment

Another major update on the F Series is the integration of a Safety System on all F Series models. The new system complies to worldwide health and safety requirements and thus represents Summa’s new standard in making the F Series operator’s work environment safer than ever. It features multiple sensors that can quickly detect human movement close to the machine. With the system’s convenient location on the top beam, the flatbed can now be accessed easily and safely. This in contrast to the former safety poles that are no longer needed.

Automatic Depth Control on the left side

The ADC feature on the F Series automatically sets the knife depth and the orientation of the knife/tool. The tip of the knife/tool is measured accurately and the down position of the tool is set to the flatbed’s level, guaranteeing a flawless cut at all times. This feature was already included for the right slots of the flatbed’s cutting head and proved its practicality. Now, Summa also makes ADC left standard available for all F Series models, which is the next step in production and operation efficiency.

GoProduce 2.0 software to perfectly match the F Series hardware

Along with the F Series enhancements related to hardware, it is the software that enables the operator to make good use of the machine’s functionalities. Therefore, Summa continues to develop its GoProduce software and now presents GoProduce 2.0. It is standard delivered with each new F Series and offers various new functionalities. While the standard integrated software includes many functionalities already, new is the availability of a Pro Pack. This Pro Pack is a one-time purchase and offers even more functionality to the F Series operator who wants to maximise his cutting workflow possibilities. For more information visit www.summa.com.

Elice van Es concludes: “Constantly listening to the market and analysing the needs of our customers is an important basis for us in the development of new products. We also believe that hardware and software should always be in harmony enabling us to offer users a complete solution and deliver true ease of use. Ready to create innovative and striking applications and tap into new markets. This is exactly what makes the Summa F Series so unique. The Series grows at the customer’s pace and needs alongside with evolutions in the industry.”

About Summa

Every day, for more the 3 decades, Summa delivers the world's highest-quality vinyl and contour cutter. finishing flatbeds and laser cutters without compromise. Summa provides cutting edge solutions for the printing, signage, display, apparel and packaging industries. Summa's global headquarters is located in Gistel, Belgium.

-

Read more ...

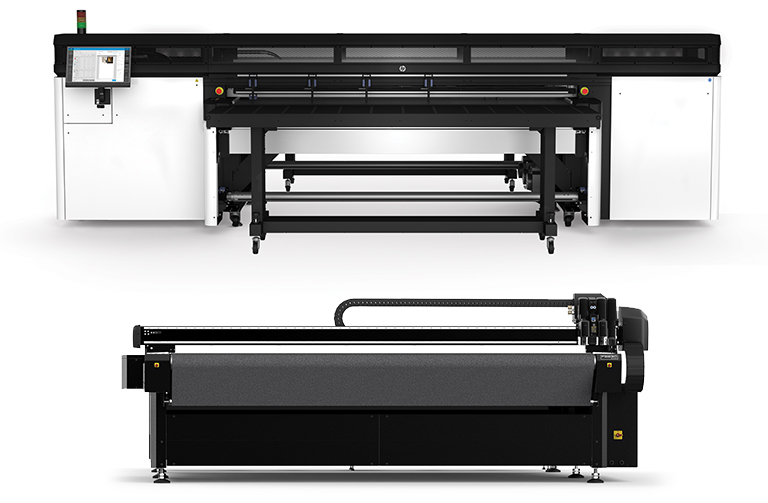

Integrated workflows with print and cut solutions are enabling businesses to shorten lead times and offer a wider range of applications than ever before. Therefore, Summa is proud to announce that HP has validated Summa’s F Series flatbed cutters for the HP Latex R Printer Series. The printers and cutters complement each other perfectly, bringing customer workflows to the next level.

While obtaining stunning colours on rigid, or even flexible materials with the HP Latex R Printer Series, the finishing with Summa’s F Series precision cutters delivers the same level of quality. This enables businesses to combine the choice of material, design, colour results and cutting quality into excellent end products. HP states that the aim of the HP and Summa Partnership is to enhance the value proposition and competitive advantage of HP Latex and Summa with solutions for the E2E printing environment beyond the printer.

Summa’s Executive Director, Wim Maes: “This year, Summa accomplished its goal to improve the synergy with the large format digital printer market, by launching two large-format flatbeds matching the 3.2 m (10’ 5”) working width of printers perfectly. In combination with Summa’s GoProduce software, the F Series ensures the highest versatility to process all kinds of material and offer numerous high-end solutions to the sign making, textile, and digital print industries. Even more so, with the HP Partnership and validation for the F Series with the HP Latex R Printer Series, this pursuit of excellent synergy between printers and cutters has reached new heights.”

Meet short deadlines

Both the printer and the cutter are made to deliver the highest quality with optimum lead times. But in order to make a significant difference in the time needed to process the order, it is indispensable for both operations to be perfectly coordinated. This is exactly why collaborations, such as this print and cut solution, are so powerful to optimise workflows, save valuable time and deliver products that meet the needs of the customer in time.

Workflow versatility to the next level

A well-integrated workflow helps businesses to offer a wider range of applications. Since the materials printed on the HP Latex R Printer Series can be processed flawlessly on the Summa F Series, no application will be too bold a challenge to create. Always with the highest quality level in mind.

Find practical similarities such as the dimensions of rigid and flexible materials that fit on the flatbed cutters, as well as the types of material that the flatbed system can easily handle. This is possible thanks to high-quality modules that can house multiple tools to efficiently apply multiple cutting techniques in one single job. For example, paper-thin, thick materials, rigid and flexible materials have no secrets for Summa's flatbed cutters. With which, in turn, all kinds of applications are made such as stickers, posters, beach flags and advertising displays.

About Summa

Every day, for more than 3 decades, Summa delivers the world's highest-quality vinyl and contour cutters, finishing flatbeds and laser cutters without compromise. Summa provides cutting edge solutions for the printing, signage, display, apparel and packaging industries. Summa's global headquarters is located in Gistel, Belgium.

-

Read more ...

Summa, a leading manufacturer of high-end cutting plotters, proudly presents two new sizes of their finishing flatbed systems. The F3232 and F3220 are based on the proven technology of the Summa F Series. Through the expansion of the flatbed series, Summa strives to improve the synergy with the large format digital printer market and to meet the needs of their customers. The new flatbeds are expected to be ready for shipment in February / April 2019.

Fully equipped for the textile market

Within the world of large format digital printing, most common sizes of textile printers are equipped with a working width of 3.2 m to be able to print large rolls of textiles. Both new Summa flatbed cutters, the F3232 and F3220, also cover a working width of 3.2 m, making them the ideal companion to process common, popular print sizes with utmost ease and accuracy.

The matching working area sizes of the textile printer and Summa’s new finishing cutter sizes will lead to a print and cut workflow, fitting seamlessly into each other and offering endless solutions to the flourishing textile market.

Geert Pierloot, Summa’s Product Marketing Manager, points out: “The new sizes of flatbed systems enrich Summa's platform with advanced finishing solutions, especially within the textile industry. Together with the recent launch of a more powerful High Torque Rotary Module (HT RM), both the F3232 and F3220 are the ideal workhorses to serve the textile market in the processing of all sorts of mesh fabrics, flags, and banners."

Processing large board material in a flash

However, not only the textile market will benefit from Summa's two new sizes of flatbed finishing systems. Then both flatbed sizes are also perfectly suited to cut the increasingly popular board sizes of 3 m x 2 m. Additionally, the F3232 with its working area of 3.2 m x 3.2 m, has the inclusive feature: Summa’s Tandem Mode. This feature will increase productivity of the customer’s workflow by using the front zones and rear zones alternately. The Tandem Mode will be most beneficial when processing board sizes of 1.5 m x 3 m. All existing tools and models within the F Series gamut are designed to fit each size of the flatbed range, the F3232 and F3220 sizes inclusive. This ensures the highest versatility to process all kinds of material and offer numerous high-end solutions to the sign making, textile, and digital print industries.

About Summa

Every day, for more than 3 decades, Summa delivers the world's highest-quality vinyl and contour cutters, finishing flatbeds and laser cutters without compromise. Summa provides cutting edge solutions for the printing, signage, display, apparel and packaging industries. Summa’s global headquarters is located in Gistel, Belgium.