-

Read more ...

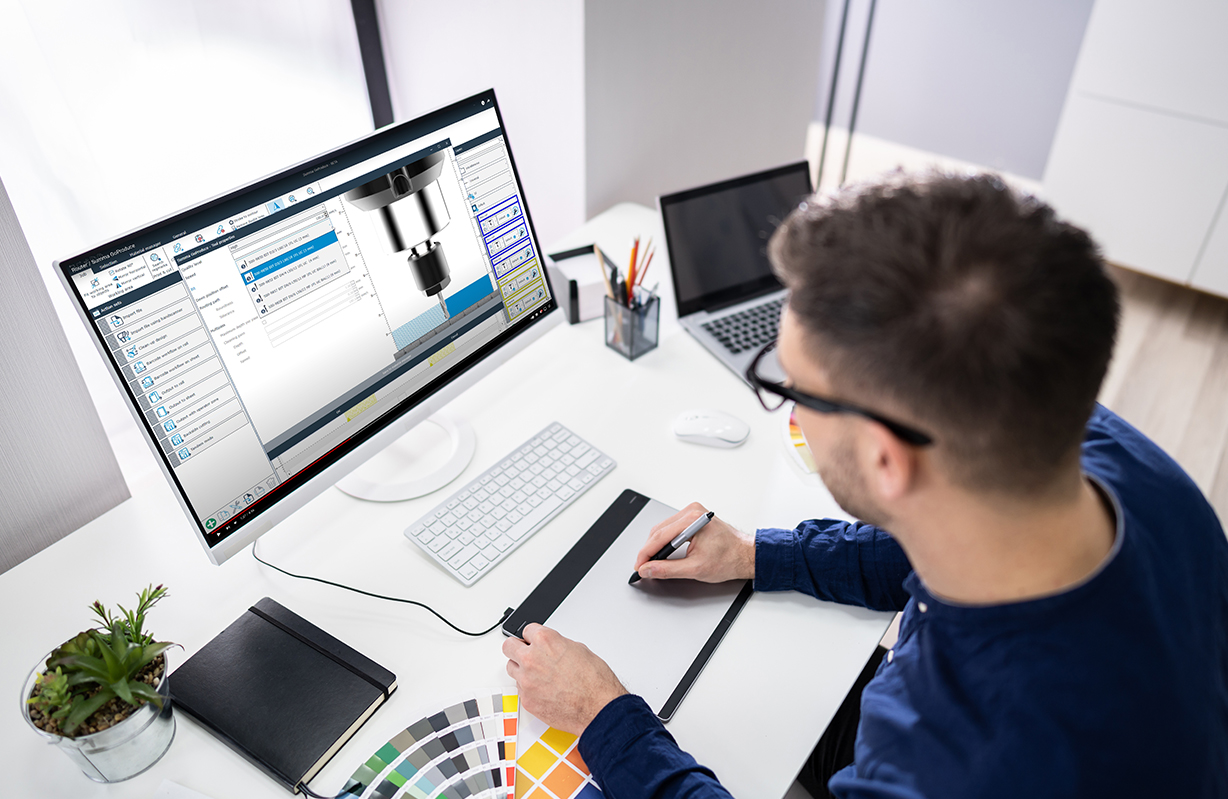

Every single one of you, working with printed or non-printed materials to cut and finish, know how vitally important software is to the usability and productivity of your hardware. This is not just a matter of integrating your print and cut workflow. Also, the presence of an intuitive interface, easy navigation, and intelligent features help the operator handle jobs more efficiently.

Summa recognizes the importance of software that is fully tailored to the hardware. To underline the importance, Summa developed its very own software platform entirely in-house: GoSuite. GoProduce for the F Series has been the first software module within GoSuite, which is designed to optimise the F Series users' workflow.

Smart functionalities at your service

Adding to the intuitive interface and modern look, one of the true strengths of GoProduce are the straightforward action sets, enabling the operator to handle variable jobs in a natural, trouble-free and automated way. There are various default action sets in GoProduce to support your Summa workflow, such as the barcode automation, ready to be used at a click of a button. To further enhance flexibility, you can adjust many of these action sets to your hand and your needs.

Discover the Material Database

The material database is a vital key to the user-friendliness of the GoProduce software. It includes an extensive range of material types, the materials contain the cutting settings and tool data defined by Summa. These materials can be adapted to your specific needs at all times.

The database ensures a smart collaboration between jobs, materials, and on-site tools. The material manager works with pre-defined methods, meaning that you only need to choose the material you want to process and the material manager itself automatically chooses the correct tool and its settings to process it with.

Supporting Back Side Cutting with edge detection

Back side cutting is especially useful when cutting cardboard boxes in order not to damage the print and in order to ensure the print is located on the outside of the box. GoProduce includes a specific camera profile enabling you to perform backside cutting with smart edge detection;

Basically, there are two methods of back side cutting within GoProduce:

- Original: in this method, the camera will first read the marks in the artwork. The marks will then be cut out in squares. After that, you need to flip the sheet, the camera starts reading these cutout marks again and the flatbed cutter starts to cut.

- With edge detection: this method is available since the 1.10 version of GoProduce. The camera will read the marks in the artwork first and then it will read 3 edges of the sheet. Thereafter, you flip the sheet and the flatbed cutter will read two edges again to determine the position of the artwork. The machine starts to cut without the need to cut out the markers first. This will save you a considerable amount of time.

Automated Workflow with Barcode functionality (Pro Pack)

The flatbed cutters usually need an operator to select the right cutting file, then read the printed marks to register the correct position of the material and match the selected cutting file. With the barcode functionality, the cutter reads the printed barcode, identifies the job, and automatically retrieves the cutting file. In this file, all the necessary cutting data and tool selection can be stored thanks to GoProduce. The built-in camera of the flatbed scans the job automatically (or alternatively by hand scanner). See how it works in the video below:

Continuous development of new features and improvements

The GoSuite software range is growing and Summa continues to develop new features and improvements. The GoSuite software platform is built to support you today and in the future, with many more software solutions to follow. With GoProduce for the Summa F Series, you can benefit from all the latest features and techniques on your F Series cutter. Did you know that you can easily upgrade your SummaFlex software to GoProduce?

-

Read more ...

Enhanced performance, quicker, more productive, more efficient, better outcome and facilitating the operator’s life, are only a few of the many benefits you can achieve with the upgrade possibilities on an F Series flatbed cutter from Summa.

Did you know already that our F Series flatbed cutters can be enhanced with a range of upgrades and add-ons according to the pace of your company’s growth, aspirations and goals? We gladly point them out for you below.

1400W ROUTER MODULE

The 1400W router module – which can be purchased at an entry-level price - offers an attractive performance increase with improved output quality over the standard router. The router is capable of handling the most used solid boards in the Graphic Industry. It is suitable for milling, contour cutting, polishing and engraving. (Available add-on for all F Series models)

F-PERFORMANCE MODE

The F-Performance mode ensures an increase of up to 40% of the F Series’ performance. Advantages include faster up, down and turning movements of the cutting head, which will be most remarkable when using the Kiss-cut tool. Also, feeding material will happen significantly faster. The job will be finished practically twice as fast without compromising an inch on quality. (Available add-on for all F Series models)

Note: The F-Performance mode is available as free unlock on new machines and as payable unlock on older F Series models, built before 2018.

CONVEYOR EXTENSION

Thanks to the conveyor extension, the F1612 makes light work of cut designs, that are much larger than their actual cutting area. Once the first part of the job is completed, the conveyor feeds the cut material to the extended front where it can be removed easily and safely, while the machine is cutting the next part. This minimizes downtime considerably. (Available add-on for the F1612 model)

Note: All existing F1612 units in the field can be upgraded with this option.

BASKET

The basket is a handy accessory to reduce the media handling time, thus optimizing your workflow. The F1612 can automatically process several feet of material while the basket is capturing the cut-out vinyl and/or waste material. Rely on an efficient cutting workflow and a clean work environment. (Available add-on for the F1612 model)

EXTENSION TABLES

The sturdy, foldable Extension Tables can be placed in front and at the back of an F1612. They are adjustable to set the correct height. This way, board material longer than the F1612 working area can still be processed. With the extension tables, you can use the continuous sheet feed feature, which enables the user to load and unload material while cutting. The feature helps to avoid idle periods during the processing of material and thus adds significant value to the overall workflow. (Available add-on for the F1612 model)

ROLL-UP SYSTEM

When kiss-cutting, the roll-up system winds the material back on a roll after it has been cut. This allows the F1612 to work unattended while keeping the work area neat and clean. When cutting through, a workflow can be set up in combination with the basket or extension table. The roll-up takes care of the waste matrix while the operator collects the cutout material. The winding roll is also easily accessible for trolleys or other tools to handle heavy rolls. (Available add-on for the F1612 model)

HEAVY-DUTY ROLL SUPPORT (HDRS)

The Heavy-Duty Roll Support can be used on our wide format flatbed sizes to allow a straight and effortless throughput of heavy print rolls before cutting the material. Especially for the processing of heavy banner material, non-stretchable wide textile rolls and lightly stretchable materials, the HDRS will prove its worth. It will even allow the processing of rolls up to 200 kg with ease. (Available for F1832, F3220 and F3232 models)

BARCODE WORKFLOW WITH THE GOPRODUCE PRO PACK

The Summa barcode workflow on the F Series generates an automatic process of identifying and opening cut files to start cutting an entire roll without user intervention. This optional feature will increase your productivity and enhance flexibility substantially whilst freeing up time for the operator to attend to other assignments.

Note: the automated barcode workflow, based on the F Series’ built-in camera system, is included with the Summa GoProduce Pro Pack (one-time purchase).

For SummaFlex users: possibility to upgrade to GoProduce Flatbed Edition software

For flatbed machines shipped as of March 1, 2019, the GoProduce Flatbed Edition Software is included. But if you happen to have an older F Series unit, you may be still working with the SummaFlex software. Now, if you want to keep up with the latest features, and updates and ensure you can use the latest techniques on your F Series equipment, we do recommend upgrading your software to the GoProduce Flatbed Edition software. -

Read more ...

Summa nv, a leading company of high-end cutting plotters and finishing systems, has developed a new in-house software platform to support its product range: GoSuite. The first software module within this GoSuite platform is called GoProduce. The software is bound to facilitate the operator’s work on the F Series flatbed and secure optimum rentability at the customer, partner, and installer production sites. The GoProduce software is ready for immediate release and implementation worldwide.

Advance with the right software

Flatbed cutters are the customer’s hardware of choice when they need to get to market fast. With this speed ever-increasing, the software needs to be up to par to make sure the hardware can keep a more than steady pace at the smallest error margin.

With the F Series as the fastest growing series in the Summa range, Summa selected this series as the first one to be accompanied with software to match. Instead of optimising or tailoring existing solutions, Summa opted to develop the new software platform entirely in-house.

GoProduce offers the following functionalities:

- Flexible and tailored import of files to ensure a smooth print and cut workflow integration

- Extensive material database which is able to automatically select the ideal tool and its settings based on the material

- Integrated tutorials for direct support, also available on Youtube

- Registration of square or round marks, supporting all RIPs and PDF formats & many more…

To secure an easy integration and implementation worldwide, the Summa development team made sure the software has:

- A modern look and feel with an intuitive interface and easy navigation

- Straightforward action sets for fast automated production

- Smart options for fast routing and quick problem fixing

- A tailorable and extensive material database

- Workflows and functions defined and customisable to the customer’s needs

Plug and play

The software was designed to be plug and play specifically, without any need for hardware installation. Users simply install the drivers, activate their subscription online and start operating. Geert Pierloot, Product Manager at Summa, explains: “When business is booming, there is no time for extensive training, so we wanted to keep the software as intuitive as possible so it could be implemented quickly and used immediately. Throughout March, we’re having training demonstrations and webinars planned for our dealer network and will be posting YouTube tutorials regularly so people can make the most of the functionalities. The beta tests went smoothly, and users are excited about the user experience and positive results. We’re eager to get the market’s feedback on GoProduce.”

GoProduce for the F Series is intended to make life easier on the operator, by facilitating workflows via action sets. A quick implementation will secure immediate operability enabling any operator to maximise the potential of his F Series cutting and finishing systems.

Legendary performance meets future-proofed profitability

Wim Maes, Executive Member of the Board at Summa, reflects on the importance of GoProduce for the market: “Summa is expanding its product range and is venturing into new markets. We’re convinced software is the efficiency differentiator for companies to become even more productive. So, when we researched on how to grow our solutions’ portfolio with software, we realised we had the in-house expertise to start afresh and provide our customers with the consistent quality and customer service they expect from Summa. We’re proud to say we can now fully tailor our software to our hardware to ensure our customers get to be as efficient and productive as possible.”

“GoProduce is but the first step in the future direction of cutting and finishing. We aim to stay a frontrunner, by making sure software and hardware are fully aligned for the best profitability and operational stability for any customer and operator in the large format, signage and textile markets. These software advances will future-proof the legendary performance our customers attribute to our solutions.”.

Skip to Content

- Create an Account

- Offers for you

+44 (0) 1527 853 136