Vinyl Cutters

-

Read more ...

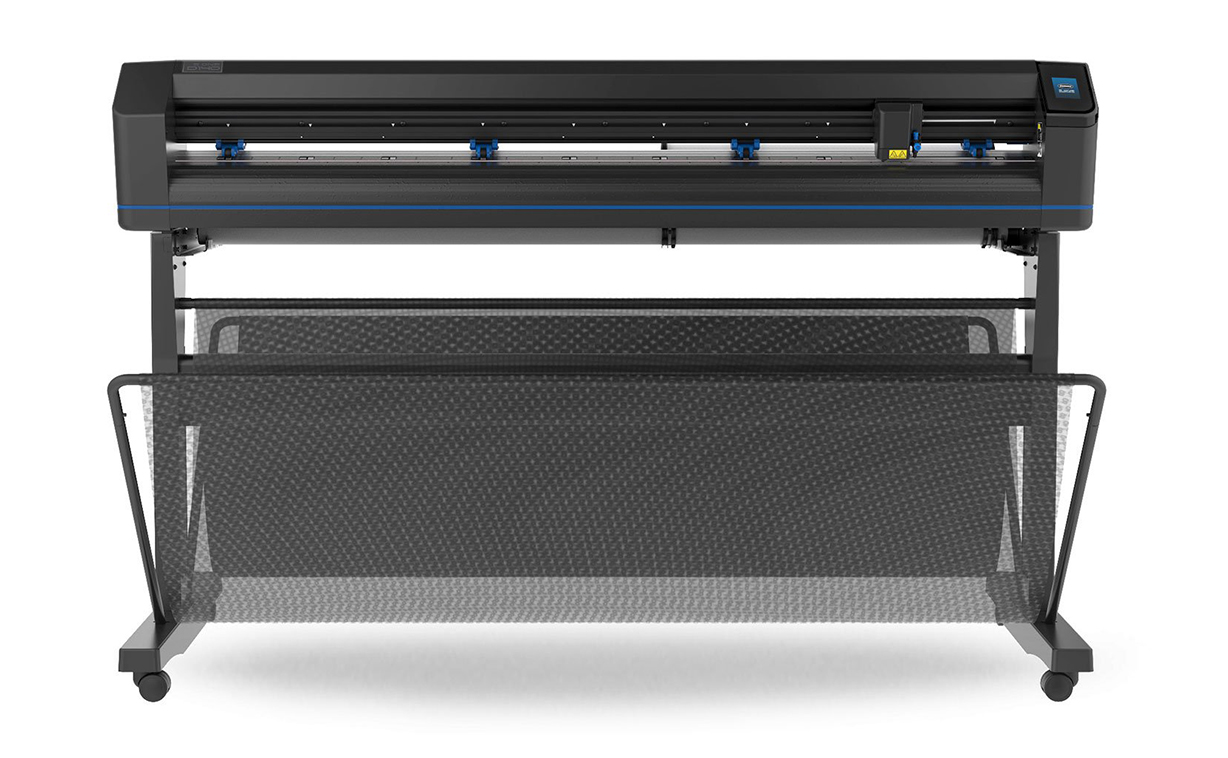

When it comes to professional sign-making, having a cutting plotter that is fast, efficient, and versatile is an absolute necessity. Enter the Summa S Class 3 – the epitome of precision and flexibility. With a wide array of applications that set your business apart, this cutting-edge machine is a game-changer. The application possibilities are endless, but we summed up the categories where the S Class 3 truly excels!

1. Large Signs Make a BOLD Impression

The Summa S Class 3 is your ticket to making a BIG impact with signage. From crafting captivating floor graphics and stunning wall designs to producing eye-catching window stickers and precise lettering, this machine handles it all with finesse.

Need your message to hit the road? Our roll cutter ensures your graphic vehicle designs are nothing short of head-turning. Seeking privacy? The S Class 3 effortlessly transforms your windows into advertising masterpieces while safeguarding privacy from within. And when it’s about grabbing attention indoors, totems and other interior advertising are a breeze for the S Class 3.

2. Small Text and Intricate Designs: Precision at Its Best

The S Class 3 is your ultimate solution for handling small letters and intricate designs with unparalleled precision. What sets it apart? Summa’s Tangential cutting technology! Unlike traditional drag knives, this innovative tech lifts and reorients the knife in corners, resulting in even sharper and more precise cuts.

But that's not all – the Summa S Class 3 boasts Smart Object Sorting, selecting the most optimal starting point for cutting, and Smart Panelling, ensuring efficient cutting of all objects within a set range.

From promotional items like flawlessly cut keychains and magnets to small signage such as nameplates, directional signs, and room numbers, this machine does it all. Labels and tags, both for products and organisational needs, find their perfection here. And, of course, custom apparel enthusiasts will love the S Class 3 for creating personalised T-shirts, hats, socks, and more.

3. Every Type of Sticker Imaginable: How a-peel-ing!

Take your sticker game to the next level with the S Class 3! This machine optimises your print and cut workflows like never before, thanks to FlexCut.

How does Flexcut work? One length is cut completely through the material, while the other is cut halfway through, creating a perfect tear-off line. This ensures your material stays rigid during transport through the Summa cutter yet remains easy to remove from your design afterwards.

The possibilities are boundless! Whether it's standard vinyl stickers, kiss-cut stickers, die-cut stickers, clear stickers, bumper stickers, holographic stickers, transfer stickers, or window clings and wall/floor stickers, the S Class 3 handles them all with precision and ease.

4. Thick, Thin, and Tough Material

Standard laminated vinyl is not the only material that can be cut with the S Class 3. Thanks to the tangential cutting head, all types of materials of non-standard thickness can be cut. This opens up a whole new array of cutting possibilities!

When we talk about thin materials, we are referring to substances thinner than standard sticker vinyl, like car wraps. In contrast, thick and tough materials (which tend to be the same materials) are materials that can be up to 1.2mm thick, such as laminated vinyl and folding carton.

5. Creasing: When folding under pressure is a good thing

Only available on Summa cutting plotters is the possibility to not only cut but also crease. In fact, the new Performance Head can cut and crease during the same job, i.e. without having to change tools or having to stop the machine.

The creasing function is perfect for short-run applications. For example, to make exclusive gadgets for events or companies in folding carton.

Folding carton is incredibly versatile in its applications. Combining it with the S Class 3 can lead to some great results. For example, you can make some high-quality restaurant menus as well as personalized greeting cards for special occasions. Short-run leaflets, as well as folders, can be made with an S Class 3. Creating customized little boxes is an option, too and can be used to hold small presents or business cards.

About Summa

Every day, for over three decades, Summa has delivered the world’s highest quality vinyl and contour cutters, finishing flatbeds and laser cutters without compromise. Summa provides cutting-edge solutions for the printing, signage, display, apparel and packaging industries.

-

Read more ...

The Summa S Class 3 is a state-of-the-art device designed for professional users who demand top performance in their cutting applications and want to explore new opportunities. At the heart of the S Class 3 is its unique True Tangential Cutting Technology, ensuring top-notch performance. The addition of the all-new OPOS Camera with onboard image processing provides ultra-fast mark recognition and processing, making print & cut workflows smoother and more efficient. The performance head is the most advanced in the vinyl cutter series and can now automatically switch between cutting and creasing, perfect for short-run packaging jobs, and setting a new standard in the industry.

High-Precision & Unrivalled Performance

The S Class 2, a proven performer, has been on the market for ten years. It is not only unmatched (still!) by its competition, it is also very much valued by its customers. "For the S Class 3, we kept the good and proven. And while they may look similar under the hood at first sight, a lot has been upgraded. The latest electronics made it possible to achieve faster responsiveness, better data processing, and more precise motor control, resulting in a smoother, faster, and more reliable result.", says Randi Kerkaert, product manager.

Reliable & Versatile Cutting

Nowadays, vinyl cutting is probably not the hottest topic in the Sign & Display industry. "The long lifetime of every Summa vinyl cutter allows sign shops to avoid the need for further investments in vinyl cutting equipment. On the other hand, having a premium cutting plotter available on the work floor remains essential and critical for many businesses", states Christof Van Driessche, CCO at Summa. "A reliable cutting plotter is much appreciated even in an industrial environment. With the introduction of the S Class 3, we aim to provide new opportunities for sign shops to expand their current vinyl cutting businesses and explore new territories, like cardboard cutting and creasing."

The S Class 3 will be available in from the 5th September 2023. Check out all the details of this amazing product, including the barcode workflow with enhanced roll-up system, its Performance Head and the all-new OPOS Camera.

About Summa

Every day, for over three decades, Summa has delivered the world’s highest quality vinyl and contour cutters, finishing flatbeds and laser cutters without compromise. Summa provides cutting-edge solutions for the printing, signage, display, apparel and packaging industries.

-

Read more ...

In the sign & digital industry and beyond Summa is known to be one of the forerunners when it comes to roll cutting technology. To date, the company has provided many sign-making companies infinate and reliable cutting solutions with its roll cutter series. But standing still is not an option and product development and innovation are highly regarded purposes for Summa.

Therefore, Summa is proud to announce a brand new roll cutter product line which is called S One. The S One Series is the next step in Summa's mid-level roll cutting machines and replaces the former SummaCut roll cutter series. To optimise quality ergonomics as well as efficiency, the S One Series is built completely from the base, using the experience and knowhow acquired over years of developing roll cutters. The name S One refers to the core idea behind its development:

The One to change the game.

Increase productivity, quality and capabilities

The S One series not only showcases a new, sleeker and more modern look. It also embodies add-ons and enhanced features for better quality, improved ergonomics and higher productivity. The improvements and additions include:-

- User-friendly GoSign software to manage cutting workflows with great flexibility

- Efficiently drag cutting head, allowing up to 600 grams of cutting force

- Ergonomic touchscreen, allowing for effortless navigation

- Robust OPOS sensor, increasing the speed at which registration marks are read

- Improved internal intelligence, minimising human errors and operator intervention

- Excellent tracking performance for ultimate accuracy

- OPOS Xtra functionality for flawless processing of very small sticker jobs

- Smart FlexCut feature, enabling to perforate material to remove the deisgn out of its carrier easily

Future-proof cutting solution

The products developed by Summa stand out for reliability, longevity and versatility. Faithful to this tradition and conviction, also the new S One product line is built according to strict requirements, specific to Summa products. The S One series is, therefore, designed with premium up-to-date components for long durability. Moreover, its combination of innovative features makes the S One roll cutter a flexible and future-proof unit, able to grow along with the customer's business aspirations and goals.

Christof Van Driessche, Chief Commercial Officer, Summa adds: "With the experience and dedication on board, Summa continues to show true leadership as a supplier of high-end cutting solutions. The introduction of the S One roll cutter series is yet another milestone in Summa's large history of legendary performance. The S One Series will unquestionably bring added value and innovation to many sign makers' cutting workflows.

About Summa

Every day, for over three decades, Summa delivers the world's highest-quality vinyl and contour cutters, finishing flatbeds and laser cutters without compromise. Summa provides cutting edge solutions for the printing, signage, display, apparel and packaging industries. Summa's global headquarters is located in Gistel, Belgium.

-

Read more ...

If you weren't convinced already, we will make sure you will be now! Read the following post on 6 reasons to choose our Summa roll cutters above any other available on the market. Obviously, there are more than 6 reasons, but type space is limited, so here we go!

1. True Tangential Technology

A True Tangential head has a motor, controlling the direction of the blade at all times, enabling to cut thick and hard substrates with unsurpassed high detail and quality. Summa offers a True Tangential cutting head, enabling to cut materials quickly and concisely up to 47 mils thick. All other cutters in the market use drag (swivel) cutting heads and an improved process called “Tangential emulation”. Tangential emulation tries to simulate this control but does not have any motorised control over the blade. Consequently, tangential emulation will never provide for the same accuracy than if you were to use a cutter with a True Tangential cutting head.

2. Repeatability

‘Repeatability’ is a term, which refers to how accurately the cutter keeps cutting whilst media is being transported. The repeatability guaranteed on the SummaCut line of cutters is 8 m (26 ft.); on the S Class 2 line, this would be 12 m (40 ft.). The closest competitor in the market only guarantees 1.9 m (6.5 ft.), which is quite a difference. It is important the cutter is able to process the appropriate dimensions accurately at all times, which can be guaranteed with Summa’s repeatability feature. Note: All cutters are measured on a spec called ‘tracking’. However, ‘tracking’ only defines how accurately the transport of the media occurs. This could be misleading because it doesn’t specifically refer to the movement of media whilst cutting.

3. Barcode Feature

Unique to Summa is the ability to read barcodes with the onboard sensor. The barcode will automatically communicate with the software to retrieve the necessary cut data and initiate the cutting. After finishing the job, the cutter will automatically search for the next barcode and repeat the process. This allows for an entire roll of printed graphics to be cut without user intervention. Maximal automation and productivity are yours to enjoy!

4. OPOS Sensor

Summa uses a “white light technology” to recognise registration marks and barcodes. The Summa OPOS (white light) sensor is able to detect registration marks on all UV protection films. Other cutters in the market are still using the old IR (Infra-Red) light. However, all laminates have built-in UV inhibitors nowadays. When using these old IR sensors, the cutter will encounter difficulty to recognise (be able to find) the registration marks because the UV light is being filtered by the UV protected laminate. The OPOS sensor is also capable of registering other colours beyond black on white (dark, blue, grey, etc..).

5. Unique Summa Line: S Class 2 OPOS CAM Series

Summa offers the possibility to have a camera – OPOS CAM – mounted on the cutter instead of a light sensor. The main advantage here is speed. The OPOS CAM system can register marks 10 x faster than any light sensor. This is a considerable increase in productivity, especially when processing entire rolls. Another advantage is the ability to create a “camera profile” for every challenging media type (ie. reflective). This profile will enable the cutter to register marks on any substrate because the profile can be created specifically to the media type.

6. G-Performance, boost your S Class 2 performance up to 40%

Transform your S Class 2 cutter into a lean, mean and faster cutting machine than ever before thanks to the G-Performance feature. No matter whether it be a cutter with tangential or drag knife technology or our smallest or largest cutter in the product range, the G-performance will exceed every model's speed limit. However, speed is not the only advantage you will benefit from. Your S Class 2 cutter will be able to also read registration marks, to achieve a perfect cut, even with print deformations, at an ever faster pace!

-

Read more ...

Even though the phrase "time is money" is almost as old as time itself, it still applies to small and big companies of today. Summa, value your time and will continue researching every way to improve your workflow. Summa makes your dream come true and enables you to divide your job time almost in half thanks to the release of the G-Performance mode. This mode is specifically designed to enhance the speed/performance of digital finishing operations on the S Class 2 roll cutters up to 40%, which will save you precious time to spend on other things.

Transform your S Class 2 cutter into a lean, mean, even faster-cutting machine than before with the G-Performance, no matter whether it be a cutter with tangential or drag knife technology or our smallest or largest cutter in the product range. However, speed is not the only advantage you will benefit from. Your S Class 2 cutter will be able to read registration marks, to achieve a perfect cut, even with print deformations, at an ever faster pace!

No matter how wide the substrate and/or machine, the advantages of the G-Performance will definitely show in production times. The G-Performance mode is available as free unlock on new machines (2018). However, even S Class 2 cutters, built before 2018, can experience the full benefits of the G-Performance mode as well. Especially within large industrial environments, this G-performance mode will prove its worth and give your overall workflow a serious boost.

Make your dream a reality and release the G-Performance mode on your S Class 2 vinyl and contour cutter! Unlock your boost extension at www.summa.eu/g-performance!

Not convinced? Have a look at a side by side comparison of two S Class 2 cutters, one with and one without the G-Performance mode.

Why stop there?

And while we're at it, Summa released even more features (for free!) to enhance the finishing experience with your Summa S Class 2 cutters. Check it out!

Short Load

This new functionality on the S Class 2 cutters ensures less material will be forwarded, so possible material obstructions are avoided. The fixed size of the autoload of the media is 80 cm. Not only does the short load mode makes sure the material will not touch the floor or be hindered by obstructions, it also guarantees less waste of material, which contributes to the overall user-friendliness, the environment (less waste=less pollution) and your wallet!

Dog Ear Function

Thanks to the updated intelligence on the Summa S2 Series, dog ears (pleated corners) in the substrates will be avoided during loading. Before, the cutting head would immediately start on the right side of the media during loading, which could then lead to these pleated corners. With the dog ear function, the head will first position itself on top of the media during loading and will position itself on the right side afterwards. As a result, damaging the product will be avoided and a clean cut can be yours to admire!

OPOS XY2

OPOS has the unique ability to register multiple marks along a job. With the OPOS XY2 function also the additional XY line at the end of the job will be read now, which will lead to more compensation possibilities in deformation and even more contour cut accuracy than before, especially when cutting large jobs. No restriction, only unsurpassed accuracy, and impeccable precision!

The new S Class 2 screensaver is more informative, which will enhance user-friendliness to the fullest. Moreover, instead of the Summa logo, tips will be shown to make sure ultimate efficiency will be reached during the job.