-

Read more ...

Sustainability. Many businesses are embracing it because it is becoming an increasingly important issue in modern society. Therefore, libraries are also searching for opportunities to become more sustainable. Currently, a lot of plastic is still used to protect books. Nevertheless, book covers with book protection film are necessary to protect them against damage, moisture, and dirt. An additional advantage is that the books with protection film are easy to clean and disinfect, which is of great importance in times of a pandemic. Covering books with bio-based film made from sugar cane instead of 'regular plastic' is a big step in sustainability. Read more about the advantages of the bio-based film Filmolux® soft organic in this blog.

Sugar cane as a sustainable solution: Filmolux® Soft Organic

In addition to Filmolux Libre Organic, there is now also Filmolux® Soft Organic. An environment-friendly and antibacterial book protection film that is very easy to apply. The film is made from a bio-based polyethylene derived from the renewable raw material sugar cane. Sugar cane is a versatile and rapidly renewable crop that can be used as a clean source of energy and as a raw material for the manufacture of many products. Unlike conventional polyethylene that is produced from fossil materials, the green polyethylene from sugar cane contributes to the reduction of greenhouse gas emissions. And there is an excellent sustainable process behind it.

The six advantages of Filmolux® Soft Organic

Filmolux® Soft Organic is ideal for application to smooth surfaces such as covers of smooth paperbacks, comics, paper covers, brochures, and folders. There are also other advantages to using Filmolux® Soft Organic:

- Environmentally friendly - Made from bio-based polyethylene derived from sugar cane.

- Simple bubble-free application - Small mistakes made during the covering process on smooth surfaces can be easily corrected.

- It can be cut to size - The silicone paper cover with grid simplifies cutting.

- APEO and BPA free - Produced according to REACH.

- Easy to clean - The material itself is easy to clean or disinfect. This is especially important in times of pandemics. The antibacterial effect is tested according to ISO 22196.

- Optimal protection - Book covers with book protection film protect books from damage, moisture, dirt, and wear. As library books pass through many hands every week, book protection films are necessary to keep the book nice and clean, especially in times of a pandemic.

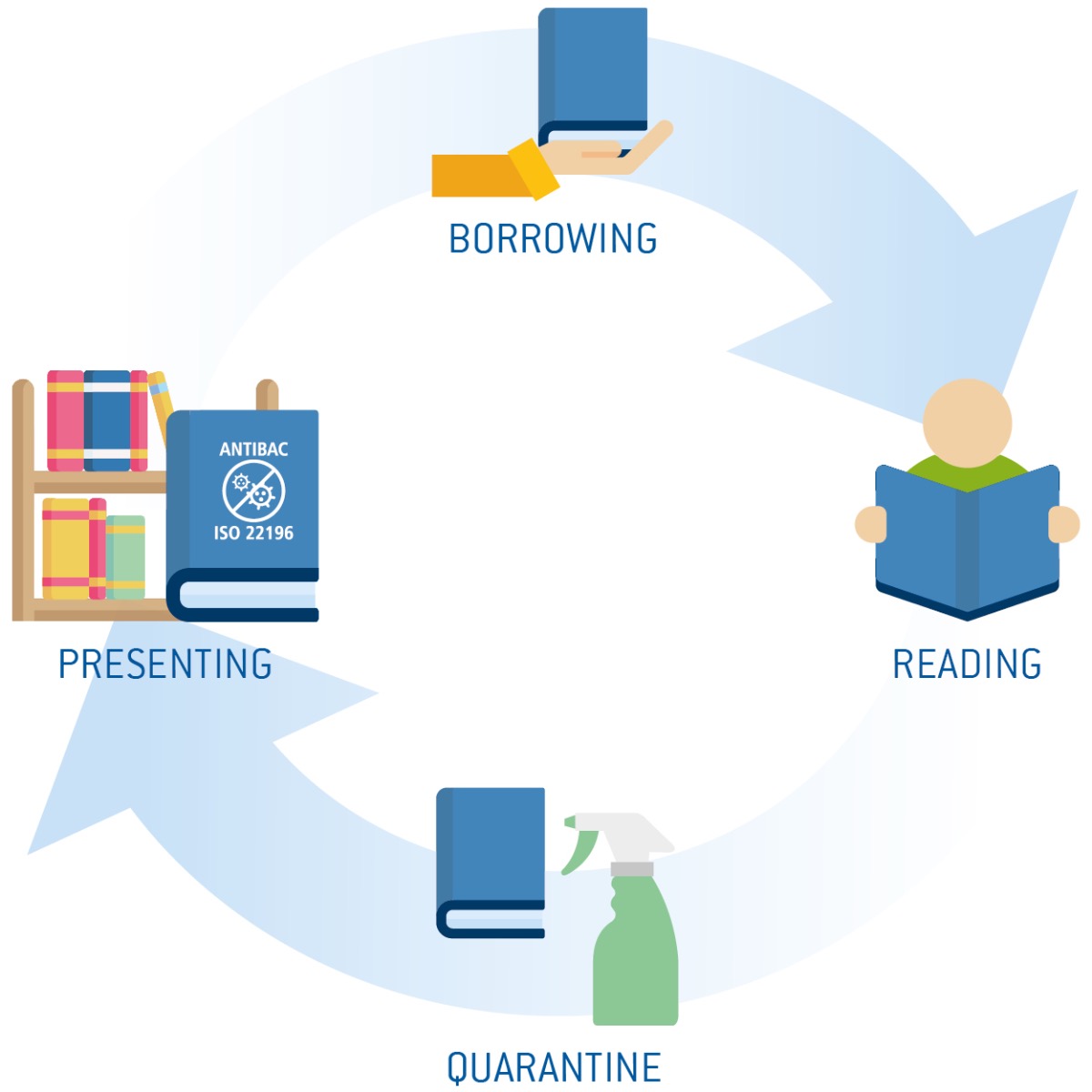

Cleaning and in times of a pandemic

Easy-to-clean covers are a great advantage for libraries and any other places where many people use books. An essential part of a safe hygiene concept for book rental is the nature of the film itself. Many of the Neschen book protection films have an anti-bacterial effect. We have had this tested and proven by an independent institute according to ISO 22196. After 24 hours, 99.9% of all bacteria on the protective film were eliminated. We recommend a strict hygiene approach because of the Covid 19 pandemic. After cleaning and an additional 1-day quarantine, a book with Neschen antibacterial film can be lent out again without risk. A safe concept for the reader and the library.

-

Read more ...

Book protection films have many advantages: In addition to protecting against damage, the books‘ covers are easy to clean and resistant to a wide range of cleaning agents and solvents. The easy-to-clean covers are a big advantage for libraries and any other location where books are handled by many people. Nevertheless, there are a few points you should consider when cleaning your wrapped books, a well-considered hygiene concept can help.

Books that are handled by many different people should be cleaned regularly.

The Neschen hygiene concept

An essential component of a safe hygiene concept for book rental or loan is the nature of the film itself. Many of the Neschen book protection films have an anti-bacterial effect. We had this tested and proofed by an independent testing institute according to ISO 22196. After 24 hours, 99.9% of all bacteria on the protection film have been eliminated. We recommend a strict hygiene approach due to the Covid 19 pandemic. After cleaning, and an additional 1-day quarantine, a book with Neschen antibacterial film can be returned to the rental shop without any risk. A safe concept for the reader and the lender.

Cleaning book protection films

In order to prevent dust particles, small grains of sand or other particles from damaging the surface, damp cleaning is recommended for book protection films. A special cleaner for films is not necessary and conventional cleaning agents can be used. A mixture of warm water and detergent is very effective. However, very aggressive or abrasive cleaning agents are not suitable.

Disinfecting book protection films

How the book protection film can also be disinfected and not just cleaned, depends on the film.

To select the right kind of disinfectant, take into consideration which types of micro organisms are to be killed. Additionally, it is important to keep the agent’s effect on the material in mind. Not every surface is compatible with all types of disinfectants. Under certain circumstances, some book protection films can be damaged by the use of certain chemical compositions.

To clean book protection films thoroughly, it is wise to disinfect them with a liquid agent. Disinfection with gases (such as ethylene oxide) and radiation (beta or gamma rays) is not possible with book protection films.

Liquid disinfectants are based on a mixture of

- Ethanol

- Isopropanol

- Glycerine

- Hydrogen Peroxide

- Distilled Water

However, these components can have a negative effect on plastic, depending on their concentration, exposure time and temperature. Additonally, the reaction depends on the plastic material itself because every type of surfaces reacts differently to these chemicals.

Disinfecting PVC-based book protection films

Book protection films made of PVC are sensitive to ethanol and isopropanol. The result: The film becomes brittle if it repeatedly comes into contact with these substances. The two named chemicals dissolve the plasticisers and the alcohol penetrates the film, causing it to swell up. Afterwards, the film will feel sticky.

Disinfecting PP-based book protection films

When it comes to disinfecting PP-based films, it is important to know that hydrogen peroxide can damage the surface more easily due to its oxidation effect. The other components (ethanol, isopropanol, glycerine and distilled water) do not harm the material and are a good choice.

Disinfecting PE-based book protection films

In regards to disinfection, PE-based films are very similar to PP-based films. You are on the safe side, when simply following the same guidelines as for the PP-based variety.

Note: All book protection films should be cleaned or disinfected carefully, otherwise the surface will get scratches from the cleaning motion, resulting in the film’s transparency to be lost.

Avoid direct contact with liquid disinfectants, but use one-way tissues soaked with the desinfectants and wipe off the book covering films. Let the books dry completely before further use or storage.

-

Read more ...

Whether library stock or a privately owned page-turner - books that we want to preserve in the long run can be protected against damage simply with a range of easy-to-use products from Neschen. In this article, we present some helpful tips for preserving your books.

Simple solutions for paperback covers, book spines, labels, or book pages

Everyone who likes books knows, they get pretty worn out after a few years. In public libraries, this process takes place even faster. After a short amount of time, some books need to be replaced altogether. To save money and resources, many of the most commonly occurring damages can be easily repaired or prevented altogether. This way, you can preserve the book in the long run.

Quick and easy application

Filmolux® Soft is a protection film that is very easy to apply and that allows for small application errors to be corrected easily. There is also a PVC-free alternative - Filmolux® Soft PP. Thanks to their reduced initial strength, it is very easy to apply the film bubble-free. With the grid on the back liner, the film can be cut into shape.

Reinforcing or repairing the inner book spine of paperbacks

Anyone who likes to read paperbacks knows the inner book spine is usually one of the parts that get damaged first. It is a pity if a favourite book falls apart completely. In public libraries, the books are exposed to even greater strain. Unfortunately, some readers do not always treat the books with care.

Fortunately, this damage can be avoided or even repaired relatively easily. With Filmoplast® P90 you can strengthen the inner book spine efficiently. The self-adhesive, wood-free and tear-resistant special fleece is easy to apply and protects your books from falling apart in the long run.

If you do not want to spend the time or money to equip all books before the damage occurs, Filmoplast® P90 is also an excellent choice. Dismantled book spings and torn out pages can be effectively repaired.

Preserving book labels

Almost every library uses self-adhesive labels for inventory management. Unfortunately, these come off quickly. Having to constantly renew the labels not only causes avoidable costs but also takes a lot of time.

Filmolux® 609 label protection is a good solution. These pre-cut protective films can be easily removed from the silicone paper. The product is a self-adhesive, glossy, crystal-clear soft PVC film with spontaneous initial adhesion.

For libraries, it is a great benefit that Filmolux® 609 is washable and resistant to a wide range of cleaning agents and solvents. This film is coated with a solvent-free, age-resistant and permanently elastic acrylic adhesive.

-

Read more ...

Protecting what is valuable: Neschen is regarded as the inventor of self-adhesive products for the professional repair and protection of books and documents. We are proud to say that these products are often taken off the shelf or are regularly, eventually take damage. These damages can range from torn or loose pages to damaged book spines. Replacing books can create high additional costs for libraries. Since prevention is always better than repairing the damage, it is a wise decision to protect or strengthen books and papers. This increases durability and saves costs.

Protecting history | Preservation of Documents

Besides being used for books, our products are used to repair and protect important documents. Many of the Filmoplast® line of products have a special composition that works perfectly with the chemical composition of aged paper and the ageing resistance of several products has been assessed and certified by the Foundation for Paper Technology (PTS) in Munich

Filmoplast® R for example is used in the Political Archive of the Federal Foreign Office in Berlin. The Political Archive is almost like a "memory" of the German Foreign Service. Twentyseven kilometers of shelves containing diplomatic documents since 1871, including 35,000 international treaties and countless personnel records bear witness to history. The material is accessible to everyone within the framework of the legal provisions. In the public reading room with 32 sears, more than 1,000 visitors per year inform themselves about historical contexts.

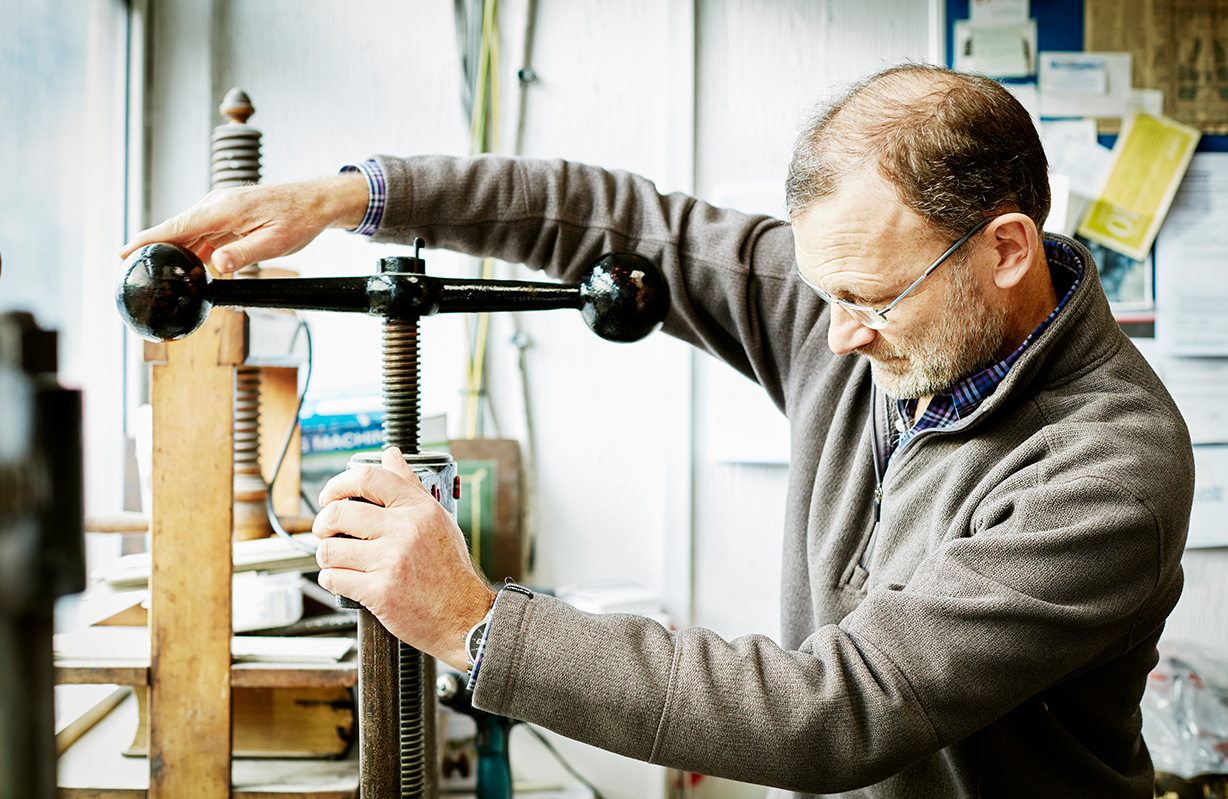

The archive also holds its own restoration workshop, in which employees process damaged archive materials. These include 75 meters of shelf space for fire-damaged files from World War II. The experts bring the archive records into a condition that protects them from further decay for as long as possible and that allows them to be worked with.

Important historical documents, which were partially damaged by fire during World War II, have been sealed with Filmoplast R to preserve them from further damage. Since the mid 1990s, the staff of the restoration workshop have been using Neschen Filmoplast® R for their work.

Filmoplast® R is a wafer-thin, transparent, technical Japanese paper for mass conservation. It is also an ideal material for the preservation of modern papers and newspapers (for wood pulp papers, approx. from the middle of the 19th century). Woodpulp papers contain acid (lignin), which attacks the paper from the inside. This valuable documentation of our past will destroy itself. When encapsulated in Filmoplast® R the magnesium carbonate in the adhesive neutralizes acids and prevents migration through the adhesive layer into the Filmoplast R paper layer, thus stabilizing the encapsulated document. Due to the low thickness of the material Filmoplast® R is hardly visible. The paper character of the original is preserved. Encapsulated book pages can easily be put together again as a book.

-

Read more ...

Book protection films have many advantages: In addition to protecting against damage, the book's covers are easy to clean and resistant to a wide range of cleaning agents and solvents. The easy-to-clean and resistant to a wide range of cleaning agents and solvents. The easy-to-clean covers are a big advantage for libraries and any other location where books are handled by many people. Nevertheless, there are a few points you should consider when cleaning your wrapped books.

Cleaning book protection films

In order to prevent dust particles, small grains of sand or other particles from damaging the surface, damp cleaning is recommended for book protection films. A special cleaner for films is not necessary and conventional cleaning agents can be used. A mixture of warm water and detergent is very effective. However, very aggressive or abrasive cleaning agents are not suitable.

Disinfecting book protection films

How the book protection film can also be disinfected and not just cleaned, depends on the film.

To select the right kind of disinfectant, take into consideration which types of microorganisms are to be killed. Additionally, it is important to keep the agent's effect on the material in mind. Not every surface is compatible with all types of disinfectants. Under certain circumstances, some book protection films can be damaged by the use of certain chemical compositions.

To clean book protection films thoroughly, it is wise to disinfect them with a liquid agent. Disinfection with gases (such as ethylene oxide) and radiation (beta or gamma rays) is not possible with book protection films.

Liquid disinfectants are based on

- Ethanol

- Isopropanol

- Glycerine

- Hydrogen Peroxide

- Distilled Water

However, these components can have a negative effect on plastic, depending on their concentration, exposure time and temperature. Additionally, the reaction depends on the plastic material itself because every type of surface reacts differently to these chemicals.

Disinfecting PVC-based book protection films

Book protection films made of PVC are sensitive to ethanol and isopropanol. The result: The film becomes brittle if it repeatedly comes into contact with these substances. The two named chemicals dissolve the plasticisers and the alcohol penetrates the film, causing it to swell up. Afterwards, the film will feel sticky. However, Glycerine, hydrogen peroxide and distilled water do not harm PVC films and are therefore a better choice for disinfection.

Disinfecting PP-based book protection films

When it comes to disinfecting PP-based films, it is important to know that hydrogen peroxide can damage the surface more easily due to its oxidation effect.The other components (ethanol, isopropanol, glycerine and distilled water) do not harm the material and are a good choice.

Note: Both, PP and PVC book protection films should be cleaned or disinfected carefully, otherwise the surface will get scratches from the cleaning motion, resulting in the film’s transparency to be lost.

-

Read more ...

In many industries, products and manufacturing processes that are more sustainable is becoming more and more important. In the field of self-adhesive media, the movement towards eco-friendliness represents a major challenge. The problem is obvious: Plastic and therefore self-adhesive films are generally challenging in regards to their eco-friendliness. However, it is difficult to avoid them completely in everyday life. For example in book protection films, PVC (polyvinyl chloride) has many advantages towards other materials and is easy to work with. Nevertheless, Neschen has developed many product alternatives on the basis of PP (polypropylene) instead of PVC over the years. This way, customers can choose a suitable product depending on each individual application. Additionally, Neschen works with solvent-free acrylate adhesives and ensures that all raw materials are free of harmful additives.

But what exactly is the difference between PVC and PP?

After PE (polyethylene) and PP, PVC is the third most important polymer for plastics. PVC is divided into hard and soft PVC. Many users prefer PVC films because they are softer and more elastic and therefore easier to process. PP is recognised as an eco-friendlier alternative because it is a simply structured synthetic material and also a “by-product” of the petrol industry. This resource is put to good use in the form of protecting or mounting films.

Over the years, Neschen has developed alternatives on the basis of PP for virtually every application (digital print, protection and mounting films). PP films are a little more difficult to work with because they are less flexible. Cutting through the material is also a little more difficult than cutting through the PVC version.

Nevertheless, a lot speaks for using PP films as an alternative to PVC:

- non-toxic combustion

- byproduct of the petrol industry

- does not contaminate ground water

- virtually shrink-proof

- temperature resistant up to +100°C (212°F)

Skip to Content

- Create an Account

- Offers for you

+44 (0) 1527 853 136