-

Read more ...

New products and services, new ways of working, plus a more eco-conscious and socially responsible outlook mean print business leaders have a huge opportunity to reinvent the way they work. Print business leaders are looking to grow and adapt to meet urgent customer demands, and to develop new offerings that could help clients move in new directions.

They know they need to become more efficient, focus on costs, and improve workflow by using technology that will help them simplify and streamline processes. And many are seeking ways to become socially responsible—for the sake of their customers, their reputations and, ultimately, profit.

So, let’s look at some of these trends and try to understand what they’ll mean for your print business over the coming months and years.

How content and creativity are driving the industry transformation

With customers demanding unique ideas and more creative solutions, print businesses must step up to shape the future. Indeed, two fifths regard diversification of their large format print offering as a high priority, according to a survey from Widthwise in 2020.1

This could come from providing new products and services to existing customers, or finding innovative ways to build an additional customer base.

Interior decor is just one example. This covers many things, from fine art to durable upholstery, but the size of the opportunity is huge. Just consider that the global digitally printed wallpaper market has been predicted to grow at 23.6% annually (CAGR) until 2025, to reach a total value of $10.4 billion, according to figures from Energias Market Research.2What’s more, print businesses are dealing with customers who have unprecedented demands and expectations around content. They have witnessed the meteoric rise of content platforms such as Canva and Zazzle and have become accustomed to buying goods and services from easy-to-use e-commerce platforms that offer next-day, or even same-day, delivery. How can print businesses respond with creative solutions that provide content, ideas, and experiences to meet the demands of customers?

How intelligent automation can help print businesses work smarter

While business leaders must pay close attention to sales growth, they must also focus on customer service and profitability. A big part of that is ensuring operations run effectively, and that means reducing costs, errors, and wastage while improving productivity, workload capacity, and time to market.

According to the last published FESPA Census,3 72% of print businesses are seeing increased demand from customers for faster turnaround times, and 59% believe that customer demand for “just in time” deliveries will increase.

Increased use of automation is one way to help on both fronts. In 2020, Keypoint Intelligence4 asked print businesses to compare the share of total on-site print volume that was produced in a 100% automated workflow with their expectations for the future. The survey found that while 63% of volume was produced without any automation in 2020, that figure would drop to 36% by 2022.

Workflow and automation technology can make all the difference. It can help improve the way print businesses operate by helping them quote more accurately, negotiate better prices with suppliers, and see where cost efficiencies can be made. Plus, software and services can also enable businesses to grab new opportunities—building a digital presence to capture orders online, for instance.Making sustainability profitable for your print business

Recent HP research5 reveals that 85% of PSP customers now demand sustainable products and practices. The research is supported by the Widthwise study which showed that in 2020, 81% of PSPs regarded sustainable print solutions as “more important” than two years previously. 48% of respondents said their environmental focus for 2020 was to measure and/or reduce their carbon footprint.

This is driven by a desire to be more socially responsible, but also because of the business opportunity. Indeed, there is an urgent and growing need to find alternatives to materials such as PVC, with big brands leading the charge by making a commitment to being PVC free.

How is your print business reacting?

Accelerating change

Print businesses have been evolving for some time, and the turbulance experienced in 2020 only accelerated that change. Many are displaying resilience and creativity, and businesses that will survive and thrive will be the ones that are versatile, connected, sustainable, and safe.

HP can help you take the next step to ensure your print business has the best chance of success.

- July 2020 Widthwise Report www.imagereportsmag.co.uk/widthwise. Widthwise also did a PSP survey pre-Covid, at the beginning of 2020

- https://www.globenewswire.com/en/news-release/2019/04/23/1808076/0/en/Global-Digitally-Printed-WallpaperDPW-Market-to-Witness-a-CAGR-of-23-6-during-2019-2025.html

- FESPA Print Census Report, 2018

- https://postscript.psda.org/Full-Article/9-trends-for-print-distributors-in-2021

- https://press.hp.com/us/en/press-releases/2021/hp-drives-versatility-sustainability-new-latex.html

-

Read more ...

Easy to use, incredibly versatile, and exceptionally accurate. Keencut cutting machines improve your business. Acclaimed by signmakers, printers, and framers worldwide, Keencut is the market-leading solution for your finishing needs.

Here’s ten reasons why a Keencut cutter is the perfect choice!

- Slash production time

Keencut cutters reduce production time and increase your workflow. It’s about speeding up productivity with the reassurance of a precise, flawless finish. - Guaranteed accuracy

Keencut machines are precision calibrated and made from quality components, so unlike other manufacturers, Keencut specifies an accuracy level for every cutter and a comprehensive 5-year guarantee. - Incredibly versatile

Keencut machines cut a wide range of rigid, semi-rigid and flexible materials. And, if there is a new material we do not list, we will test it and advise on the best cutting process. - Reduced waste

Wasted materials cost money! With Keencut’s cutting accuracy, you cut precisely, reducing costly mistakes and minimising waste. - Clean cutting

Every Keencut cutter cuts and finishes without creating debris. There’s no dust to damage printer heads or create flaws in your vinyl application. Keencut cutters are regularly fitted to Applicator Tables. Just think of all that time saved on vacuuming the workshop! - Cut and finish in one action

With a Keencut cutter, you cut and finish in one action. There’s no need to deburr and no sharp edges. The cutting action is smooth and requires minimal effort. - Perfect repeatability

Keencut technology ensures accurate, repeatable cutting to produce precise, identical pieces. - Reduced staffing costs

With a Keencut cutter, an inexperienced operator can create perfect results in moments. One person can align and cut materials regardless of board size or thickness. - No power costs or lengthy maintenance

There are no additional power costs when using Keencut machines. You do not require electricity, and the maintenance is minimal. - Cut your own

With a Keencut cutter, everything is under your control. You have no delays waiting for pre-cut boards to arrive, no extra costs, or quality issues. And you get to use any offcuts.

About Keencut

Keencut designs and manufactures manual cutters for the print finishing and picture framing markets, with world-leading accuracy and reliability. Products are sold around the globe to most countries in Europe, the USA, and as far afield as Russia and Australia.

We design and manufacture our entire product range at the Keencut factory in Corby, UK. We use the finest materials and state of the art manufacturing techniques to ensure the highest quality and reliability, and our products come with a minimum five-year comprehensive guarantee plus a minimum 20-year guarantee on all rotating and sliding bearings.

With a broad range of manual cutters, Keencut meets the ever-increasing requirements of customers in the sign-making, large & small format printing, and picture framing industries. Our dedication to finding the ultimate precision engineering solution to each application means that our products have a worldwide reputation as the most accurate, reliable and easy to use.

If you are looking for precision and durability in your cutter, choose Keencut.

- Slash production time

-

Read more ...

Plotters and printers may seem similar at first sight as both produce replication artwork. The latest plotters and printers support memory cards, digital cameras, and scanners. And they’re both considered peripheral output devices, which means several computers can connect to them.

The key difference between them is that plotters deliver a much higher resolution in a format that is similar to a vector graphic (an image created with very fine lines). This means they’re ideal for producing documents that are reliable, accurate, and error-free. These documents are typically specialized high-quality drawings such as blueprints, circuit diagrams, maps, hatch patterns, etc. And for this reason, plotters are more suitable for use within architectural, engineering, and construction (AEC) industries.

A traditional printer, on the other hand, uses toner to print multiple dots of ink, or pixels, usually onto paper, which is not as clear or precise as a plotter. Generic printers also print up to 11x17, while some plotters can print to up A0, which is nearly three times larger. The size limitations of printers can cause some AEC firms to lose out on larger jobs.

Other important differences

Images produced using large format plotters can be enlarged without losing clarity or resolution, unlike generic printers that print blurry or pixelated images.

Printers can only print a single line at a time, while plotters have movable printheads that can easily draw continuous lines at the same time. Printers, in turn, print hard copies more quickly than plotters and at a lower cost.

Large format plotters can read files in DWG, CDR, AI, and other vector formats. Its software includes Adobe Illustrator, Corel, Flex, and CAD. Printers can read BMP, PDF, and JPG TIFF formats, and its software includes Photoshop and other image-editing programs.

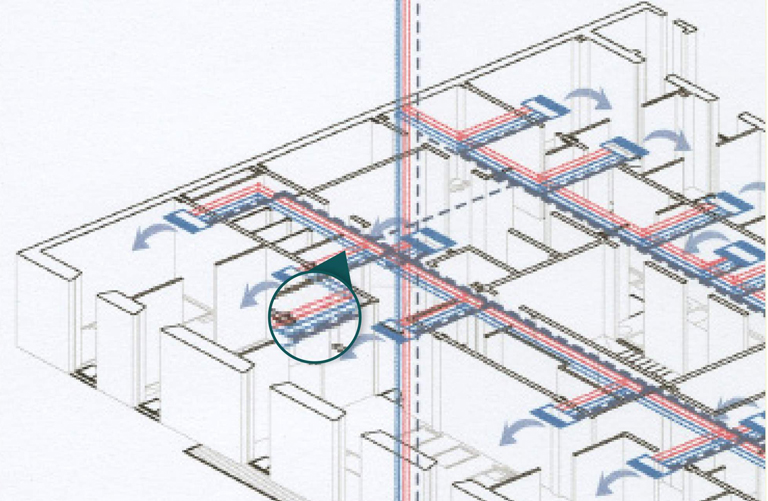

Scenario 1: Printing colour blueprints with many fine and bold lines

Colour blueprints with numerous fine and bold lines are clearly superior when printed on an 11x17 plotter that is built for these kinds of tasks.

This printout was created using the HP DesignJet T200 Plotter series, which is a unique large format plotter with print capabilities. When placed side by side with the output of a generic large format printer, it’s clear which delivers the better print quality.

The HP DesignJet T200 Plotter series is also capable of printing up to A1 - and provides fast, one-click printing of multiple files. The A3/B automatic sheet feeder accessory lets you print multi-size large format workflows without changing media input. Plus this series uses up to 95% less ink for routine maintenance.

The HP DesignJet T200 Plotter series is also one of the most sustainable large format plotters in the world, reducing carbon emissions with up to 30% recycled plastic.

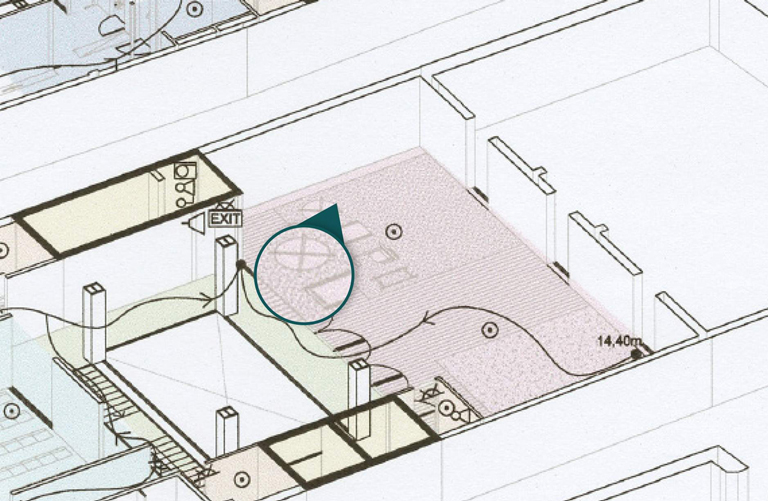

Scenario 2: Printing hatch patterns

HP’s large format printer plotters produce more accurate replication of hatch patterns and texture while generic large format printers will lose details.

The hatch pattern above was produced using the HP DesignJet T650 Plotter series. This large format printer plotter is able to print multi-size A3/B and A0/E projects automatically without having to switch the media source manually. It uses up to 95% less ink for routine maintenance than competitors and prints up to 100 additional A1/D pages per month. It also increases user productivity by printing up to two times faster, while HP Bright Office Inks plot with up to 31% more line accuracy and up to 65% more gamut. Its ability to print up to A0 size means it can meet the printing requirements of AEC companies producing larger prints and blueprints.

Scenario 3: Printing diagrams with multiple colours

As a large format printer plotter is designed for AEC purposes, it produces prints with brighter colours compared to the dull, grainy output of generic large format printers.

This output comes from the HP DesignJet T2600 Printer series. Because it can print five colors with greyscale, it delivers the highest accuracy and displays the finest details using the unique Adobe PDF Print Engine. It also easily digitizes projects with automatic scanning, user-centric quicksets, and post-editing capabilities. It empowers your workforce by allowing users to work quickly and collaboratively with easy access to shared folders for printing and scanning.

The two-in-one choice

Besides giving your office the capabilities of a large format plotter AND printer, the portfolio of 11x17 printer plotters has many other appealing features and attributes. They are among the world’s smallest yet fastest large format printer plotters. They fit your office, the way you work, and your budget. And they’re also incredibly quiet -with up to 87% less noise using the HP DesignJet T2600.

-

Read more ...

Social responsibility is a hot topic for businesses across the board. This is particularly true for the print industry, with one recent study from HP and C Space finding that 85% of print businesses that operate Latex large format printers are demanding sustainable products and practices.1

Companies of all sizes need to respond quickly, and the important thing is to see it as both a socially responsible endeavour and an economic opportunity. One that can enable print businesses to lower their costs, streamline services through more efficient, circular processes and win new business by delivering sustainable services to even the most eco-conscious customers.

Why the industry needs to pursue social responsibility

Research suggests that print businesses are keen to become more sustainable, with a study by Widthwise2 showing that in 2020 three quarters has achieved environmental accreditations, with 9% working on getting them, In addition, the major environmental focus for that year was to measure and reduce the carbon footprint for almost half of PSPs, with 16% planning to reduce or recycle in-house waste. Mean while, there is an urgent and growing need to find alternatives to materials such as PVC, whose manufacture and disposal are recognised as dangerous to the environment due to the release of harmful chemicals. Along with big brands, the print industry is responding, with many suppliers developing more eco-conscious media.

Making social responsibility profitable for your print business

While the print industry is clearly making significant inroads into sustainable practices, it’s still at the foothills when it comes to making social responsibility an economic advantage to the business. However, there are many ways that print businesses, both large and small, can make environmental practices work for them financially. Among these are reducing energy consumption by using more efficient printers. Or adopting printers that use recycled or recyclable materials and less packaging, and reflect this in their cost. Improving in-house energy generation through solar power may also be worth pursuing. Or using dashboard tools to closely measure metrics in order to identify and drive efficiencies and track ROI so the business can make more informed buying decisions. In addition, developing environmentally friendly print services for eco-conscious customers can be a competitive differentiator. For example, printing facilities can have their sustainability practices certified through accreditations such as the US-based Sustainable Green Printing Partnership (SGP).3

Why it's imperative to improve employee safety

Employee safety is, and should be, an important aspect of social responsibility and something that businesses should make every effort to de-risk. The most common types of print industry accidents are due to manual handling (27%), slips and trips (22%), and machinery (22%). So, as well as making print services more environmentally friendly, PSPs also need to improve employee safety by reducing risk, providing training, and avoiding manual handling where possible in favour of digital and mechanical automation. Where solvents and UV can irritate the skin, leading to dermatitis, businesses should investigate less harmful chemicals and water-based inks, which fundamentally provide healthier print production without trading off performance. Governments have put strict guidelines in place for the printing industry. These regulations are formulated to safeguard the lawful rights and interests of printing operators as well as social and public interests. Furthermore, labour organisations and councils across the globe ensure that the legislation passed for worker safety isn’t overlooked. And by safeguarding employees and developing a protective and healthy environment, PSPs will increase staff safety, satisfaction, and retention, which will ultimately benefit the business as a whole.

Rising to the challenge of change

Print businesses are under pressure to change. But they have proven themselves resilient over recent years: able to adapt to the market, transform digitally, and adopt sustainable practices. The next few years will be critical in continuing the good work that’s already been done in order to create a bright future anchored in environmental, societal, and economic sustainability.

-

Read more ...

Print businesses are making it a high priority to diversify their large format print offering as customers increasingly demand unique ideas, more creative solutions, and new content. However, business leaders are aware something needs to be done, but many don’t know where to start.

The solution is to begin the journey of transformation so they can offer more competitive services that will shape the future. Not only will it help businesses serve existing customers better, it will enable them to enter new markets, innovate new print solutions, find fresh revenue opportunities, and scale up their offerings into the future.

Transformation is definitely on the minds of many print businesses. Two fifths regard diversification of their large format print offering as a high priority, according to a survey from Widthwise in 2020.1 This could come from providing new products and services to existing customers or finding innovative ways to build an additional customer base. There are many ways to evolve.Why now is the time to transform

Demand for wide format printers is expected to rise over the next few years. One estimate from Report Linker2 valued the global market at $3.4 billion in 2020, projecting it to reach $4 billion by 2027.

This, of course, follows the economic effect of the pandemic which depressed demand and revenues for many print businesses as offline retail opportunities were scaled down, conferences and events were cancelled, and travel was limited. In fact, revenue for the printing services industry declined an estimated 12.2% in 2020 as businesses cut back on advertising and marketing expenditures.3

However, the print world is an ever-changing one, and print businesses must stay sharp. The way to secure new business in the years ahead is to innovate and pivot your offerings to meet market demand, while also delivering reliable and efficient services.Innovating in new areas could benefit your business

The future holds many opportunities for PSPs to innovate, interior decor being a great example. This covers many things, from fine art to durable upholstery, but the size of the opportunity is massive. Just consider that the global digitally printed wallpaper market has been predicted to grow at 23.6% annually (CAGR) until 2025, to reach a total value of $10.4 billion, according to figures from Energias Market Research.4

Printed packaging and labels is another growth area, driven by the increasing use of printed corrugated material in retail-ready packaging as well as in e-commerce, according to market report publisher Smithers.5 The consultancy estimates that the total value for printed packaging and labels reached $431.6 billion in 2020 and will continue to expand at a CAGR of 2.6% to reach $491.1 billion in 2025.

How content requirements are expanding the possibilities

In addition, print businesses are dealing with customers who have unprecedented demands and expectations around content. They have witnessed the meteoric rise of web-based content creation platforms such as Canva and Zazzle. These enable consumers to remotely design and print professional posters and brochures and a full range of merchandise, using predefined and customizable graphics and designs.

What’s more, consumers have become accustomed to buying goods and services from easy-to-use e-commerce platforms that offer next-day, or even same-day, delivery. While providing stiff competition, it also opens up the possibilities for print businesses to expand their service portfolios through online and e-commerce.

Online platforms’ broad reach also enables businesses to explore new geographies and customer demographics. And if you don’t have the resources to expand your own digital content services, you could partner with an existing online provider to enter new web and mobile markets.Diversification and industry transformation mark the road forward

Transformation and diversification will mean different things to different businesses. For some, it will mean trying new initiative and channels to enter different markets with the latest offerings. For others it will involve exploring new materials, form factors or products. And for others still, it could mean a foray into the world of e-commerce and content services.

Whatever industry transformation means to you, now is the time to explore your options. The demand is there, the technologies and solutions exist. All that’s left is for you to adopt a growth mindset, explore the possibilities, and boldly carve a new path for your business.- www.imagereportsmag.co.uk/widthwise

- www.reportlinker.com/p03915683/Global-Wide-Format-Printers-Industry.html

- www.ibisworld.com/united-states/market-research-reports/printing-services-industry/

- www.globenewswire.com/en/news-release/2019/04/23/1808076/0/en/Global-Digitally-Printed-Wallpaper-DPW-Market-toWitness-a-CAGR-of-23-6-during-2019-2025.html

- www.smithers.com/resources/2020/nov/printed-paperboard-covid19-ecommerce-and-beyond

-

Read more ...

The quality of the consumables determines everything from the cost of each print, through how environmentally sustainable you are right up to how much downtime you experience on any day. The quality of print is determined by many things: the speed and accuracy of the print engine, the intelligence of the software running that engine, the quality of the media and so on. But one thing which is often neglected, is the quality of the printhead.

What to look for in a professional-grade ink cartridge

Cartridge composition plays a crucial part in determining how environmentally sustainable your printer is. The cartridge should be made of materials with as small an environmental footprint as possible. It should be easy to dispose of. That means not just that the material from which the cartridge is made should be easy to recycle. It must also mean that the inks contained in the cartridge can be handled and disposed of without expensive special procedures.

Alongside the quality of the ink itself, a key determinant of the accuracy, fidelity and vivacity of your print jobs is the science behind the printhead. The printhead must be able to deposit ink droplets with the highest degree of accuracy possible. The printer should be able to keep it clean and working at peak efficiency. And it should do this, while also minimizing the requirement for manual intervention and downtime.

How HP Latex consumables get the job done

The new HP Latex 700 and HP Latex 800 Printer series are designed specifically to meet these challenges. Instead of conventional print cartridges, made of plastic, these large-format printers use recyclable HP Eco-Carton ink cartridges. The outer cardboard of which these innovative consumables are made can easily be recycled at any local cardboard and paper recycling programs.

By replacing plastic cartridges with the new HP Eco-carton ink cartridge, the amount of plastic used in each consumable is reduced by up to 80% and the CO2 associated with that cartridge by up to 66%. And where HP printers and supplies do still contain plastics, these are often recycled plastics, created with post-consumer electronics, soda bottles, UL-validated ocean bound plastics, coat hangers, and empty Original HP ink cartridges.

The inner linings, containing the ink, can be disposed of through the HP Planet Partners program. And because water-based HP Latex Inks contain no hazardous air pollutants (HAPs), this not only makes handling easier, it also makes disposal simple and stress free. Taken together, these design attributes mean you send zero supplies-related content to landfill when you use these HP printers. And HP Latex inks deliver vivid colours with striking contrasts.

These inks are delivered through an HP Latex Printhead. These are capable of delivering inks to the page in droplets as small as 10-picoliters. A picoliter is a trillionth of a liter. With such tiny ink droplets, delivered with pin-point accuracy thanks to the precision of the software and engineering in the print systems, print jobs are clear, sharp and vibrant.

-

Read more ...

In an industry continually pressed for time, an efficient and reliable large format printer plotter that can translate CAD drawings, technical drawings, and plans onto paper quickly and on-demand is crucial. From an IT perspective, the requirements are a little different. The top concerns among IT teams are:

- Connectivity capabilities

- Document and data security

- Ease of use

- Print speed

With so many large format brands and models in the market, how do you choose the plotter or printer plotter that meets the needs of IT teams, creatives, and engineers alike? Here are some important things to consider

Secured hardware protection

Large format printers and plotters are as much targets as your workstation. In fact, unsecured printers can open the door to hackers or malicious code infiltrating your organization.

A secure boot process is a key component of large format printer security. This embedded feature automatically validates the integrity of its BIOS code. Validation failure triggers a restart, and a saved “golden copy” of the BIOS is then loaded.

Large format printer security includes protecting sensitive data. Secure user authentication controls help to ensure that only individuals with the proper credentials can access the large format printer and its confidential documents

Whitelisting is another essential security component. It ensures firmware integrity by using a digital signature to verify that only authentic and authorized code, solutions, and third-party files are loaded into the large format printer’s memory. Similarly, a restart will be triggered when an unauthorised file is detected to prevent execution of a potential malware exploit.

Get everyone on the same page

Mobility in large format printing and scanning is essential for smooth collaboration. Wi-Fi enabled large format printers eliminate the need for users to have access to a router or a local network. And that makes it possible for anyone with their own smartphones, laptops, or tablets to print their large format drawings.

Projects can be delayed with stakeholders when the latest designs or technical drawings can’t access the large format printer in your office or out in the field. Providing everyone with access to the same tools helps to make sure that projects can progress, especially when many stakeholders are involved.

Keep track of spending

The frenetic pace of AEC offices generates a significant number of technical documents as teams constantly rework their designs. Such activity can accumulate costs as quickly as it depletes resources.

Data tracking and reporting software is the first thing IT teams need if they want to manage and oversee large format printing activity and spending. Ideally, this should be able to produce detailed and easy-to-read reports as well. These reports can provide insights on a particular user, department, project, or individual jobs. Depending on what is important to your team, you can craft your reports based on key weekly, monthly, or quarterly metrics.

Less is more

Indeed, less IS more when it comes to your large format printer’s user interface. Confusing or cluttered user panels present problems and a constant source of frustration for many users. Large format printer plotters that are designed with the end user in mind enable greater self-sufficiency and are less reliant on the IT help deck to resolve menial tasks. A product with intuitive functionality also means less training or assistance for first-time use.

Minimise delays with large format hard copies

No project is safe from delays. Downtime can be caused by the remote or inaccessible field sites, or harsh weather. Connectivity in these areas can also be problematic, which is why it’s useful to have hard copies in these situations.

Today, large format printer plotters are more cost-effective than ever. And they deliver documents with higher resolution and color accuracy than previous generation printer plotters. More importantly, they are evolving to help IT departments do more - for a lot less.

Keep these 5 points in mind when you’re choosing a fast, reliable, and easy-to-use large format printer plotter to boost the productivity of your IT teams, creatives, and engineers.

-

Read more ...

Getting your AutoCAD drawings onto paper can sometimes be tricky if you are working with complex files or unfamiliar printers. This article walks you through the process of printing from AutoCAD to a large format printer or plotter and how to convert CAD drawings to PDF.

Printing AutoCAD drawings to a large format printer / plotter

If your computer is connected to a large format printer or plotter configured to print AutoCAD drawings, printing is relatively straightforward. All you need to do is input the following:

- If you’re printing the entire large format drawing or just part of it

- The paper size you’re printing on

- The scale of the large format print

- The line weights assigned to different objects

Plot dialog box settings

The Plot dialog box may appear in standard or expanded mode. To open the expanded Plot dialog box, click the arrow icon in the bottom right corner.

To print a CAD drawing from a layout, just right-click on the Layout tab of the drawing that you want to print and select Plot. (Note: If you are in Model view, go to View and switch to the desired layout.) This will bring up the Plot dialog box.

Printer/Plotter

This dropdown list contains the printing devices that have been configured to work with AutoCAD. Choose the large format printer plotter you’ll be using to print your AutoCAD drawing. The Properties button to the right of the dropdown list contains settings that have been preconfigured by your computer.

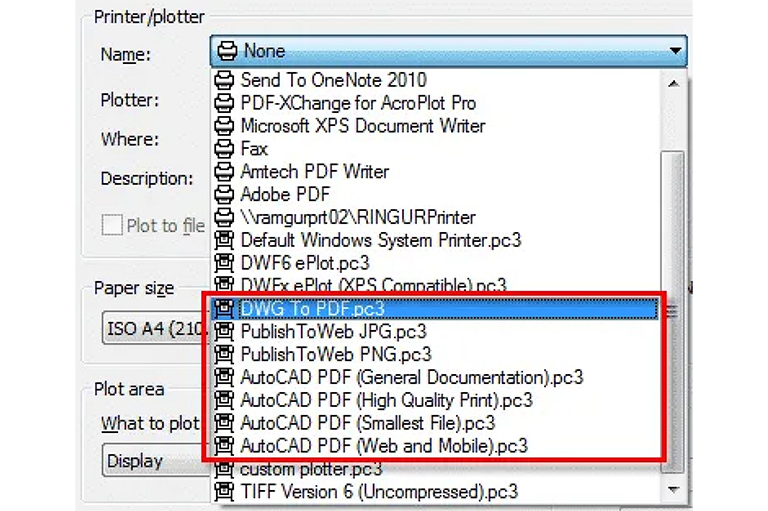

The printer/plotter dropdown list also contains various PDF printing options, as seen in the image below. We’ll cover the different AutoCAD-to-PDF options later in this guide.

The plot to file button saves your large format drawing as a .plt file so that it can be printed later, on another computer, or by a print production service.

Paper Size, Number of Copies

Make sure you’ve selected the right paper size and have the matching paper ready in your printer. You can also choose the number of copies to print.

Plot Area

This is where you must decide what you want to print from your drawing. If you have yet to set the visibility of the layers you want to print or hide, you’ll need to do that first. Next, click on the dropdown list to find five options: Display, Extents, Limits, View, and Window. Assuming you have checked the “Fit to paper” option, this is what will be printed from your choice of plot area:

- Display - Print what is on the screen, including any blank areas

- Extents - Fill the print area with all visible objects in the drawing

- Limits - Print everything that lies within the limits grid set in your large format drawing. If your drawing contains Layouts, then you’ll see a Layout option instead.

- View - Print a view that you have saved with the large format drawing. If there are no saved views this option will not appear.

- Window - This allows you to drag a window around any part of your large format drawing that you want to print.

To see what your large format print will look like using different Plot Area options, simply click the Preview button at the bottom left of the Plot dialog box.

Plot Scale

If you want to print a scale from AutoCAD rather than fitting it to your paper, uncheck the “Fit to paper” option. You can then select either a predefined scale from the dropdown list or enter a custom scale.

Plot Offset

This allows you to either center the plot on the plot area instead of starting from the origin or input a custom amount of space to offset the plot.

The expanded plot dialog box

Clicking the arrow icon in the bottom right corner opens the expanded Plot dialog box, which contains some additional settings.

- Plot Style Table: Allows you to plot using different plot styles available on your computer

- Shaded Viewport Options: Select the shade mode for printing 3D views

- Plot Options: These are applied to layouts

- Drawing Orientation: Toggle the paper orientation

How to convert a CAD drawing to PDF

As AEC firms move toward remote work and digital transformation, digital file sharing is slowly becoming the norm. Instead of printing physical copies of your CAD drawings, you may find yourself converting your DWG files to PDF instead. Not only are PDF drawings more easily readable by users without AutoCAD, but they can preserve layer data and other properties at your desired file quality.

What’s confusing is that AutoCAD offers three different ways to convert your CAD drawing to PDF. Let’s look at the differences between each method and which one is best for your purposes.

Plot to PDF

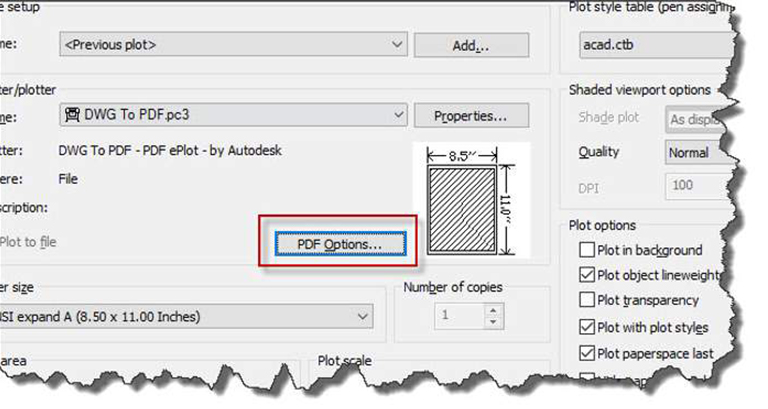

This uses the Plot dialog box described earlier in this blog. Depending on which edition of AutoCAD you’re using, you should see options like DWG to PDF.pc3 or AutoCAD PDF (General Documentation).pc3. A PDF Options button should appear, allowing you to set the resolution for the output PDF drawing

Export to PDF

The export function can be accessed via the menu or by typing EPDF on the command line. This is useful when you’re in layout view. Using the Export command, you can plot all layouts of your drawing into a single PDF file.

Publish to PDF

The Publish command (synonymous with the Batch Plot command in your toolbar/menu) is helpful if you’re creating multi-page PDFs of selected layers. To open the Publish dialog, type PUBLISH on the command line.

The sheets list will display all open drawings by default, but you can add or remove drawings to match the content you want printed. Then click the “Publish Options” button and make sure that Type is set as Multi-sheet file.

Finally, if you are using Sheet Sets, you can publish directly from the Sheet Set Manager by right-clicking the Sheet Set tree menu. This enables consistent publishing standards using predetermined settings that have been added by a manager or project owner.

Determining line weights for your drawings

Obtaining precise line weights can be a little tricky when printing AutoCAD drawings with a printer and in PDF format, especially since standards vary across different professions within the AEC industry. If the object lineweights in your drawing differ from what is plotted, type LWDISPLAY in the command line and type ON to toggle on the lineweight display. Then click the following:

- In the Plot dialog, uncheck Scale lineweights and Plot object lineweights

- Type PROPERTIES in the command line and, under the Lineweight dropdown, select ByLayer; this helps to ensure that object lineweights are controlled by the layer

- Use a higher resolution with plotting to PDF

- In your PDF viewer (such as Adobe Reader), go to Preferences > Page Display: uncheck Smooth line art and Enhance thin lines

- As a last resort, you can change the lineweight of various objects to the desired thickness. However, this isn’t recommended for files and projects that involve a lot of collaboration, or if you are doing production printing on a client’s file.

Tips to ensure print precision from your CAD drawings

Make sure colours and patterns are distinct

When preparing your large format drawings, review them at a smaller scale and check if differentiating patterns, textures, and supporting text are sufficiently distinct. This can prevent confusion between different construction materials and construction delays.

Print using HPGL/2 drivers

Accuracy in your CAD drawings is essential. To ensure accuracy, HP developed the HPGL (and thereafter, HPGL/2) printer description language. Unlike raster-based driver outputs, HPGL/2 ensures 100% dimensional accuracy regardless of the printer’s output resolution. A CAD drawing printed on a 300dpi printer will have the same size and lineweights as the same drawing printed on a 1200dpi printer.

HPGL/2 also produces plot files that are exceptionally compact, with a constant code size whether you print in Draft, Normal, or Best mode. This saves AEC professionals from having to export multiple plot files for different printers and use cases.

Choose the right printer for your needs

If you’re printing complex drawings and your current large format printer is unable to accurately print the colours and details in your design, consider outsourcing that particular print job or investing in a large format printer upgrade for suitable large format printers for use with AutoCAD please check out our extensive portfolio of CAD printers from HP.

-

Read more ...

To stay ahead in a rapidly evolving market, print service providers need to find ways to win more high-value jobs and grow their premium client base. The market for large-format printing is growing. A survey by IDC, from March 2021, found the sector growing by 12% in the third quarter of 2020 (the most recent figures available) 1. Another recent study predicted annual growth for the segment of 3.2% a year, every year between now and 2026 2.

But that doesn’t mean that print service providers (PSPs) can just sit back and relax. As the market booms, so does competition. Vendors that are most agile in adapting to changing market conditions — whether that’s the impact of lockdown or customer demand for new formats and finishes — will win market share from those that don’t.

One of the most noticeable trends is the increasing demand for high-value-add print products, particularly those which incorporate personalization, new technologies and media, or both. Between now and 2025, the market for personalised digital printing — which not only allows for customisation but also uses innovations such as mild solvents and less-harmful chemicals - is predicted to grow by 6.45% a year, faster than the market as a whole 3What does this emphasis on new technologies, new formats and greater digitisation mean for PSPs and how can they win in a rapidly evolving marketplace?

Use technology to be more versatile

Using new intelligent print-management solutions is a vital part of becoming more adaptable and being able to take on higher-value jobs. The best print-management solutions give you an overview of all the large-format printers in your stable, allowing you to see from one dashboard things such as printer status, ink levels, job queues and more.

Another important part of any strategy to win more high-value jobs, and to grow premium print services as a proportion of your total work, is being able to take on jobs that require a high-quality finish, effects that aren’t possible with standard print technology, and specialised media.

The new HP Latex 700 and HP Latex 800 Printer series deliver all these capabilities and more. Using new HP white inks, these printers produce vivid signage, add a background layer to CYM images for backlighting, improve colouring, make edges sharper and more. Making the switch to a high-value white latex ink printer means you move into higher-value jobs, particularly when taking on jobs which specifically require a higher print quality.

By allowing you to print with white and coloured inks on a broad range of transparent and coloured media, the new latex printers enable you to take on the following print applications, using white ink and on transparent or coloured media:

- Outdoor signs

- Vinyl wraps

- Professional stickers

- Window graphics

- Posters

- High-volume signage

Not only does this allow you to take on more higher-margin jobs from direct clients, but it also has the potential to make you a valuable outsource partner for PSPs who don’t have the same advanced latex printing facilities. According to recent research by Keypoint Intelligence, PSPs outsource 46% of high-value, high-complexity jobs 4. Most of these outsourced high-value applications end-up being printed on HP Latex printers. By choosing the right technology, you can win some of that business and reduce risk.

Footnotes

- https://uk.finance.yahoo.com/news/idc-industrial-printer-tracker-shows-133000539.html

- https://www.largeformatreview.com/business/business-news/covid-19-heralds-decade-of-disruption-for-print-say-smithers

- https://www.globenewswire.com/news-release/2020/12/21/2148429/0/en/Digital-Printing-Market-Growth-Trends-Forecasts-2020-2025.html

- Based on a research conducted by Keypoint Intelligence July 2020 and commissioned by HP, over 100 print service providers across the U.S., Europe, and India.

-

Read more ...

Considering the versatility of today’s large-format printers, architect, engineering, and construction AEC professionals can gain access not just to fast, convenient, high-quality printing, but a slew of exciting applications - beyond technical blueprints and plans. Now you can use 24-inch large-format printers for marketing and promotional products, flyers, posters, and more.

If you’re in the business of AEC, it’s not a question of IF you should purchase a large-format printer plotter for your business. Rather, it’s which one is right for you? The purpose of this blog is to help you identify key features that you should be evaluated in the decision-making process.

Capabilities to Consider

- Simplicity – 24-inch printing that’s quick to install and even easier to use

- Connectivity – convenient connectivity options that fit the way you work

- Quality – High-resolution prints with clear, accurate results across applications

- Speed – Speeds that keep the business continually moving forward

Technical printing for the non-tech-savvy user

AECs have enough to think about and do without worrying about how to operate their large-format printer. That’s why you want to look for a 24-inch printer that is just as easy to operate as any home or office printer. HP’s 24-inch DesignJet printers - from the T200 and T600 series through to our stylish STUDIO printers - are designed to deliver incredible simplicity.

A recent review of the T200 series described the product as a “relief” to set up, taking only 10 minutes. And all of our 24-inch printers include HP Click software, a simple print job tool that enables you to print high-quality drawings, posters, and more with just one click. Users can even print multiple files at once. Another benefit of HP’s 24-inch large format printer plotters is the HP Smart app, which you can connect to your desktop, PC, and mobile device to manage your printer from anywhere.

Connect in more ways than one

Another factor that plays into your printing experience is connectivity. You want to make sure that you choose a large-format solution that provides multiple connectivity options—like Wi-Fi 802.11, Hi-Speed USB 2.0, and Gigabit Ethernet—that allow you to connect with and use your printer in a way that makes the best sense for your business and work style. For example, you may want your printer positioned in an out-of-the-way spot in your office, in which case, wireless capabilities are an important consideration.

Quality that communicates effectively and reflects your professionalism

It goes without saying that high-quality output is essential. Whether you’re promoting your business with marketing materials or sharing drawings with n important client, every large-format print, poster or blueprint has got to look good—that means clear, sharp text, fine line quality, and vibrant and accurate colors with every print. Resolution is a key consideration. And it’s important to note that all of HP’s 24-inch printers deliver 2400 x 1200 dpi resolution, including our entry T200 series, so top quality with HP is never-ever-a question.

Print at the speed of business

While speed might not be one of the top considerations for a 24-inch printer, you don’t ever want you large-format printer to slow you down. You also want to make sure that the speeds you expect to get don’t come at a sacrifice. Keep in mind that speed can vary depending on image, paper type, and resolution settings.

That’s why you want a large-format printer that keeps pace with the speed of business. And with HP, that is always a consideration. For example, the HP DesignJet T650 prints 24-inch wide projects in just 26 seconds - two large-format prints per minute - without impacting quality. Our entry DesignJet T210 delivers one large-format print in 45 seconds (at the default setting), which is a decent speed for this class; and - for businesses printing low-to-moderate volumes - it might just be perfect for your needs.

Other things to think about

Printing costs: Ink isn’t cheap. And when you’re thinking about the cost of printing in large-format, you’re definitely going to want to consider operating costs - and the price of supplies. One thing to note with HP DesignJet ink cartridges is that our entire 24-inch portfolio uses 95% less ink compared to common printers.

Media handling: Consider what types of documents you’ll be printing. Different printers offer a range of different media handling options from rolls to sheets - and different sized prints up to 24-inches. Select the media sizes and capabilities that best suit your business needs.

Your style: While printer features are important, so is your brand and the message your printer conveys. For design-savvy offices, the look of your large-format printer might be the deal breaker. That’s why we’ve put a lot of thought into the ID of our 24-inch HP DesignJet STUDIO Printers, which come in wood and steel finishes, to create the impression you’re after.

Don’t take our word for it. This is your printer, and it should meet your needs. We invite you to do your own research, but make sure to check out HP’s 24-inch large-format portfolio—including the HP DesignJet T200 Printer series, HP DesignJet T600 Printer series, and HP DesignJet STUDIO printers.

Skip to Content

- Create an Account

- Offers for you

+44 (0) 1527 853 136