-

Read more ...

Summa nv, a leading company of high-end cutting plotters and finishing systems, has developed a new in-house software platform to support its product range: GoSuite. The first software module within this GoSuite platform is called GoProduce. The software is bound to facilitate the operator’s work on the F Series flatbed and secure optimum rentability at the customer, partner, and installer production sites. The GoProduce software is ready for immediate release and implementation worldwide.

Advance with the right software

Flatbed cutters are the customer’s hardware of choice when they need to get to market fast. With this speed ever-increasing, the software needs to be up to par to make sure the hardware can keep a more than steady pace at the smallest error margin.

With the F Series as the fastest growing series in the Summa range, Summa selected this series as the first one to be accompanied with software to match. Instead of optimising or tailoring existing solutions, Summa opted to develop the new software platform entirely in-house.

GoProduce offers the following functionalities:

- Flexible and tailored import of files to ensure a smooth print and cut workflow integration

- Extensive material database which is able to automatically select the ideal tool and its settings based on the material

- Integrated tutorials for direct support, also available on Youtube

- Registration of square or round marks, supporting all RIPs and PDF formats & many more…

To secure an easy integration and implementation worldwide, the Summa development team made sure the software has:

- A modern look and feel with an intuitive interface and easy navigation

- Straightforward action sets for fast automated production

- Smart options for fast routing and quick problem fixing

- A tailorable and extensive material database

- Workflows and functions defined and customisable to the customer’s needs

Plug and play

The software was designed to be plug and play specifically, without any need for hardware installation. Users simply install the drivers, activate their subscription online and start operating. Geert Pierloot, Product Manager at Summa, explains: “When business is booming, there is no time for extensive training, so we wanted to keep the software as intuitive as possible so it could be implemented quickly and used immediately. Throughout March, we’re having training demonstrations and webinars planned for our dealer network and will be posting YouTube tutorials regularly so people can make the most of the functionalities. The beta tests went smoothly, and users are excited about the user experience and positive results. We’re eager to get the market’s feedback on GoProduce.”

GoProduce for the F Series is intended to make life easier on the operator, by facilitating workflows via action sets. A quick implementation will secure immediate operability enabling any operator to maximise the potential of his F Series cutting and finishing systems.

Legendary performance meets future-proofed profitability

Wim Maes, Executive Member of the Board at Summa, reflects on the importance of GoProduce for the market: “Summa is expanding its product range and is venturing into new markets. We’re convinced software is the efficiency differentiator for companies to become even more productive. So, when we researched on how to grow our solutions’ portfolio with software, we realised we had the in-house expertise to start afresh and provide our customers with the consistent quality and customer service they expect from Summa. We’re proud to say we can now fully tailor our software to our hardware to ensure our customers get to be as efficient and productive as possible.”

“GoProduce is but the first step in the future direction of cutting and finishing. We aim to stay a frontrunner, by making sure software and hardware are fully aligned for the best profitability and operational stability for any customer and operator in the large format, signage and textile markets. These software advances will future-proof the legendary performance our customers attribute to our solutions.”.

-

Read more ...

Contex, the world leader in large format scanning, today introduces two new models to the HD Ultra X scanner series. The series now includes 36 and 42 inch models, completing the range of scanning solutions for Contex’s newest line of premium scanners. Introduced in 2018 to rave reviews from the scanning community, the HD Ultra X scanner series, which also includes a 60 inch model, reigns as the market’s fastest and widest scanner series available. The scanner series outperforms the competition in colour matching and image scanning quality, while exceeding environmental standards. The scanner series also boasts numerous productivity-boosting capabilities to accelerate the scanning workflow, while delivering long-term value and a quick ROI. All scanners in the HD Ultra X series are immediately available from distributors worldwide.

“Our customers are thrilled with the capabilities of the HD Ultra X scanners, and the new models give them even more options to suit their requirements,” comments Jacob Bendix, CCO and VP of Global Sales and Marketing. “Productivity, improved workflow, and colour matching have been the center of our attention, and our customers can instantly benefit from these advancements the HD Ultra X scanner series.”

HD Ultra X scanner series expanded

The HD Ultra X series uses CCD technology for the best quality images available in the market today. Whether scanning 36, 42, or 60 inches wide, customers can capture originals at an unprecedented 17.8 ips. The common platform also gives customers the same results from each scanner model.

The scanner series includes several unique features and productivity boosters, including true size detection and instant-ON capabilities, which cut valuable seconds from production time. A throttle buffer control also eliminates scanner pauses, allowing operators to continuously feed documents without waiting for scanned data to be processed.

The HD Ultra X series boasts the fastest data transfer of any scanner on the market, made possible by the GB Ethernet xDTR2.5 and USB 3.0 SuperSpeed xDTR3 data transfer technologies.

Exclusive technologies for the most advanced image quality

The advanced technology in the Contex HD Ultra X scanner series offers customers several exclusive imaging advantages, including the highest colour-rendering index (CRI). The scanners are equipped with Contex Perfect Light, which uses the latest LED technology combined with specially developed diffusion filters.

Sharp scans are achieved by Contex’s exclusive lens spherical correction technology and accuracy lens enhancement (ALE), which minimizes optical distortion. Each scanner model in the the HD Ultra X series is equipped with X-Rite ICC colour technology and Fujifilm camera lenses, which deliver greater depth of focus — 0.3 inches — and CCD optics of up to 1200 dpi. The depth of focus allows users to capture documents of all types — especially thick, delicate, or with irregularities - with ease.

Intuitive scanning advancements

With just the press of a lever, Contex’s Optimal Thickness Adjustment Control (OTAC) enables users to quickly adjust the HD Ultra X to the required paper thickness. Feather mode also protects delicate originals and extra-thin documents.

A speed-matched roller system ensures fast and easy document loading and eliminates skewing. Operators can choose between center and side loading, or use the adjustable paper guide for smaller documents.

The scanner’s static-free, touchless glass system and steel anti-static feed table also minimize friction, while reducing maintenance costs over time from worn scanner glass.

Exceeding environmental standards

The HD Ultra X scanner series exceeds Energy Star consumption standards and is RoHS compliant.

Additionally, the LED light source, guaranteed to last the scanner’s lifetime, saves energy by automatically turning off in between scans. Instant-ON scanning capabilities also allows operators to simply load and scan originals, without requiring the scanner to warm-up.

HD Ultra X scanner series availability

The HD Ultra X scanners are available as stand-alone (Contex AIO optional) or in a ScanStation Pro configuration, which includes a stand, touchscreen monitor, and Nextimage REPRO software (Contex AIO optional). The HD Ultra X scanners can be networked to any leading printer.

About Contex

As the world's largest developer and producer of large format imaging solutions, Contex leads the market with innovative technology and advanced scan and copy software applications. Sold worldwide in more than 90 countries, Contex solutions are recognized in a wide range of industries for reliability, value, high performance, and superb image quality.

-

Read more ...

MakerBot, the pioneer of desktop 3D printing, introduces a new category for the professional segment with the launch of Method, the first performance 3D printer. Performance 3D Printing bridges the gap between desktop and industrial 3D printing by bringing features that were previously only available on industrial 3D printers to professionals at a significantly lower cost. Method leverages industrial technologies and expertise from Stratasys® (NASDAQ: SSYS) and combines it with the accessibility and ease of use for which MakerBot is known.

Industrial technologies on the MakerBot Method 3D printer include a Circulating Heated Chamber, Dual Performance Extruders, Precision PVA Water Soluble Supports, Dry-Sealed Material Bays, and an Ultra-Rigid Metal Frame. Method also includes built-in sensors and automation features that are designed to provide users with a seamless experience. The printer’s industrial features control the 3D printing process to deliver a high level of precision, reliability, and dimensional accuracy at an accessible price. This technological breakthrough defines the new Performance 3D Printing category.

“In an age of disruption, businesses are under pressure to innovate and bring products to market faster. Current desktop 3D printers derive their DNA from hobbyist 3D printers and are insufficient for many applications in the professional segment,” said Nadav Goshen, MakerBot CEO. “We believe that Method is the next step in helping organisations adopt 3D printing at a larger scale. Method provides a breakthrough in 3D printing that enables industrial designers and mechanical engineers to innovate faster and become more agile. It is built for professionals who need immediate access to a 3D printer that can deliver industrial performance to accelerate their design cycles. Method is developed to bring industrial technologies into an accessible platform, breaking the price-performance barrier and redefining rapid prototyping in the process.”

Method is designed to deliver industrial reliability and precision by carefully controlling every aspect of the 3D print environment, resulting in repeatable and consistent parts with ± 0.2 mm dimensional accuracy1 as well as vertical layer uniformity, and cylindricity. Until now, this level of precision has been limited to industrial-grade 3D printers. The dual extrusion system found in Method combined with water-soluble PVA provides a superior surface finish, and enables unlimited design freedom and unrestricted geometries, such as complex overhangs without scarring.

Method allows users to turn their CAD files to parts faster by providing a seamless and reliable workflow without tinkering, up to 2X faster print speeds than desktop 3D printers2. Method offers out-of-the-box deployment and a hassle-free guided setup, making it easy to install and use. Method also includes automated maintenance procedures and support to ensure a smooth and seamless user experience. Method delivers industrial-level performance at one-third of the first-year cost of ownership of an entry-level industrial 3D printer. With Method, teams can reduce design risks by testing and validating prototypes with accuracy early and often, minimizing potential cost overruns later in production. It is also designed to provide an elevated level of speed and control into product design cycles while reducing production costs – helping businesses bring products to market faster.

INDUSTRIAL RELIABILITY AND PRECISION

From concept validation to functional part performance, Method is created to deliver consistent print results that match design dimensions.

- The Circulating Heated Chamber controls the temperature and quality of every layer. In providing full active heat immersion during the entire duration of the print, Method allows printed materials to cool at a controlled rate, providing higher dimensional accuracy while improving layer adhesion and part strength

- Dual Performance Extruders are built for high-speed printing without compromising part accuracy. A dual-drive gear system grips the material securely while a powerful 19:1 gear ratio provides up to 3X the push force of a typical desktop 3D printer. This allows Method to provide a consistent feed of material into the hot end to produce consistent geometry. The new lengthened thermal core is up to 50% longer than a standard desktop hot end to enable faster extrusion rates and, allowing for smooth extrusion throughout its high-speed movements and accelerations.

- Precision PVA Dissolvable Supports enable fast and easy support removal without compromising part design or dimensional accuracy. Water-soluble PVA provides unrestricted geometric freedom and superior print quality and surface finish without the need for harsh solvents of industrial 3D printers or manual labor of removing breakaway supports.

- Dry-Sealed Material Bays form a seal to keep filament material pristine and reduce moisture absorption. A suite of built-in sensors monitors humidity and alerts users of any changes to the environment - a feature previously only available in industrial 3D printers. This feature is especially crucial for water-soluble PVA, which quickly absorbs moisture when left in the open with devastating consequences on print quality.

- MakerBot Materials for Method are manufactured to exacting diameter and quality specifications. Shipped in a vacuum-sealed metalized polyester bag, quality can be preserved right up until opening. MakerBot offers two categories of materials for use with Method: Precision and Specialty. Precision Materials are extensively tested by MakerBot for the highest reliability and measurably accurate parts and include MakerBot Tough, MakerBot PLA, and MakerBot PVA. Specialty Materials are for users looking for materials with advanced properties to push the limits of what's possible. These materials provide basic print performance and can require additional workflow steps to print successfully. The first material on the platform is PETG, one of the most widely used polymers with excellent engineering properties, with more to follow.

- The Ultra-Rigid Metal Frame runs the full length of the Method body to offset flexing. Less flexing means more consistent prints with better part accuracy and fewer failures.

FASTER, BETTER 3D PRINTING

Method makes industrial 3D printing technologies accessible to individual designers and engineers. Advanced workflow features turn Method into an everyday tool that accelerates the agile design process. Users can turn their CAD files to parts faster and print up to 2X faster than desktop 3D printers.

- The Smart Spool provides valuable information, including type, color, and amount of material remaining via an RFID chip directly to MakerBot Print, while desiccant in the spool maintains a low moisture level inside the drawer bay.

- The 5” Capacitive Touchscreen provides the latest status updates of current print jobs and allows users to navigate the menus in the most intuitive way.

- MakerBot Print Software easily integrates with 25 of the most popular CAD programs to allow designers and engineers to design with what they know best. For easy collaboration, teams can also save 3D files as projects and share them via the native Cloud Management platform. Method’s built-in onboard camera also allows users to monitor their print progress remotely with MakerBot Print or the MakerBot Mobile app.

- The Spring Steel Build Plate provides true flatness for unyielding part accuracy and enables the printed part to pop off the plate

The MakerBot Method 3D printer has been tested by MakerBot for over 220,0003 hours of system reliability, subsystem, and print quality testing.

The MakerBot Method 3D Printer has a starting price of £5,999. Shipping of Method is expected to begin in Q1 2019. Pre-orders are now available. To learn more about the MakerBot Method 3D printer, visit makerbot.com/Method.

MakerBot also has dedicated business offerings that are created to reduce downtime and keep teams moving. To learn more about Method for Business, visit makerbot.com/Method-for-Business.

ABOUT MAKERBOT

MakerBot, a subsidiary of Stratasys Ltd. (Nasdaq: SSYS), is a global leader in the 3D printing industry. We help create the innovators of today and the businesses and learning institutions of the future. Founded in 2009 in Brooklyn, NY, MakerBot strives to redefine the standards for 3D printing for reliability, accessibility, precision, and ease-of-use. Through this dedication, MakerBot has one of the largest install bases in the industry and also runs Thingiverse, the largest 3D printing community in the world. We believe there's an innovator in everyone, so we make the 3D printing tools that make your ideas matter. Discover innovation with MakerBot 3D printing.

NOTE REGARDING FORWARD-LOOKING STATEMENTS

The statements in this press release relating to Stratasys’ and/or MakerBot's beliefs regarding the benefits consumers will experience from the MakerBot Method 3D Printer and its features, and MakerBot Materials for Method, Stratasys’ and MakerBot's expectation on the timing of shipping the MakerBot Method 3D Printer and MakerBot Materials for Method, are forward-looking statements reflecting management's current expectations and beliefs. These forward-looking statements are based on current information that is, by its nature, subject to rapid and even abrupt change. Due to risks and uncertainties associated with Stratasys' and MakerBot's business, actual results could differ materially from those projected or implied by these forward-looking statements. These risks and uncertainties include, but are not limited to: the risk that consumers will not perceive the benefits of the MakerBot Method 3D Printer and MakerBot Materials for Method to be the same as Stratasys and MakerBot do; the risk that unforeseen technical difficulties will delay the shipping of the MakerBot Method 3D Printer and MakerBot Materials for Method; and other risk factors set forth under the caption “Risk Factors” in Stratasys' most recent Annual Report on Form 20-F, filed with the Securities and Exchange Commission (SEC) on February 28, 2018. Stratasys (or MakerBot) is under no obligation (and expressly disclaims any obligation) to update or alter its forward-looking statements, whether as a result of new information, future events or otherwise, except as otherwise required by the rules and regulations of the SEC.

-

Read more ...

Summa, a leading manufacturer of high-end cutting plotters, proudly presents two new sizes of their finishing flatbed systems. The F3232 and F3220 are based on the proven technology of the Summa F Series. Through the expansion of the flatbed series, Summa strives to improve the synergy with the large format digital printer market and to meet the needs of their customers. The new flatbeds are expected to be ready for shipment in February / April 2019.

Fully equipped for the textile market

Within the world of large format digital printing, most common sizes of textile printers are equipped with a working width of 3.2 m to be able to print large rolls of textiles. Both new Summa flatbed cutters, the F3232 and F3220, also cover a working width of 3.2 m, making them the ideal companion to process common, popular print sizes with utmost ease and accuracy.

The matching working area sizes of the textile printer and Summa’s new finishing cutter sizes will lead to a print and cut workflow, fitting seamlessly into each other and offering endless solutions to the flourishing textile market.

Geert Pierloot, Summa’s Product Marketing Manager, points out: “The new sizes of flatbed systems enrich Summa's platform with advanced finishing solutions, especially within the textile industry. Together with the recent launch of a more powerful High Torque Rotary Module (HT RM), both the F3232 and F3220 are the ideal workhorses to serve the textile market in the processing of all sorts of mesh fabrics, flags, and banners."

Processing large board material in a flash

However, not only the textile market will benefit from Summa's two new sizes of flatbed finishing systems. Then both flatbed sizes are also perfectly suited to cut the increasingly popular board sizes of 3 m x 2 m. Additionally, the F3232 with its working area of 3.2 m x 3.2 m, has the inclusive feature: Summa’s Tandem Mode. This feature will increase productivity of the customer’s workflow by using the front zones and rear zones alternately. The Tandem Mode will be most beneficial when processing board sizes of 1.5 m x 3 m. All existing tools and models within the F Series gamut are designed to fit each size of the flatbed range, the F3232 and F3220 sizes inclusive. This ensures the highest versatility to process all kinds of material and offer numerous high-end solutions to the sign making, textile, and digital print industries.

About Summa

Every day, for more than 3 decades, Summa delivers the world's highest-quality vinyl and contour cutters, finishing flatbeds and laser cutters without compromise. Summa provides cutting edge solutions for the printing, signage, display, apparel and packaging industries. Summa’s global headquarters is located in Gistel, Belgium.

-

Read more ...

Following high demand from the market, Innova are pleased to announce the European launch of Photo Art by Pictorico

For many years, photographers in Europe have striven to keep the magic of darkroom printing alive. Using photographs taken on a digital camera, they found the perfect partner for printing digital inkjet negatives to expose in the darkroom: Pictorico film. To ensure that photographers can always get their hands on their favourite inkjet film, Innova Art has partnered with Pictorico to launch the Innova Photo Art by Pictorico co-branded product range.

“The partnership between Innova and Pictorico is a perfect match,” says Innova Art Sales Manager, James Cannone. “The Pictorico brand is built on a philosophy of creating high quality output media for a broad range of inkjet printers, so that every photographer can produce great quality prints. Something we are also passionate about at Innova. We are excited to be able to build a long term relationship on these shared values, and, we know that photographers throughout Europe will benefit from it.”

Photo Art by Pictorico launches in early 2019 with two products:

Pictorico Pro OHP Transparency Film 174gsm (IPF 120), available in A4 and A3+, 20 sheet packs as well as 17”, 24”, 36”, 42” and 59” wide rolls in 20m lengths. This translucent film is compatible with all inkjet printers. Suitable for printing digital negatives for use with traditional photographic processes, or producing high density negatives for silk screen exposure. Pictorico Pro OHP Transparency Film 174gsm (IPF 120) can also be used to create eye catching backlit displays.

Pictorico Ultra Premium OHP Transparency Film 184gsm (IPF 121), available in A4 and A3+, 20 sheet packs as well as 13”, 17” and 24” wide rolls in 20m lengths. Compatible with all inkjet printers this translucent film has a higher ink load capacity than its sister product. This makes the Pictorico Ultra Premium OHP Transparency Film 184gsm (IPF 121) a great option for producing digital negatives where ultra dense blacks are required.

Photo Art by Pictorico will be available to purchase from European Innova resellers in the first quarter of 2019.

About Innova

More than paper

In addition to an award-winning range of digital inkjet media, Innova also offers innovative display solutions, custom converting solutions and is consistently at the forefront of development for new and exciting digital print media. While traditional manufacturers focus on tweaking the same types of products they have had for years, Innova is forward looking and strives to listen to today's marketplace and deliver innovative solutions for digital inkjet printing and display applications.

Excellence through innovation

Established just as the 21st century started, Innova is not bound by century old thinking and paradigms. We use modern flexible approaches to this dynamic industry, with an emphasis on innovation bounded by a desire to deliver quality products and value to our distribution partners as well as the end consumer. Don't let the relatively young age of the company fool you. Innova's management team includes pioneers of the industry who have been creating new digital papers since the beginning of the inkjet revolution in the 1980's. Our right-sized structure allows us to be nimble enough to react to changing market needs while also assuring our partners a close-knit relationship with our leadership team.

Our partnership approach to global manufacturing and distribution allows us to leverage the strengths of our own resources with those of others. This synergy not only results in enhanced product designs and improved time to market but also localised packaging, converting and warehousing to easily react to regional supply requirements.

A 21st century company with 21st century solutions

We are also 100% committed to the world around us and strive to maintain a relationship with ethical supply chains. For more information about our environmental commitment and the archival standards of Innova papers please visit our website at www.innovaart.com

-

Read more ...

Onyx Graphics, Inc., the market leader in powerful and reliable wide-format and grand-format RIP and print workflow software, is committed to aiding customer success by providing 24/7 resources for customers around the globe. With ongoing technological advancements, Onyx Graphics provides an extensive portfolio of resources that are designed to accommodate its worldwide customers anywhere, anytime.

With an immense global network and countless end users, Onyx Graphics continues to create new and viable resources with frequent content updates, across the entire ONYX portfolio of resources. They include myonyx, an online gateway containing smart business tools, product help, video tutorials, knowledge-based articles, and white papers to help keep ONYX users’ businesses running smoothly;ONYX TV, the official ONYX YouTube channel with quick tips, how-to videos and ONYX news; ONYX Professional Services and Training, web-based and hands-on ONYX certification workshops to further customer knowledge on ONYX software; and ONYX Advantage, the company’s subscription-based support and maintenance program with easy access to online help and a dedicated technical support hotline service center. Customers can access these web-based resources to stay up-to-date with the latest news from Onyx Graphics including announcements on product updates and all available learning opportunities.

myonyx: Online resources keep businesses running smoothly

With myonyx, Onyx Graphics continues to strengthen the communication between the company and its customers by providing ONYX users with a wide range of tools necessary to make smart business decisions. As an all-encompassing online portal, myonyx provides end users with round-the-clock access to product downloads, product help, product updates, user guides, white papers, knowledge base papers and tutorials on-demand, to help keep their business running smoothly while they focus on running day-to-day operations. ONYX users can access the myonyx portal using their own personal credentials located at www.onyxgfx.com/login/.

ONYX TV: Knowledge-sharing videos anywhere, anytime

ONYX TV is the official video headquarters for ONYX award-winning RIP and workflow software. Industry experts will guide users through free instructional videos featuring in-depth information across the entire ONYX product portfolio – including videos for the new ONYX 18 software – such as how to meet customer brand colour needs, setting baselines for process control, knowing when to calibrate printers before printing, and match standards such as G7 and Fogra. In addition, users have complete access to the entire set of ONYX product portfolio playlists. By subscribing to ONYX TV, users gain immediate access to the latest Onyx Graphics news through notifications, alerting the subscriber of new content. An ONYX TV subscription is available through www.youtube.com/OnyxGraphics.

ONYX Professional Services and Training maximise investment

ONYX Professional Services and Training programs give users the knowledge they need to save both time and money through a collection of renowned workshops. Taught by ONYX industry experts, customers can choose web-based or hands-on workshop certification training on ONYX 18 software. Each session provides an in-depth working knowledge of ONYX software that gives customers a competitive advantage by learning how to maximise investment. In addition to the ONYX Certified Technician and ONYX Certified Operator workshops, the release of ONYX 18 software has launched two new workshops in colour management and profiling. Customers interested in obtaining more information on how to enroll in certified operator, technician, or colour management training can inquire through PSW or by visiting www.onyxgfx.com/support/training.

ONYX Advantage keeps RIP and workflow software current, offers access to ColorCheck

The ONYX Advantage program is a cost-effective way to keep RIP and print workflow software current. It provides an easy way to get all the latest features to avoid any last-minute need to update, setting a project back. Users receive instant access to ONYX software upgrades, versions, and releases as well as the hundreds of new and existing drivers for printers, cutters and colour devices. With the purchase of ONYX Advantage, contract holders can have peace of mind knowing that their investment is secure with access to an expansive library of on-demand videos covering product training and application support.

Highlights of ONYX Advantage include:

- Access to global technical support team

- Access to customer support telephone hotline

- ONYX support online access with myonyx

- Access to new version releases

- Free hardware key replacement

- Special access to product whitepapers

With an ONYX Advantage Gold subscription, users gain exclusive access to new product features and product functionalities including ONYX Hub business intelligence software and the new ColorCheck feature when using ONYX Thrive software. More information on the benefits of obtaining an ONYX Advantage subscription can be found at www.onyxgfx.com/support/onyx-advantage-2

About Onyx Graphics, Inc.

Leading the market since 1989, Onyx Graphics is dedicated to helping customers increase productivity, reduce costs, and gain a competitive edge with superior print and colour quality. Its passion for delivering superb colour led to the development of ONYX Color, Onyx Graphics’ own colour engine optimised specifically for large format inkjet printing. Innovative, productive, and satisfied customers around the globe help motivate the company to continually develop and enhance its leading-edge technologies. Global channel partnerships and longstanding relationships with printer manufacturers position Onyx Graphics as a market leader in powerful, reliable, large format printing workflow software.

-

Read more ...

The FineArt industry will see a new paper that elevates FineArt printing to a new level. As the inventor and pioneer of genuine artist papers for inkjet printing, Hahnemühle fulfils the wish of many photographers to include a FineArt paper made of 100% cotton in the Digital FineArt Collection – this time with a metallic effect. The evenly shimmering metallic effect corresponds perfectly to the haptic of a real artists’ paper from the benchmarking Photo Rag®-family and makes Photo Rag® Metallic unique on the market.

The premium inkjet coating ensures bright colours, deep blacks and perfect colour and detail reproduction. The sophisticated silver metallic effect underscores the image and makes motifs with metallic elements, reflections, ice and glass, architecture and landscape shots, as well as black and white photographs with high-contrast tones, shine. Depending on the incidence of light, the metallic effect glimmers stronger and gives the printed motifs a unique liveliness.

Photographer Kitfox Valentín is delighted by the new Photo Rag® Metallic: “In my pictures, I dive deep into the world of finest details to accentuate and illuminate my compositions. With my picture of the series ‘Beatific / Caustic’, I attach great importance to the fact that the print exudes the iridescent mica or the rich shine of the composition. Photo Rag® Metallic radiates the bold, shimmering quality brilliantly. By pairing ‘Beatific / Caustic’ with the new Photo Rag® Metallic Paper, I was able to deliver high-quality FineArt prints to the world without compromising the image.”

The 340 gsm paper is made of 100% cotton and has no optical brighteners. Of course, Photo Rag® Metallic, like all Hahnemühle papers in the Digital FineArt Collection, is free of acid and lignin and meets the highest requirements for aging resistance. With different roll and sheet sizes, photographers can choose from a wide range of options. Users get the best printing results with our Hahnemühle ICC profiles. The ICC profiles are available for download on our website.

About Hahnemühle

Hahnemühle is considered the inventor of Digital FineArt papers for inkjet printing. As a pioneer, the oldest German artist paper manufactory has been refining its real artist papers for photography and art reproductions for more than 15 years.

The papers – manufactured for more than 430 years with characteristic craftsmanship – receive a special coating, without influencing the noble haptics of the papers. This inkjet coating allows prints with pin-sharp details, in both rich colour and deep blacks. All papers have excellent aging resistance. The Hahnemühle Digital FineArt Collection offers more than 20 different papers, while the Hahnemühle Photo Range is comprised of eight papers.

Hahnemühle has a worldwide reputation as a ‘brand of the century’ among artists, photographers, museums, galleries and collectors.

Headquartered in Dassel, Southern Lower Saxony; with offices in the United Kingdom, France, USA and China; the company employs approximately 200 people worldwide.

-

Read more ...

Even though the phrase "time is money" is almost as old as time itself, it still applies to small and big companies of today. Summa, value your time and will continue researching every way to improve your workflow. Summa makes your dream come true and enables you to divide your job time almost in half thanks to the release of the G-Performance mode. This mode is specifically designed to enhance the speed/performance of digital finishing operations on the S Class 2 roll cutters up to 40%, which will save you precious time to spend on other things.

Transform your S Class 2 cutter into a lean, mean, even faster-cutting machine than before with the G-Performance, no matter whether it be a cutter with tangential or drag knife technology or our smallest or largest cutter in the product range. However, speed is not the only advantage you will benefit from. Your S Class 2 cutter will be able to read registration marks, to achieve a perfect cut, even with print deformations, at an ever faster pace!

No matter how wide the substrate and/or machine, the advantages of the G-Performance will definitely show in production times. The G-Performance mode is available as free unlock on new machines (2018). However, even S Class 2 cutters, built before 2018, can experience the full benefits of the G-Performance mode as well. Especially within large industrial environments, this G-performance mode will prove its worth and give your overall workflow a serious boost.

Make your dream a reality and release the G-Performance mode on your S Class 2 vinyl and contour cutter! Unlock your boost extension at www.summa.eu/g-performance!

Not convinced? Have a look at a side by side comparison of two S Class 2 cutters, one with and one without the G-Performance mode.

Why stop there?

And while we're at it, Summa released even more features (for free!) to enhance the finishing experience with your Summa S Class 2 cutters. Check it out!

Short Load

This new functionality on the S Class 2 cutters ensures less material will be forwarded, so possible material obstructions are avoided. The fixed size of the autoload of the media is 80 cm. Not only does the short load mode makes sure the material will not touch the floor or be hindered by obstructions, it also guarantees less waste of material, which contributes to the overall user-friendliness, the environment (less waste=less pollution) and your wallet!

Dog Ear Function

Thanks to the updated intelligence on the Summa S2 Series, dog ears (pleated corners) in the substrates will be avoided during loading. Before, the cutting head would immediately start on the right side of the media during loading, which could then lead to these pleated corners. With the dog ear function, the head will first position itself on top of the media during loading and will position itself on the right side afterwards. As a result, damaging the product will be avoided and a clean cut can be yours to admire!

OPOS XY2

OPOS has the unique ability to register multiple marks along a job. With the OPOS XY2 function also the additional XY line at the end of the job will be read now, which will lead to more compensation possibilities in deformation and even more contour cut accuracy than before, especially when cutting large jobs. No restriction, only unsurpassed accuracy, and impeccable precision!

The new S Class 2 screensaver is more informative, which will enhance user-friendliness to the fullest. Moreover, instead of the Summa logo, tips will be shown to make sure ultimate efficiency will be reached during the job.

-

Read more ...

Today, Onyx Graphics, Inc., announced global availability of ONYX 18, the newest version release of the company’s award-winning wide- and grand-format software that includes new colour technologies for colour accuracy, consistency, and conformance to standards such as G7 and Fogra that print service providers can prove to their customers.

ONYX 18 – covering the entire product portfolio of ONYX solutions including ONYX Thrive print workflow; and ONYX ProductionHouse, ONYX PosterShop and ONYX RIPCenter RIP software – is now available to all ONYX Advantage customers by requesting a key update and to all other customers for immediate purchase. The ONYX Advantage subscription program gives ONYX software users a quick and easy way to keep their software current and secure their investment. Customers that are not ONYX Advantage subscribers should contact PSW Paper & Print for more information.

“ONYX 18 represents the next generation of wide-format print software capabilities,” said Bryan Manwaring, Director of Product Marketing at Onyx Graphics. “The improvements really raise the bar in giving print service providers the ability to validate colour, match standards and maintain consistency to get the best possible output.”

Previewed at the International Sign Expo in Orlando, March 22-24 and formally announced at FESPA Global Print Expo in Berlin, May 21-23, ONYX 18 software gained immediate recognition upon its launch from the European Digital Press when it was honoured with the 2018 EDP Award for Best Colour Management software.

Key features

The latest release of ONYX 18 gives users a new colour experience, while bringing consistency, reliability, and power to a print environment. Highlights of ONYX 18 include:

- ONYX Color, the industry-leading colour engine, includes new core enhancements for improved black ink combinations that give increased shadow detail, texture and definition, as well as increased saturation of reds and oranges without compromising ink savings. Textile and soft signage application benefit especially from these enhancements.

- ColorCheck, a new process control tool set that enables print service providers to guarantee colour accuracy to their customers as well as ensure consistency of output across devices over time.

- ColorCheck also ensures conformance to standards including G7 and Fogra as well as baseline testing for process control and in-product indicators for printer recalibration.

- PosterColor 2.0, a technology first introduced to the industry by Onyx Graphics, uses next-generation smart rendering intent to boost saturation of solid colours for added ‘pop’ across all image types.

- AccuBoost, new for ONYX 18, is an iterative ICC profiling technique for pinpoint accuracy of ICC profiles.

- The latest Adobe PDF Print Engine (APPE 4.8), accelerates processing for patterns and soft masks with super-fast algorithms for rendering complex file types resulting in big performance gains.

About Onyx Graphics, Inc.

Leading the market since 1989, Onyx Graphics is dedicated to helping customers increase productivity, reduce costs, and gain a competitive edge with superior print and colour quality. Its passion for delivering superb colour led to the development of ONYX Color, Onyx Graphics’ own colour engine optimised specifically for large format inkjet printing. Innovative, productive, and satisfied customers around the globe help motivate the company to continually develop and enhance its leading-edge technologies. Global channel partnerships and longstanding relationships with printer manufacturers position Onyx Graphics as a market leader in powerful, reliable, large format printing workflow software.

For more information, visit www.onyxgfx.com.

-

Read more ...

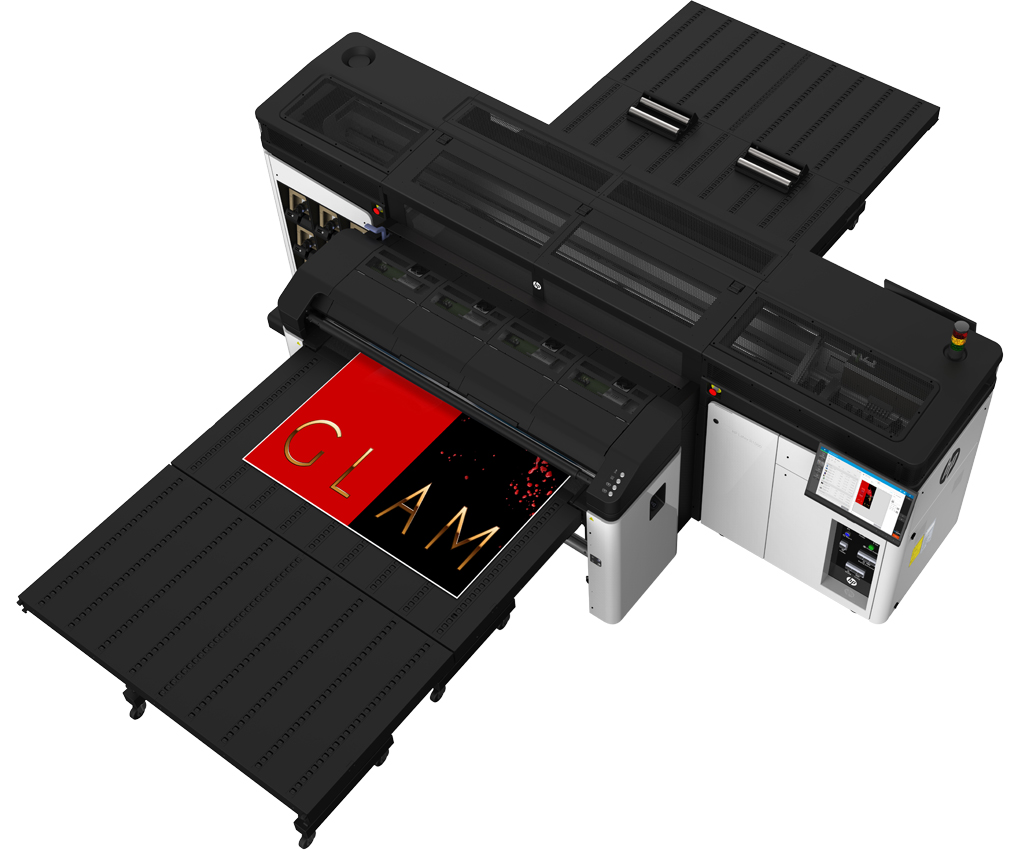

Today, HP Inc. expanded its hybrid HP Latex R Printer Series with the R1000 Printer for rigid and flexible printing. Designed for a variety of hybrid applications including signage and displays, the growing portfolio offers choice, value, and versatility while featuring innovative technologies including HP Latex Rigid Printing Technology and HP Latex White Ink.

“Print service providers are looking at new ways to increase production and expand applications by investing in innovative print technologies such as rigid and white ink to embrace all the possibilities of print,” said Joan Pérez Pericot, General Manager, HP Large Format Graphics Business, HP Inc. “The new introduction to our HP Latex R Printer Series delivers a versatile and innovative print solution for medium-sized businesses to unlock print opportunities and drive growth.”

The current portfolio includes the HP Latex R2000 Printer, designed for large-signage printer service providers (PSP) who require workflow efficiency and sustained production. With the debut of the HP Latex R1000 Printer, HP is adding depth to offer maximum value in one device. Designed for growing businesses with investment and space constraints, the versatile printer offers a single set of inks for a wide range of flexible and rigid media including applications for retail, outdoor signage, window graphics, events and exhibitions, and decorations.

The new printer comes with three liter-ink cartridges, compared to the larger model with five liters, and is designed to accommodate materials up to 1.64 meters/64 inches wide and up to 5 cm/2-inches thick while the R2000 prints up to 2.5-meters/98-inches wide and up to 5-cm/2-inches thick.

The HP Latex R1000 enables:

- High image quality and vibrant colours: HP Thermal Inkjet Printheads and redesigned HP Latex Inks achieve vibrant colour gamut on rigid while preserving media gloss and feel with no smell

- Printing in white without barriers: HP Latex White Ink delivers the glossiest white on transparent and colored media and achieves no waste between white print jobs. The removable HP Thermal Inkjet Printheads can be stored in an offline rotating chamber and automatic maintenance makes white like any other color, including automatic recirculation and nozzle checks

- Durability and versatility: HP Latex Overcoat adds durable and flexible water-based ink for high adhesion and scratch resistance while lower curing temperatures allow for wide media versatility

- Efficiency: Productive belt workflow enables customers to handle print peaks in-house and meet short deadlines with up to 57 square meters per hour (614 square feet per hour) with up to 60 kg/150lb rolls for flexible printing

- Smarter printing: Proactive and preventive services via HP Smart Services maximize uptime and helps avoid costly operating mistakes with automatic maintenance, smart vacuum, and assisted loading

About HP

HP Inc. creates technology that makes life better for everyone, everywhere. Through our portfolio of printers, PCs, mobile devices, solutions, and services, we engineer experiences that amaze. More information about HP Inc. is available at http://www.hp.com.

Forward-Looking Statements

This news release contains forward-looking statements that involve risks, uncertainties and assumptions. If the risks or uncertainties ever materialize or the assumptions prove incorrect, the results of HP Inc. and its consolidated subsidiaries (“HP”) may differ materially from those expressed or implied by such forward-looking statements and assumptions.

All statements other than statements of historical fact are statements that could be deemed forward-looking statements, including but not limited to any projections of net revenue, margins, expenses, effective tax rates, net earnings, net earnings per share, cash flows, benefit plan funding, deferred tax assets, share repurchases, currency exchange rates or other financial items; any projections of the amount, timing or impact of cost savings or restructuring and other charges; any statements of the plans, strategies and objectives of management for future operations, including the execution of restructuring plans and any resulting cost savings, revenue or profitability improvements; any statements concerning the expected development, performance, market share or competitive performance relating to products or services; any statements regarding current or future macroeconomic trends or events and the impact of those trends and events on HP and its financial performance; any statements regarding pending investigations, claims or disputes; any statements of expectation or belief; and any statements of assumptions underlying any of the foregoing.

Risks, uncertainties and assumptions include the need to address the many challenges facing HP’s businesses; the competitive pressures faced by HP’s businesses; risks associated with executing HP’s strategy; the impact of macroeconomic and geopolitical trends and events; the need to manage third-party suppliers and the distribution of HP’s products and the delivery of HP’s services effectively; the protection of HP’s intellectual property assets, including intellectual property licensed from third parties; risks associated with HP’s international operations; the development and transition of new products and services and the enhancement of existing products and services to meet customer needs and respond to emerging technological trends; the execution and performance of contracts by HP and its suppliers, customers, clients and partners; the hiring and retention of key employees; integration and other risks associated with business combination and investment transactions; the results of the restructuring plans, including estimates and assumptions related to the cost (including any possible disruption of HP’s business) and the anticipated benefits of the restructuring plans; the resolution of pending investigations, claims and disputes; and other risks that are described in HP’s Annual Report on Form 10-K for the fiscal year ended October 31, 2015, HP’s Quarterly Reports on Form 10-Q for the fiscal quarters ended January 31, 2016, April 30, 2016 and July 31, 2016, and HP’s other filings with the Securities and Exchange Commission. HP assumes no obligation and does not intend to update these forward-looking statements. HP’s Investor Relations website at http://www.hp.com/investor/home contains a significant amount of information about HP, including financial and other information for investors. HP encourages investors to visit its website from time to time, as information is updated and new information is posted.

Skip to Content

- Create an Account

- Offers for you

+44 (0) 1527 853 136