-

Read more ...

Onyx Graphics, Inc., a pioneer in wide-format digital printing solutions and RIP software development, is set to preview ONYX 24 and unveil the much-anticipated ONYX Sync at FESPA 2024. Version 24 introduces features such as automated multi-layer printing, seamless mobile device integration, and advanced print quality assurance. These innovations continually demonstrate the company's commitment and capability in powering the next generation of automated printing solutions for print operators and businesses worldwide.

Introducing ONYX 24: Elevating Print Workflow Efficiency

ONYX 24, the company’s latest release in RIP software, introduces major optimisations that address key industry challenges in print automation and efficiency. Developed with feedback from industry professionals, version 24 achieved major breakthroughs, including automated multi-layer preparation for spot colours and effects, mobile spectrophotometer calibration, and embedded workflows for colour verification.

This release marks a significant leap forward, with end-to-end automation that transforms integrated print management. Key technical highlights include:

- Easy Multi-Layer Printing: Achieves effortless multi-layer printing through automated generation of layers based on spot colours, varnish, or other special printing effects. This feature streamlines complex file preparation by eliminating manual separation of elements across layers, saving valuable time while ensuring quality.

- Wireless Support for NIX Spectro Devices: Introducing native support for the NIX Spectro 2 and Spectro L spectrophotometers via Bluetooth. This new wireless connectivity powers the next generation of colour measurement, enabling wireless reading and calibration at an affordable price.

- Colour Accuracy Verification: Users can now add a ColorCheck Baseline Swatch to newly created profiles to verify the accuracy of future prints. This is achieved by incorporating a ColorCheck Strip at the time of profile generation, subsequently establishing a quality baseline for printers. When future print jobs utilise this process control feature, the same patches can be measured in order to verify that the prints continue to adhere to colour quality benchmarks, allowing for the detection of drift over time and to prevent errors.

"ONYX 24 marks a major milestone in our commitment to address practical challenges faced by the printing industry," said Matt Crawford, CEO of Onyx Graphics, Inc. "With this release, we're fully ready to roll out our most innovative RIP solutions to our European customers, empowering our users with the tools they need for unparalleled efficiency and success.”

ONYX Sync: The Future of Print Shop Automation

ONYX Sync is the latest REST API developed to enable print service providers (PSPs) to grow and automate their businesses. Our solution enables print shops to fully streamline and align their print production processes with various business tools, and to connect ONYX Thrive with users’ existing business management software to enhance workflow efficiency and productivity.

This API integration empowers print shops to eliminate manual tasks, minimise operational errors, and conserve essential production time, resulting in advantages such as:

- Real-time production feedback and status updates through an intuitive API.

- Seamless integration with existing business management software, eliminating manual intervention.

- Automated job submission and management tools for increased efficiency and scalability.

- Enhanced communication and job status notifications for better customer service.

“ONYX Sync drives tremendous sustainability gains through automated production efficiency,” said Crawford. “The seamless integration with ONYX Thrive optimizes workflows to minimize waste, create circular material usage, and provide robust analytics for carbon and environmental impact management. By embracing API and IoT technologies to reduce print resource intensity, we firmly believe ONYX Sync creates a greener model for the future.”

About Onyx Graphics, Inc.

Leading the market since 1989, Onyx Graphics is dedicated to helping customers increase productivity, reduce costs, and gain a competitive edge with superior software solutions for the print industry. Innovative, productive, and delighted customers around the globe help motivate the company to develop and enhance its leading-edge technologies. Global channel partnerships and longstanding relationships with printer manufacturers position Onyx Graphics as a market leader in powerful, reliable, large-format printing workflow and print business software solutions.

-

Read more ...

Sustainability is becoming a growing priority for businesses due to an increased desire for eco-conscious practices and a growing list of regulations related to businesses' environmental impact. Research shows that environmental impact will be the top business priority for businesses in the US and UK by 2025, with over 50% of companies aiming to be net zero by 2060. HP has long been an organisation that leads by example when creating sustainable printing solutions.

The development of the new DesignJet T850 and T950 printer series is our latest contribution to reducing our environmental footprint in the printing industry and helping our clients meet their sustainability goals. In this article, we'll explore the technology that enables these new printers that improved print quality while reducing the ecological impact of printing practices.

Presenting the DesignJet T850 and T950 Printers

The HP DesignJet T850 and T950 printers are designed for ease and efficiency. Each model can boost productivity and maximise agility while promoting sustainable printing practices. With an array of eco-friendly features that range from energy and ink-efficient design to the use of recycled materials, these new printer series are laying the foundation for the sustainable printing solutions of the future.

Key Sustainability Features of the New DesignJet Printer Series

The HP DesignJet T850 and T950 printers are equipped with innovative technologies that optimise ink and energy consumption and usage. AEC professionals minimise waste and reduce business costs when adopting these technologies. Some of the key sustainability features in the new DesignJet printer series include:

More Printer Energy Efficiency

Sustainable printing solutions directly address energy efficiency related to:

- The impact of the ink or toner used to print

- Cartridges

- The energy required to run the printer

Energy use during inactivity and reduced printer efficiency can result in increased energy consumption during the printing process.

Auto-schedule capabilities in the HP DesignJet T850 and T950 series enable users to reduce energy usage during idle time by scheduling printer on/off usage. Also, auto-scheduling for ink maintenance routines addresses energy consumption related to lost printer efficiency that occurs without regular maintenance.

Eco-Conscious Materials

Investing in sustainable printing solutions is a vital step in decreasing the environmental footprint of your business. The DesignJet T850 and T950 series printers are made with at least 40% recycled plastics and recyclable supplies. The compact build of these printers and high-quality materials further reduce waste by extending the time to replacement. They also decrease the overall amount of non-recyclable waste.

Reduced Environmental Impact

Alongside the many energy-efficient features, the HP DesignJet T850 and T950 series printers are built with a variety of productivity-enhancing components that can help AEC professionals reduce their overall environmental impact in the printing process.

For instance, the T850 series uses HP Flex Tech Inks that allow users to achieve high-quality CAD and renders across print sizes for fewer reprints due to low quality. The T850 and T950 series printers enable users to manage the device and print from virtually anywhere with the use of the HP App. This capability reduces the need for excess travel related to printing requirements.

Reduced Ink Usage

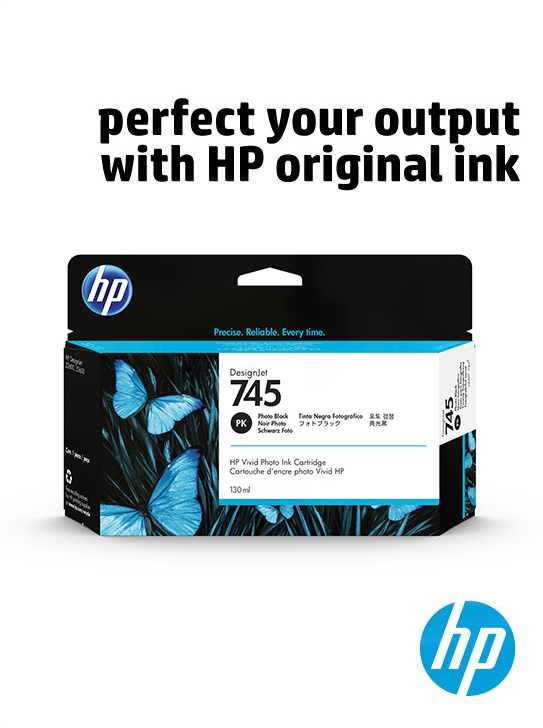

The cost of printer ink is one of the most prohibitive costs of using and maintaining a large format printer. Reducing ink waste with sustainable printing inks can help AEC professionals cut costs and decrease their ecological footprint. Designed for easy printing with minimal distractions, the T850 DesignJet series printers feature 130/300-mL ink cartridges that require fewer ink interventions. Larger cartridge sizes also reduce raw materials used in the production of cartridges, cost of transport, and related waste.

The T850 and T950 series printers also allow users to automate ink maintenance routines. This option reduces printer inefficiencies that result in wasted ink due to repeat printings when errors occur.

Minimal Printing Waste

Minimising your business's printing requirements is the most effective way to save energy and reduce printing waste. HP's newest printers use several features to help reduce printing waste.

- The T850 series uses HP Flex Tech inks for high-quality images that meet your needs with fewer reprints, reducing paper and ink waste.

- T850 and T950 printers allow users to avoid reprinting with print previews.

- Designed for productivity, the T950 series helps users avoid damage to finished prints with a stacker that holds up to 40 pages flat for easy collection.

Higher Cost Savings

The features of the HP DesignJet T850 and T950 series printers work together to help AEC professionals cut costs in many ways. From the features that reduce energy and ink waste to those that improve print quality, HP's new sustainable printing solutions help businesses reduce printing costs.

Efficiency and productivity features help businesses cut costs further by reducing manual tasks and saving time. For instance, T850 printers feature an integrated input tray that eliminates the need to change from roll to sheets manually. T950 printers use integrated input and output trays that keep pages sorted by size. It can seamlessly print all A3 jobs without interruptions.

What Makes HP's T850/T950 Series Sustainable?

Designed with energy conservation and reduced ink waste in mind, the T850 and T950 series have specific features that optimise sustainability.

Easier Ink Replacement and Maintenance

Sustainable printing inks reduce raw material usage, wasted ink, and general printing waste. From larger ink cartridge sizes that reduce ink interventions to automated ink maintenance routines, the T850 and T950 series improve ink efficiency with features that reduce quality issues and waste accrued from ink usage.

Optimised Usage That Saves Energy

Auto-scheduling for on/off usage is just one way the T850 and T950 series reduce energy use. Integrated input, high printing speeds, and the ability to print with fewer clicks contribute to printing efficiency. Ultimately, these printers reduce the time and energy required for printing.

Connectivity and Eco-Friendly Software Options Create Eco-Friendly Workflows

Printers designed for efficiency and high productivity help professionals develop naturally eco-friendly workflows that assist with sustainability efforts. These productivity-enhancing features help businesses reduce the environmental impact of the printing process.

Cloud Printing

The T850 and T950 printer series allow users to work securely and easily submit jobs from anywhere with protection from HP Wolf Pro Security. With the use of HP Click, AEC professionals can store data in the cloud and print from mobile devices, reducing hardware needs and creating more efficient workflows.

Mobile App Integration

hen used with the HP App, AEC professionals can reduce travel between the office and the field. Manage your device and print from virtually anywhere with the use of a mobile or tablet.

Compatibility With Industry Standard Design Software

HP wide format printers and plotters are designed to be compatible with AEC industry-standard software. As a result, businesses can confidently print various forms on different paper sizes without time-consuming setup requirements.

Reach Out to HP Today to Enquire About the DesignJet T850 and T950 Printer Series

Growing concerns about the environmental impact of construction extend far beyond building practices. Printing remains a vital element of AEC design, making sustainable printing solutions crucial for effectively reducing your environmental footprint. Reach out to PSW to learn more about how the DesignJet T850 and T950 series printers can help you meet your sustainability goals.

-

Read more ...

Against a backdrop of global economic uncertainty and fluctuating customer demand, print business leaders face a number of challenges in 2024. However, the large format printing market continues to grow at a steady rate, with technology adoption and new application innovations powering progress. We see several trends that, if approached in the right way, represent opportunities for print service providers (PSPs) to truly thrive in the year ahead.

Automating Workflows With

80% of businesses worldwide automating processes, automation is increasingly important as organisations continue to navigate macro issues such as labour shortages. Automation also boosts the speed print firms can operate at, improves the accuracy of projects, and identifies errors - enabling PSPs to find new ways to streamline operations.

As businesses run digital presses on a 24/7 basis, we expect to see a greater uptake of automated services, and the arrival of new tools to better meet PSP needs. By running businesses and print jobs through platforms like HP Print OS, print firms can unlock previously unseen efficiencies – such as through data analysis of operations, unattended printing or removing repetitive and time-consuming processes.

Whilst the impact of artificial intelligence (AI) is still emerging in the large format sector, in the medium to long term, firms that have already implemented a highly automated infrastructure will be the ones most likely to benefit from AI-influenced advances in the future, such as predictive maintenance.

Sustainability is Profitability

Research shows that 85% of PSP customers now demand sustainable products and practices. Increasing demand for more sustainable goods reflects the consumer shift in values and awareness of the planet’s health. Print firms will continue to recognise this in 2024 and embed sustainable practices where possible.

For this reason, water-based and odourless inks will be sought after, allowing print professionals to say yes to a wider range of jobs, including sensitive indoor environments. The fact more than one in five printers sold in the large format market is an HP Latex device, is proof that this trend is already well underway.

However, print firms will need to look beyond ink and also consider how substrates can be procured and disposed of in a sustainable way. Although progress has been made, the industry must continue to find alternatives to materials such as PVC by investing in new media and research to discover and elevate sustainable solutions.

Greater focus will also be placed on the energy efficiency of printers, as well as extending the lifespan of hardware through easy recycling options when a device reaches end of life. Vendors will be required to step up and support print firms in becoming more sustainable by practice - via programs like HP Planet Partners which provides recycling options for both supplies and hardware.

Print and Protect

Remote working prompted a rise in the volume and variety of malware attacks over the last four years. In an increasingly connected world, businesses will remain vulnerable. This is particularly true for small and medium sized businesses (SMBs), that have lower budgets and a lack of dedicated IT support. Research shows nearly half of SMBs have experienced a cyber security incident within the past year, while over two thirds don’t consider security until after an incident.

As the web of connected devices in office spaces become more sophisticated, and with the advent of AI, the cyber security landscape will become even more complex in 2024.

There is an opportunity to redesign and rebuild a digital ecosystem of tools that help businesses securely manage their end-point devices and data. Printers are often a forgotten endpoint, giving hackers a way into a network. However, with more security-conscious solutions on the market, like HP’s Wolf Security-enabled DesignJet range, SMBs will begin to turn the tide on cyber criminals.

Personalisation and Co-created Content

In an increasingly commoditised world, PSPs will stand out and win business in 2024 with customisable offerings. Brands are seeking ways to differentiate themselves from competitors, while end consumers have shown appetite for personalised or ‘limited edition’ products and experiences. According to research by Sparks & Honey, the expected value of the personalised items market will reach $201bn by 2026, up 49% from 2021. Meanwhile, 70% of shoppers are willing to pay at least 10% more for customised or unique products.

We are seeing creative platforms such as Canva increasing end users’ design capabilities, giving them more ways to personalise print products such as wallpaper. HP recently released a trends report which highlights that the digitally printed wallpaper market is predicted to grow at an annual rate of 23.6% until 2025, reaching a total value of $10.4 billion.

Brands will increasingly base their marketing strategies around ‘user-generated’ or ‘co-created’ content - campaigns that tell the stories of their customers and speak directly to them. According to marketing analytics firm WARC, such approaches have become the number one most effective way to reach Gen Z and millennial audiences.

With the right technology, print firms will be the enablers of this growing trend, and become trusted partners for brands. At a hardware level, firms will need digital print technology capable of handling a range of specifications, delivering short runs, and accommodating fast turnarounds. However, the ecosystem around the device will become even more key in 2024, ranging from the software firms are embedding to manage operations, to ensuring staff are upskilled to harness the latest tools coming to market.

Transforming Our World by Design in 2024

Print businesses have been evolving year on year, and turbulence in recent years has only accelerated the pace of change. Large format print providers are displaying resilience and creativity, and the industry will continue to thrive this year in a more connected, automated, sustainable and secure environment.

About HP

HP Inc. is a global technology leader and creator of solutions that enable people to bring their ideas to life and connect to the things that matter most. Operating in more than 170 countries, HP delivers a wide range of innovative and sustainable devices, services and subscriptions for personal computing, printing, 3D printing, hybrid work, gaming, and more.

-

Read more ...

When it comes to professional sign-making, having a cutting plotter that is fast, efficient, and versatile is an absolute necessity. Enter the Summa S Class 3 – the epitome of precision and flexibility. With a wide array of applications that set your business apart, this cutting-edge machine is a game-changer. The application possibilities are endless, but we summed up the categories where the S Class 3 truly excels!

1. Large Signs Make a BOLD Impression

The Summa S Class 3 is your ticket to making a BIG impact with signage. From crafting captivating floor graphics and stunning wall designs to producing eye-catching window stickers and precise lettering, this machine handles it all with finesse.

Need your message to hit the road? Our roll cutter ensures your graphic vehicle designs are nothing short of head-turning. Seeking privacy? The S Class 3 effortlessly transforms your windows into advertising masterpieces while safeguarding privacy from within. And when it’s about grabbing attention indoors, totems and other interior advertising are a breeze for the S Class 3.

2. Small Text and Intricate Designs: Precision at Its Best

The S Class 3 is your ultimate solution for handling small letters and intricate designs with unparalleled precision. What sets it apart? Summa’s Tangential cutting technology! Unlike traditional drag knives, this innovative tech lifts and reorients the knife in corners, resulting in even sharper and more precise cuts.

But that's not all – the Summa S Class 3 boasts Smart Object Sorting, selecting the most optimal starting point for cutting, and Smart Panelling, ensuring efficient cutting of all objects within a set range.

From promotional items like flawlessly cut keychains and magnets to small signage such as nameplates, directional signs, and room numbers, this machine does it all. Labels and tags, both for products and organisational needs, find their perfection here. And, of course, custom apparel enthusiasts will love the S Class 3 for creating personalised T-shirts, hats, socks, and more.

3. Every Type of Sticker Imaginable: How a-peel-ing!

Take your sticker game to the next level with the S Class 3! This machine optimises your print and cut workflows like never before, thanks to FlexCut.

How does Flexcut work? One length is cut completely through the material, while the other is cut halfway through, creating a perfect tear-off line. This ensures your material stays rigid during transport through the Summa cutter yet remains easy to remove from your design afterwards.

The possibilities are boundless! Whether it's standard vinyl stickers, kiss-cut stickers, die-cut stickers, clear stickers, bumper stickers, holographic stickers, transfer stickers, or window clings and wall/floor stickers, the S Class 3 handles them all with precision and ease.

4. Thick, Thin, and Tough Material

Standard laminated vinyl is not the only material that can be cut with the S Class 3. Thanks to the tangential cutting head, all types of materials of non-standard thickness can be cut. This opens up a whole new array of cutting possibilities!

When we talk about thin materials, we are referring to substances thinner than standard sticker vinyl, like car wraps. In contrast, thick and tough materials (which tend to be the same materials) are materials that can be up to 1.2mm thick, such as laminated vinyl and folding carton.

5. Creasing: When folding under pressure is a good thing

Only available on Summa cutting plotters is the possibility to not only cut but also crease. In fact, the new Performance Head can cut and crease during the same job, i.e. without having to change tools or having to stop the machine.

The creasing function is perfect for short-run applications. For example, to make exclusive gadgets for events or companies in folding carton.

Folding carton is incredibly versatile in its applications. Combining it with the S Class 3 can lead to some great results. For example, you can make some high-quality restaurant menus as well as personalized greeting cards for special occasions. Short-run leaflets, as well as folders, can be made with an S Class 3. Creating customized little boxes is an option, too and can be used to hold small presents or business cards.

About Summa

Every day, for over three decades, Summa has delivered the world’s highest quality vinyl and contour cutters, finishing flatbeds and laser cutters without compromise. Summa provides cutting-edge solutions for the printing, signage, display, apparel and packaging industries.

-

Read more ...

Today HP announced a new 36-inch DesignJet portfolio that simplifies the printing needs of AEC (architecture, engineering & construction) professionals who increasingly work in a hybrid environment - needing a high-quality printing experience, whenever and wherever they are.

The devices will also enable copy shops to better meet the requirements of AEC customers.

With 54% of AEC firms deploying a hybrid work policy, flexible working models are here to stay. This new approach has changed workflows, requiring aspects of the job, including large format printing, to be enabled in a hybrid environment.

Because of this, users need intuitive print technology that meets their technical needs, whether that is printing A3-A1 CAD drawings or architectural boards, all without compromising on security.

“More than ever, AEC pros, or the copy shops that serve them, need easy-to-use tools that help them be more productive and deliver high-quality work - whether they are in the office, at home or somewhere remote,” said Daniel Martinez, General Manager, Large Format Business, HP. “With our new HP DesignJet lineup - alongside software such as HP Click and the HP app - users can print, monitor jobs and check device status from virtually anywhere, as well as collaborate on documents with colleagues.”

With the new 36-inch DesignJet portfolio, HP helps customers to go beyond and run their businesses while achieving their sustainability goals.

Thanks to HP’s Forest First initiative, with every page a user prints with the HP DesignJet T850/T950 or the HP DesignJet XL 3800, HP collaborates with non-profit organisations , to ensure forests are restored.

The HP DesignJet T850/T950 are both made from at least from 35% recycled plastic, use cardboard-based cartridges, and can be scheduled to power on and off automatically to preserve energy consumption. Meanwhile the HP DesignJet XL 3800 is comprised of at least 33% recycled content.

HP has also prioritised cyber-security, with HP Wolf Security protection built into the HP DesignJet T850/T950 and XL 3800. HP Wolf Security provides comprehensive endpoint protection and resiliency that starts at the hardware level and extends across cloud-based software and services – safeguarding an organization’s PCs, printers and people from cyber predators.

With additional Enterprise-level Wolf security features, the HP DesignJet XL 3800 is also the world’s most secure large format printer, based on third-party analysis of security features available on the market.

Solutions For All AEC Requirements

The new HP DesignJet lineup – consisting of three product families - provides several options and features to cater for all AEC user needs, including:

HP DesignJet T850/T950

- Save time by moving effortlessly from A3 to A1 prints, with the A3-to-Large Format integrated device

- High-quality CAD and renders on any size and application

- Simplify remote collaboration with one-click scan and copy workflows from the front panel

HP DesignJet XL 3800

Keep projects moving with the fastest colour printer in its class at 6 A1/D colour pages/min, and first page out in 20 seconds

- Excellent CAD lines and graphics applications in mono and colour

- Optimise space with 20% more compactness

- Perfect for copy shops and enterprises

Availability

The HP DesignJet T850/950 and the HP DesignJet XL 3800 are expected to be commercially available in all major markets starting October 17th and October 30th, respectively.

About HP

HP Inc. is a global technology leader and creator of solutions that enable people to bring their ideas to life and connect to the things that matter most.

Operating in more than 170 countries, HP delivers a wide range of innovative and sustainable devices, services and subscriptions for personal computing, printing, 3D printing, hybrid work, gaming, and more.

-

Read more ...

Today HP Inc. launched the new HP Latex 630 printer series, completing HP’s Latex range and making white ink technology available to Print Service Providers (PSPs) of all sizes. White ink allows users to produce a more impactful range of signage and décor jobs with stunning image quality and colours that jump off the page, creating attention grabbing campaigns for end-customers.

The HP Latex 630-series, as with the rest of HP’s Latex portfolio, allows firms to offer more sustainable printing services: with water-based latex inks that give off negligible chemicals or odours; UL ECOLOGO® and EPEAT® environmental certifications; and carton-based cartridges that reduce plastic by using 100% recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closed-loop process - including post-consumer beverage bottles.

“The new HP Latex 630-series packs our leading latex features, such as white ink, into a more compact and affordable form factor - allowing even the smallest of print businesses to effortlessly deliver high impact signage and décor applications, boosting margins,” commented Daniel Martinez, General Manager, HP Large Format. “Beyond the hardware, we have continued to innovate when it comes to services and solutions, with new cloud-based HP Print OS functionalities giving time-pressed users the ability to process and monitor jobs from virtually anywhere.”

The HP Latex 630 family provides a number of options and features, including:

- A choice of four SKUs

- The HP Latex 630 and HP Latex 630 W – the latter with white ink functionality

- HP Latex 630 and 630 W Print & Cut Plus – giving customers the option of upgrading to a dual-device solution, with print and cut functionality

- Save time – with automated front-loading system and simple, fast load/unload workflows

- Easy re-prints – with in-printer storage of up to 10GB

- Stunning image quality – with HP Pixel Control Technology and new printhead architecture for sharper small text, all at standard speeds of 14m2 (150ft2) an hour

- Software as standard – SAi RIP solution offered out of the box

Win business online and simplify operations

As part of a continued focus on helping PSPs improve productivity and grow their business, HP has also announced HP PrintOS Design & eCommerce – an intuitive web-to-print solution that saves valuable time with simplified print application design capabilities, efficient production paths, and step-by-step guidance on how PSPs can integrate it with an existing e-commerce store.

"We spend a lot of time listening to print providers about what they need to grow, and one key area was evolving their e-commerce capabilities and better connecting the front and back-ends of their business," added Daniel Martinez. “HP Print OS Design & eCommerce is our response, giving PSPs a quick and easy way to enhance their online shop, as well as new ways to process orders and automate jobs.”

The Design & eCommerce solution will be made available in select countries within HP’s PrintOS suite to subscribers of the HP Professional Print Service Plan (PPSP) ‘Plus’ tier, making the PPSP offering more appealing to small and medium sized PSPs. HP’s Professional Print Service Plans are designed to enable business agility, maximize uptime, and to provide learning opportunities and support.

For further information about HP Print OS Design & eCommerce and HP Professional Print Service Plans, please contact PSW Paper & Print Limited.

Availability

The HP Latex 630, HP Latex 630 W, HP Latex 630 Print & Cut Plus, and HP Latex 630 W Print & Cut Plus are expected to be available from September 19th, 2023, in major markets globally.

The HP Print OS Design & eCommerce solution is expected to be available from November in the UK, Spain, Australia and New Zealand. For further information, please contact PSW Paper & Print Limited.

About HP

HP Inc. (NYSE: HPQ) is a global technology leader and creator of solutions that enable people to bring their ideas to life and connect to the things that matter most. Operating in more than 170 countries, HP delivers a wide range of innovative and sustainable devices, services and subscriptions for personal computing, printing, 3D printing, hybrid work, gaming, and more. For more information, please visit: http://www.hp.com.

- A choice of four SKUs

-

Read more ...

The Summa S Class 3 is a state-of-the-art device designed for professional users who demand top performance in their cutting applications and want to explore new opportunities. At the heart of the S Class 3 is its unique True Tangential Cutting Technology, ensuring top-notch performance. The addition of the all-new OPOS Camera with onboard image processing provides ultra-fast mark recognition and processing, making print & cut workflows smoother and more efficient. The performance head is the most advanced in the vinyl cutter series and can now automatically switch between cutting and creasing, perfect for short-run packaging jobs, and setting a new standard in the industry.

High-Precision & Unrivalled Performance

The S Class 2, a proven performer, has been on the market for ten years. It is not only unmatched (still!) by its competition, it is also very much valued by its customers. "For the S Class 3, we kept the good and proven. And while they may look similar under the hood at first sight, a lot has been upgraded. The latest electronics made it possible to achieve faster responsiveness, better data processing, and more precise motor control, resulting in a smoother, faster, and more reliable result.", says Randi Kerkaert, product manager.

Reliable & Versatile Cutting

Nowadays, vinyl cutting is probably not the hottest topic in the Sign & Display industry. "The long lifetime of every Summa vinyl cutter allows sign shops to avoid the need for further investments in vinyl cutting equipment. On the other hand, having a premium cutting plotter available on the work floor remains essential and critical for many businesses", states Christof Van Driessche, CCO at Summa. "A reliable cutting plotter is much appreciated even in an industrial environment. With the introduction of the S Class 3, we aim to provide new opportunities for sign shops to expand their current vinyl cutting businesses and explore new territories, like cardboard cutting and creasing."

The S Class 3 will be available in from the 5th September 2023. Check out all the details of this amazing product, including the barcode workflow with enhanced roll-up system, its Performance Head and the all-new OPOS Camera.

About Summa

Every day, for over three decades, Summa has delivered the world’s highest quality vinyl and contour cutters, finishing flatbeds and laser cutters without compromise. Summa provides cutting-edge solutions for the printing, signage, display, apparel and packaging industries.

-

Darren Haynes is the Operations Manager for the inspiring social enterprise Nuneaton Signs. Darren has been telling us how two Keencut SteelTrak cutting machines have transformed their print-finishing process. Nuneaton Signs is a social enterprise company which provides meaningful employment and training for people with disabilities through the manufacture and sales of signs. 71% of staff have at least one disability or mental health condition, and the organisation reinvest 100% of its profits back into the business to expand the number and quality of opportunities for those it supports. Nuneaton Signs started in 1982 as a sheltered workshop to support and upskill differently abled people. It has an impressive client list of major UK private and public sector organisations, and, as with any company, its clients are looking for quality and value for money. Winning many awards for its activities, Nuneaton Signs recently hit a £4.9 million turnover and aims for £6 million.

Darren told us about the production facility and how they use their two Keencut SteelTraks.

“We bought the first SteelTrak four years ago, and we loved it. We have been growing fast in the last four years. We have 73 members of staff, and with a new flatbed printer which allows us to complete more work, we needed additional cutting capacity. We employ people to do manual work, and the SteelTrak is an ideal tool for us. Four key SteelTrak benefits have made a difference:

Cut out the dust

“The SteelTrak’s ability to cut without dust transforms the cutting process and ensures a quality finish. We can site the area for cutting next to the flatbed printer without any worries about damage.

Initially, we used a vertical wall saw, but when you cut 10,000 foamex signs a month, the dust is everywhere; it’s in the whole building. Static build-up makes the dust stick to all the signs, and dust can potentially damage the printer heads. You are literally dealing with tons of dust a year. You are constantly cleaning the area, and lying vinyl on boards in a dusty area will never give you a good finish.”

Safety

“To start with, the SteelTrak solves the issue of breathing in dust generated by cutting with a wall saw. We have also eliminated the need for hand cutting. We would often cut the thinner 3mm boards with a knife by hand, but we do not need to do that now that we have the SteelTraks on site. The blades are hidden for general safety, so apart from when you change the blade, everything is away from your hands.”

Robust

“I estimate our SteelTraks cut three boards a minute for eight and a half hours daily. They are incredibly robust. We cut everything from ACM to 10mm Foamex. We also work with our Enviro range of 100% PVC-free boards. We are working hard to promote more recycling in our industry. We have been working to convert clients to environmental boards so that used signs can be placed into normal recycling waste sites. The key is for companies to swap totally to Enviro board so that they know that everything they use can be recycled.”

Easy-to-use

“We employ and offer internships to people with a wide range of abilities. We have found that individuals who cannot work in other areas can master the SteelTrak. Having a machine that is so easy to use is a real benefit. Most people can use a SteelTrak without much input, and there is a huge sense of achievement in creating a set of well-finished signs. For some of the extra maintenance tasks like renewing blades or the sightline strip, we may get a more experienced operator to help, but for general use, the SteelTrak is easy to use. After a day, people are an expert at cutting with a SteelTrak.”

To learn more about the benefits of using the Keencut SteelTrak in your production click here

To find out more information about Nuneaton Signs click here

Read more ...Posted: August 24, 2023| -

Read more ...

Onyx Graphics, Inc., a leader in providing wide-format software solutions, today announced the global availability of ONYX 22.5, the company's newest version release of industry-leading wide-format RIP and print workflow software that was previewed with great acclaim at FESPA Global in Munich, Germany earlier this year.

ONYX 22.5 introduces ONYX Archive for effortless backup, search, restoration, and management of print jobs, and is connected directly to the main ONYX user interface as a standard feature for the entire portfolio of ONYX RIP and print workflow software solutions. "We're thrilled to unveil ONYX 22.5 to the World," said Matt Crawford, President and CEO of Onyx Graphics, Inc. "Whether you're a small-scale operation or a global enterprise, this remarkable tool revolutionises print production and will streamline workflows like never before."

This latest release builds upon industry-leading ONYX 22 software that introduced new tools for easy, everyday automation and colour output accuracy for any printer/media combination. In addition to ONYX Archive, ONYX 22.5 introduces a new user experience for faster setup and configuration of XY trimmers, Adobe PDF Print Engine (APPE 6.1), and new colour updates for predictable output. "ONYX 22.5 does more than bring new features to market," said Jonathan Rogers, Senior Manager of Global Marketing and Communications at Onyx Graphics. "This milestone release represents our unwavering commitment to pushing the boundaries of what is possible in wide-format printing."

Highlights of ONYX 22.5 include:

- ONYX Archive to back up, search, and restore jobs for future use

- XY Trimmer updates for simpler workflows

- Adobe PDF Print Engine (APPE 6.1)

- New cutter device support for KALA, Ellerhold Poster-Cutter 2050, and Fotoba cloud barcodes

- New colour device support for Nix Spectro 2, X-Rite eXact2, and Barbieri Textile

- Spot colour replacement using the ONYX Colour Reference Library

- ONYX Colour Reference Library and cut paths now included in CorelDraw

- ColourCheck baseline tests for Media Manager

- Image controls for textile and wallpaper printing

- QR code scaling for dynamic print labels

Availability

The next version release of ONYX software is available now, covering the entire product portfolio of ONYX solutions, including ONYX Thrive print workflow software, ONYX Go, the company's RIP software subscription, ONYX PosterShop, and ONYX RIPCenter RIP software. It will be available to all ONYX Advantage customers by requesting a product update, is included as part of ONYX Go subscriptions, and to all other customers through a license or subscription purchase.

About Onyx Graphics, Inc.

Leading the market since 1989, Onyx Graphics is dedicated to helping customers increase productivity, reduce costs, and gain a competitive edge with superior software solutions for the print industry. Innovative, productive, and delighted customers around the globe help motivate the company to develop and enhance its leading-edge technologies. Global channel partnerships and longstanding relationships with printer manufacturers position Onyx Graphics as a market leader in powerful, reliable, large-format printing workflow and print business software solutions.

-

Read more ...

Practices need technology that is adaptable, secure and sustainable enough to flex around ever-evolving business needs and lifestyles they need innovations that make their working lives easier and more productive, while reducing operational costs. Whatever the challenge, HP large format printers have the answer.

Ensuring seamless working

Integrating large format print seamlessly with the workflows and lifestyles of architecture, engineering and construction (AEC) professionals helps to build flexibility into work/life infrastructure.

HP Click software and the HP Smart App provide a seamless remote printing experience with A1-A3 automatic printing using the HP DesignJet T200, T600 series and Studio plotters.

Security built in

HP delivers a better printing experience to protect the ideas and people we value most. The most secure printers on the market, HP large format printers have embedded security designed to protect networks.

From HP Secure Boot and HP Trusted Platform Module (TPM) security on the inside to Role Based Access Control and Front Panel Access Lock on the outside, HP large format printers keep businesses safe.

Working sustainably

With environmental sustainability being a key strategic objective for today’s businesses, the technology solutions they employ need to fulfil their sustainable agenda. Fifty leading global AEC firms have agreed to pursue a strategy of zero CO2 emissions by 2040, with major carbon reduction goals for 2030.

HP’s plotters are designed with the environment in mind, from printers made with less plastic and global recycling initiatives to cartridges made of recycled materials and water-based inks. Original HP ink cartridges and printheads can be recycled through the HP Planet Partners programme for free.

Quality as standard

HP’s DesignJet and PageWide XL large-scale printer families are ideal for offices or workspaces of any size. They are robust, fast and agile. They enable individuals or teams to produce large-format plans, CAD drawings and renderings with more line accuracy and colour representation (gamut) than competitors, while synchronising with modern BIM software. HP’s innovations allow architects and designers to maintain productivity, collaboration and relationships with team members, enabling them to work more sustainably and effectively.

About HP

HP Inc. (NYSE: HPQ) creates technology that makes life better for everyone, everywhere. Through our product and service portfolio of personal systems, printers and 3D printing solutions, we engineer experiences that amaze.

Skip to Content

- Create an Account

- Offers for you

+44 (0) 1527 853 136